Rockford Systems, LLC

Call: 1-800-922-7533 5

SECTION 1—IN GENERAL

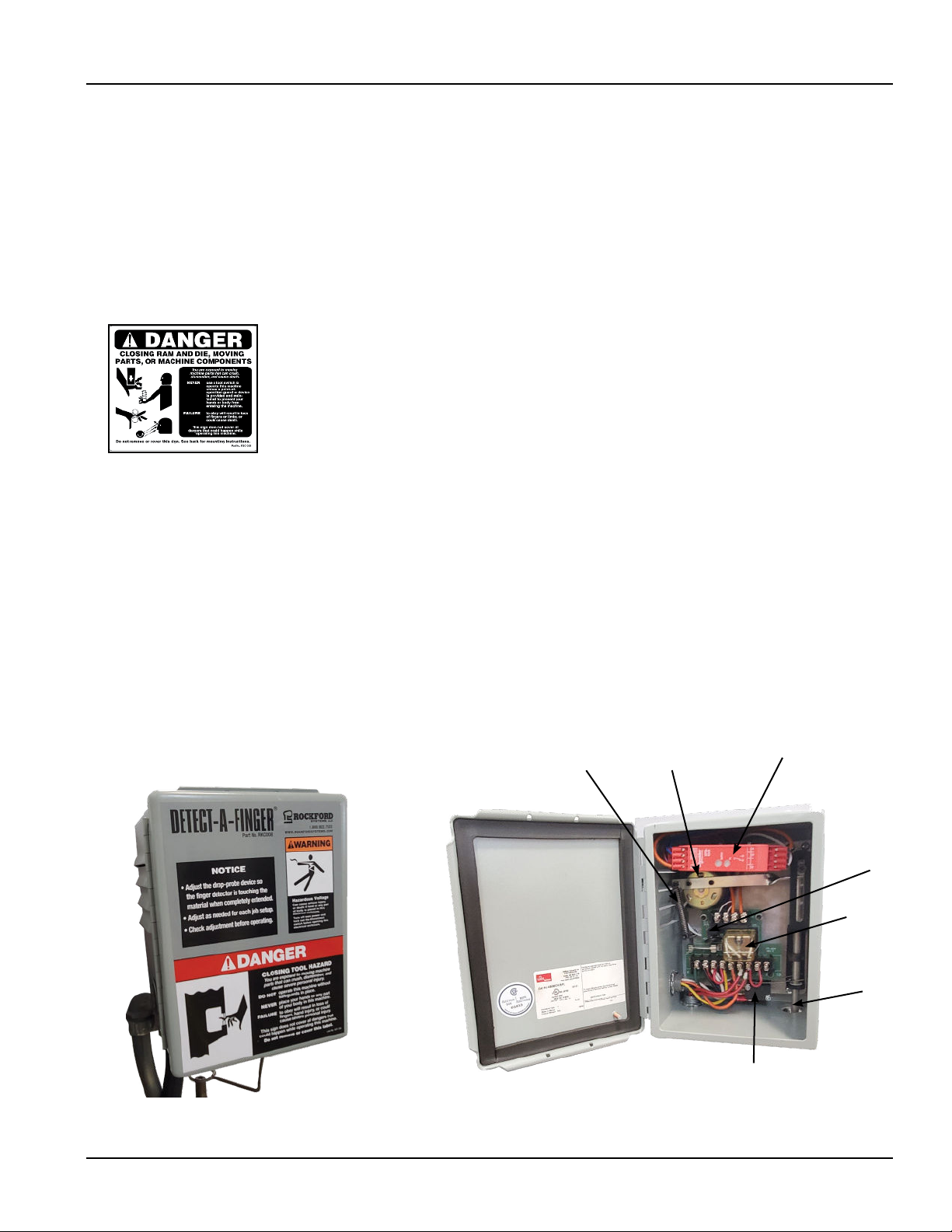

Detect-A-Finger™ Gen II Drop Probe Device - Riveter

Do Not Operate This Machine

Until You Read and Understand the

Following Safety Precautions.

Never operate this machine until you understand that this

machine is dangerous and if you place your hands, or any

part of your body in this machine it could result in the loss of

fingers, limbs or even death.

Never operate this machine without the use of a guard or

safety device that will always protect you from bodily injury.

Never use a foot switch to operate this machine unless

a point-of-operation guard or device is provided and

properly maintained.

Never “ride” the foot pedal or foot switch. Never rest your

foot on top of the foot pedal or inside the foot switch. Always

remove your foot completely from the foot pedal or foot

switch after each cycle and any time you are not intending

to trip the machine.

Always use hand tools for feeding or retrieving material

from the point of operation or any other hazardous part of the

machine. Never reach through or into die area for any reason.

Never operate this machine unless you feel you have been

fully trained and have received and understand all operating

instructions. Make sure you know how the machine works

and how it is controlled.

Never operate this machine until you test the machine with its

guard or safety device before you start or restart production.

Do not begin operating the machine unless you are sure the

safeguarding is adjusted properly and working correctly. If you

are not sure call your supervisor.

Never operate this machine if it is not working properly or if

you notice any unusual noise or change in the performance

of the machine. Stop operating the machine immediately and

advise your supervisor.

Never operate this machine with pullbacks unless they are

adjusted properly for you. Have your supervisor show you

manually that when the ram descends the pullbacks will

pull your fingers clear of any pinch points. Always wear your

wristlets properly and securely.

Never operate this machine with pullbacks without reading

and understanding the instructions. Instructions must be kept

with the pullback device at all times and made available to

you. Obtain, read and follow these instructions.

Never operate this machine unless two-hand trip, two-hand

control or presence sensing device are installed correctly and

at the proper safety distance. Consult your supervisor should

you have any questions regarding the proper safety distance.

Never tamper with, rewire or bypass any control, component

or safeguard on this machine.

Always wear safety glasses, ear protection and any other

personal protection equipment needed when operating this

machine.

Be sure all persons are clear of the machine before it is

cycled, especially when multiple operators are present. Do

not operate machine unless you and every operator and/or

helper are protected from injury by a guard or safety device.

Always stay alert (don’t daydream) and never operate this

machine while under the influence of alcohol or any other drug

including prescription medications.

Maintenance and Die Set-Up Personnel: Never work on

this machine unless power is off, flywheel is at rest, safety

blocks are used between dies, ram and bolster plate and

all energy (electrical, air, hydraulic, etc.) are in a zero state.

NOTICE TO EMPLOYER: A copy of this “Operator Safety Precautions” must be given to all operators (including die set-

up people, maintenance personnel and supervisors) of this machine. A copy should also be hung on the machine

readily accessible and visible to the operator. Additional copies of this precaution are available upon request.

Just call or write.

IMPORTANT: Where a language barrier or insufficient schooling would prevent a person from reading and understand-

ing the contents of this Operator Safety Precaution, you should either translate this information or have it read or

interpreted to the person, with assurance that it is understood.

THIS PRECAUTION MUST BE REVIEWED DAILY.

(Continued on next page.)

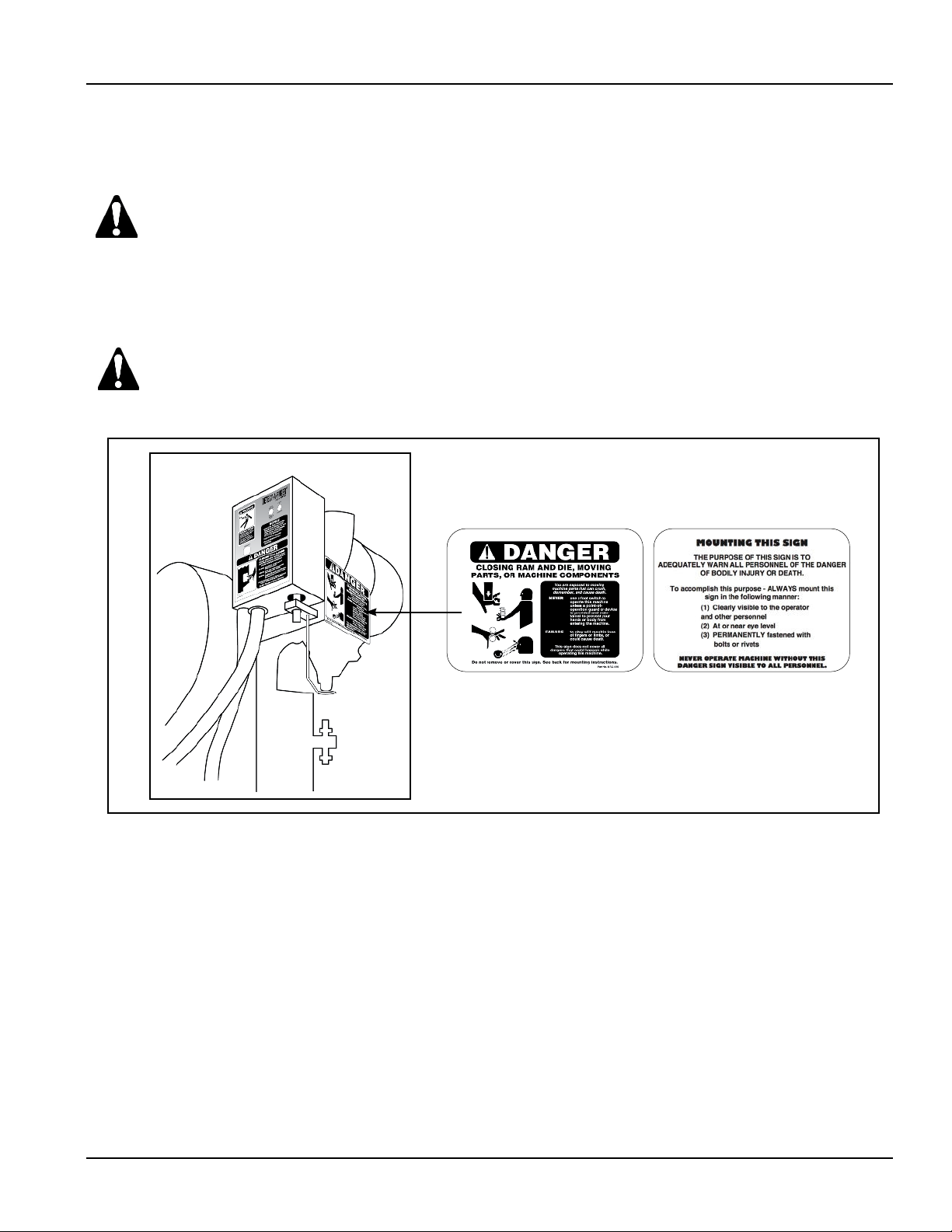

Accompanying this equipment is an 8-1/2”

x 11” operator safety precaution pamphlet,

Part No. KSC000, for anyone operating the

machine where this equipment will be

installed. This precaution pamphlet is to be

given to all operators, including setup people,

maintenance personnel and supervisors.

This pamphlet should also be attached to

the machine, readily accessible and visible

to the operator. (A hole in the corner of this

precaution pamphlet is provided for attaching

purposes.) Additional copies of this precaution

are available. Please call, e-mail, write, fax, or

use the order form found on a later page in

this manual.

When a language barrier or insufficient

education prevents a person from reading or

understanding the contents of this operator

safety precaution pamphlet, you should either

translate this information or have it read or

interpreted to the person. Make sure that

the person understands the information. To

order this pamphlet in Spanish, use Part No.

KSC000S; in French, use Part No. KSC000F.

This precaution pamphlet must be reviewed daily.

Operator Safety Precaution Pamphlet (Attachment for machine operators)

Front

1

2

3

4

5

6

7

8

10

11

16

15

14

13

12

9

Back