Rockford Systems, LLC

4Call: 1-800-922-7533

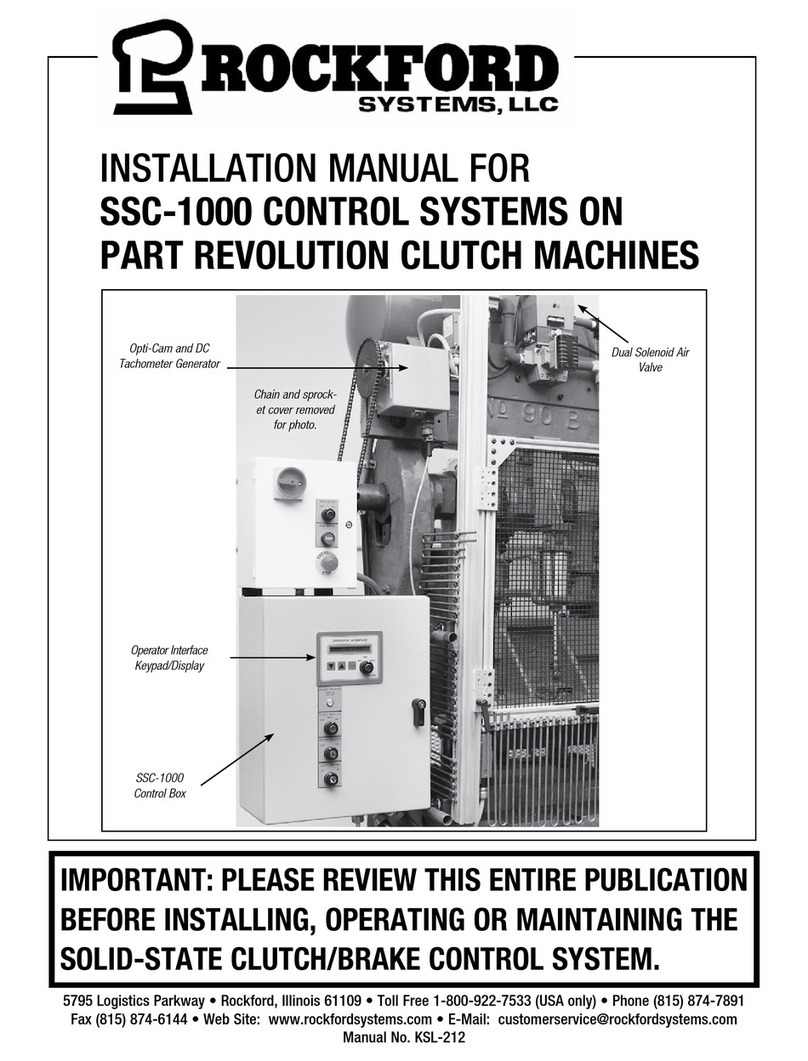

SSC-1500 Part Revolution Solid-State Control

SECTION 1—IN GENERAL

ANSI SAFETY STANDARDS FOR MACHINES

The most complete safety standards for machine tools are published

in the ANSI (American National Standards Institute) B11 series. The

following is a list of each ANSI B11 Standard available at the printing

of this publication.

B11.1 Mechanical Power Presses

B11.2 Hydraulic Presses

B11.3 Power Press Brakes

B11.4 Shears

B11.5 Iron Workers

B11.6 Lathes

B11.7 Cold Headers and Cold Formers

B11.8 Drilling, Milling and Boring

B11.9 Grinding Machines

B11.10 Sawing Machines

B11.11 Gear Cutting Machines

B11.12 Roll Forming and Roll Bending

B11.13 Automatic Screw/Bar and Chucking

B11.14 Coil Slitting Machines

B11.15 Pipe, Tube and Shape Bending

B11.16 Metal Powder Compacting Presses

B11.17 Horizontal Hydraulic Extrusion Presses

B11.18 Coil Processing Systems

B11.19 Safeguarding Performance Criteria

B11.20 Safety Requirements for Manufacturing Sys-tems/Cells

B11.21 Lasers

B11.22 CNC Turning Machines

B11.23 Machining Centers

B11.24 Transfer Machines

B11/TR1 Ergonomics

B11/TR2 Mist Control

B11/TR3 Risk Assessment

B11/TR4 Control Reliability for Design, Construction, and Validation

of PESs

R15.06 Robotic Safeguarding

These standards can be purchased by contacting:

American National Standards Institute, Inc.

11 West 42nd Street

New York, New York 10036

Phone: (212) 642-4900

Fax: (212) 302-1286

www.ansi.org

OR

Association of Manufacturing Technology (AMT)

7901 Westpark Drive

McLean, Virginia 22102

Phone: (703) 827-5211

Fax: (703) 893-1151

www.mfgtech.org

Safety References

OSHA’S ACT AND FEDERAL REGULATIONS

Since the enclosed equipment can never overcome a mechanical

deficiency, defect or malfunction in the machine itself, OSHA

(Occupational Safety and Health Administration) has established certain

safety regulations that the employers (users) must comply with so that

the machines used in their plants, factories or facilities are thoroughly

inspected and are in first-class operating condition before any of the

enclosed equipment is installed.

1. U.S. Government An Act – Public Law 91 - 596, 91st

Congress, S. 2193, December 29, 1970

Duties:

Sec. 5. (a) Each employer —

(1) shall furnish to each of his employees employment and a place

of employment which are free from recognized hazards that

are causing or are likely to cause death or serious physical

harm to his employees;

(2) shall comply with occupational safety and health standards

promulgated under this Act.

(b) Each employee shall comply with occupatioal safety and

health standards and all rules, regultions, and orders issued

pursuant to this Act which are applicable to his own actions

and conduct.

2. OSHA’s Code of Federal Regulations, Subpart O, that an

employer (user) must comply with include:

Section 1910.211 Definitions

Section 1910.212 (a) General Requirements for all Machines

Section 1910.217 Mechanical Power Presses

Section 1910.219 (b)(1) Mechanical Power-Transmission Apparatus

(Flywheel and Gear Covers)

3. OSHA’s 29 Code of Federal Regulations, Subpart J 1910.147

The Control of Hazardous Energy (Lockout / Tagout)

4. OSHA Publication

“General Industry Safety and Health Regulations Part 1910,” Code

of Federal Regulations, Subpart O

This publication can be obtained by contacting:

Superintendent of Documents

US Government Printing Office

P.O. Box 371954

Pittsburgh, PA 15250-7954

Phone: (202) 512-1800

Fax: (202) 512-2250

www.gpo.gov

(Continued on next page.)