2

>Always confirm that you are using the most recent version

of the Instructions and safety warnings for your product. To

find the most recent version, find the product page on

Rockler.com and click on the link to the Instructions.

>For any tool used in conjunction with this product, always

read, understand and follow the instructions and safety

warningsintheowner’smanualforthattool.Ifyoudo

nothavetheowner’smanual,obtainonefromthetool’s

manufacturerbeforeusingitwiththisproduct.

>Before using this product, review and verify that all

toolstobeusedwithithavesafetyequipment

installed and are in proper working order as

definedbythetools’owner’smanuals.

>Do not use this product until you have read and

are confident you understand:

• ProductSpecificSafetyWarnings(below);

• AssemblyandSetup(pp.4-7);

• InstructionsforUse(pp.7-8).

>Remain alert and use good judgment when using

this tool. Do not use this tool if you are in any way

impairedbymedications,alcohol,drugsorfatigue.

>Dress appropriately and remove all jewelry, secure

looseclothingandtieuplonghairbeforeusing

this tool.

> Itisthesoleresponsibilityofthepurchaserofthis

product to ensure that any third party whom you

allow to use this product reads and complies with all the

instructions and safety precautions outlined in this

manual prior to use.

>Maintain these instructions and warnings as long as

youowntheproduct.Keepthisbookletinaplacewhere

itwillbereadilyavailableforreference.

>Theuserassumesallriskandresponsibilityforthe

proper use of this product and for ensuring product

suitabilityforintendedapplication.

>Always wear safety glasses in compliance with ANSI

safety standards and hearing protection and follow all

standard shop safety practices, including:

• Keepyourworkareawelllitandclean;

• Unplugallpowertoolsbeforemakingany

adjustmentsorchangingaccessories;

•Use dust collection tools and dust face masks to

reduceexposuretodust;

• Useaccessorysafetyequipmentsuchas

featherboards,pushsticksandpushblocks

wheneverappropriate;

•Do not use power tools in explosive

environments (e.g., in the presence of

flammableliquids,fumesordust);

• Keepchildrenandbystandersawayfrom

thetooloperatingarea;

•Maintain proper footing at all times and

donotoverreach;

•Do not force the tool.

>These warnings and instructions do not represent the

totalofallinformationavailableregardingtoolsafety,

useandtechnique.Pleasereadthefullmanualbefore

using this product and always seek out opportunities to

learn more and improve your skills and knowledge.

Thistoolisdesignedforspecificapplicationsasdefinedintheinstructionsandshouldnotbemodifiedand/orusedforanyother

applications.BeforeusingtheTableSawSmallPartsSled,read,understandandfollowallinstructionsandsafetyinformationpro-

vided. KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

GENERAL SAFETY WARNINGS

>ThisTableSawSmallPartsSledmustbeusedonly

ontablesawswith3/4"x3/8"miterslots.Useofsled

with an improperly sized miter track may result in

sliding,stickingand/orinjury.

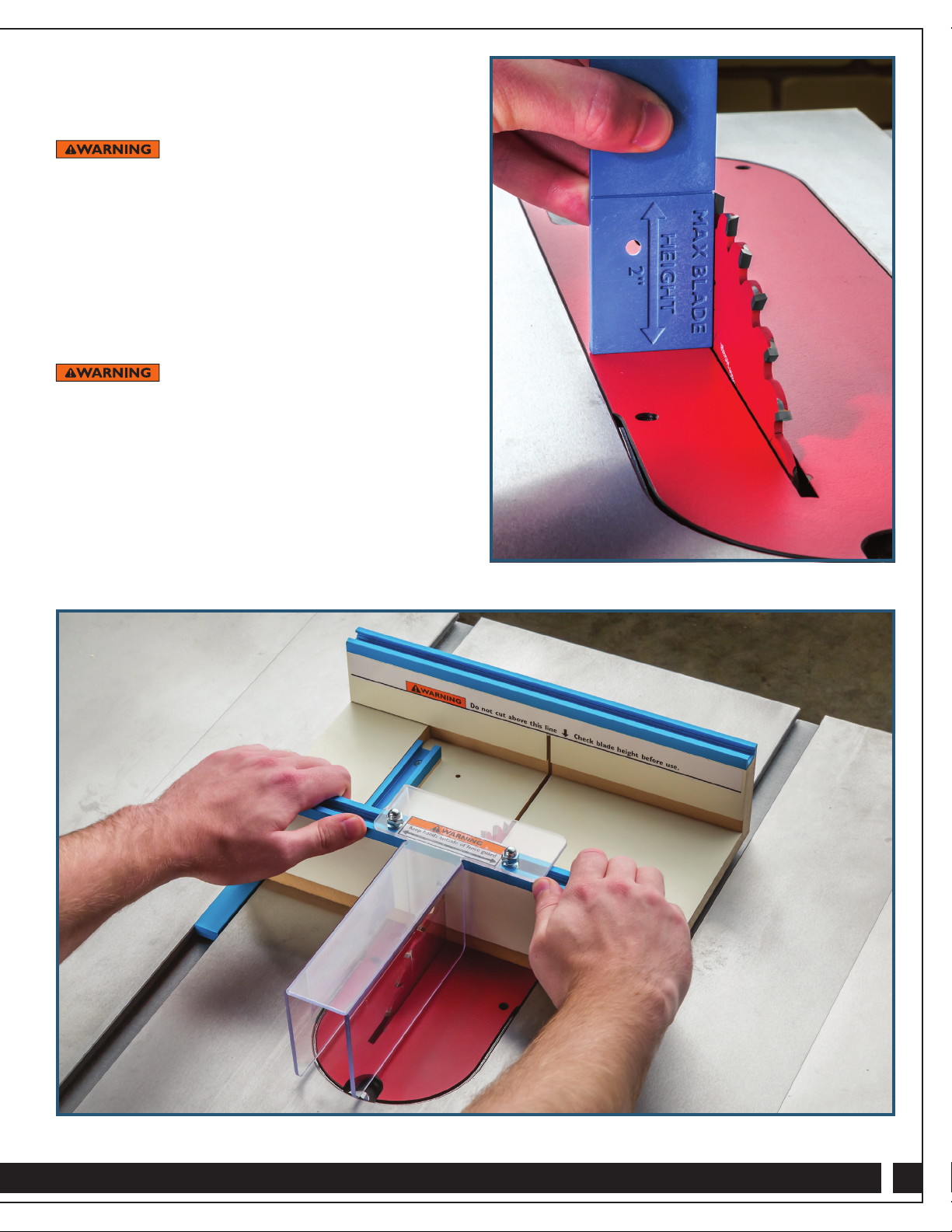

> Thebladeofthetablesawmustbesetnohigher

than2"fromthesurfaceofthetablesaw.Blades

setabove2"couldtearintothesled’supperrailing

and cause injury.

>Do not use this sled to cut stock pieces greater than

1"thickormorethan51⁄2"wide.

>Never use the sled without first inserting the

SafetyMiterStopinthetablesaw’smitertrack

andtighteningtheknob.TheSafetyMiterStop

shouldbepositionedinfrontofthesledsothesled

stopsinthemitertrackbeforeitmovessofarforward

thatthebladeisexposedbeyondthesled’splastic

Blade Guard.

> Removetablesawbladeguardandrivingknifeprior

touseofsledandreinstallbothaftercompleting

sled use.

>For straight 90° cuts only.

> Foruseontablessawswheretheinsidemiterslot

is over 21⁄2"fromtheblade.

PRODUCT SPECIFIC SAFETY WARNINGS

Drilling, sawing, sanding or machining wood

productscanexposeyoutowooddust,asubstanceknown

ot the State of California to cause cancer. Avoid inhaling

wood dust or use a dust mask or other safeguards for

personal protection. For more information go to

www.P65Warnings.ca.gov/wood.