6Rockwell Automation Publication 6300V-UM001B-EN-P - October 2023

Preface

Additional Resources These documents contain additional information concerning related products from Rockwell

Automation. You can view or download publications at rok.auto/literature.

ASREM

Resource Description

ASEM 6300B Box PC and 6300T Thin Clients User Manual,

publication 6300B-UM001

Provides details on how to configure, operate, and troubleshoot the ASEM 6300B book mount box PCs

and 6300T book mount box thin clients.

ASEM 6300M Panel Monitor User Manual, publication 6300M-UM001 Provides details on how to configure, operate, and troubleshoot the ASEM 6300M panel monitors.

ASEM 6300PA Panel PC User Manual, publication 6300-UM002 Provides details on how to configure, operate, and troubleshoot the ASEM 6300PA panel PCs.

ASEM 6300 Industrial Computer and Monitor Specifications

Technical Data, publication 6300-TD001 Provides technical specifications for ASEM 6300 industrial computers and monitors.

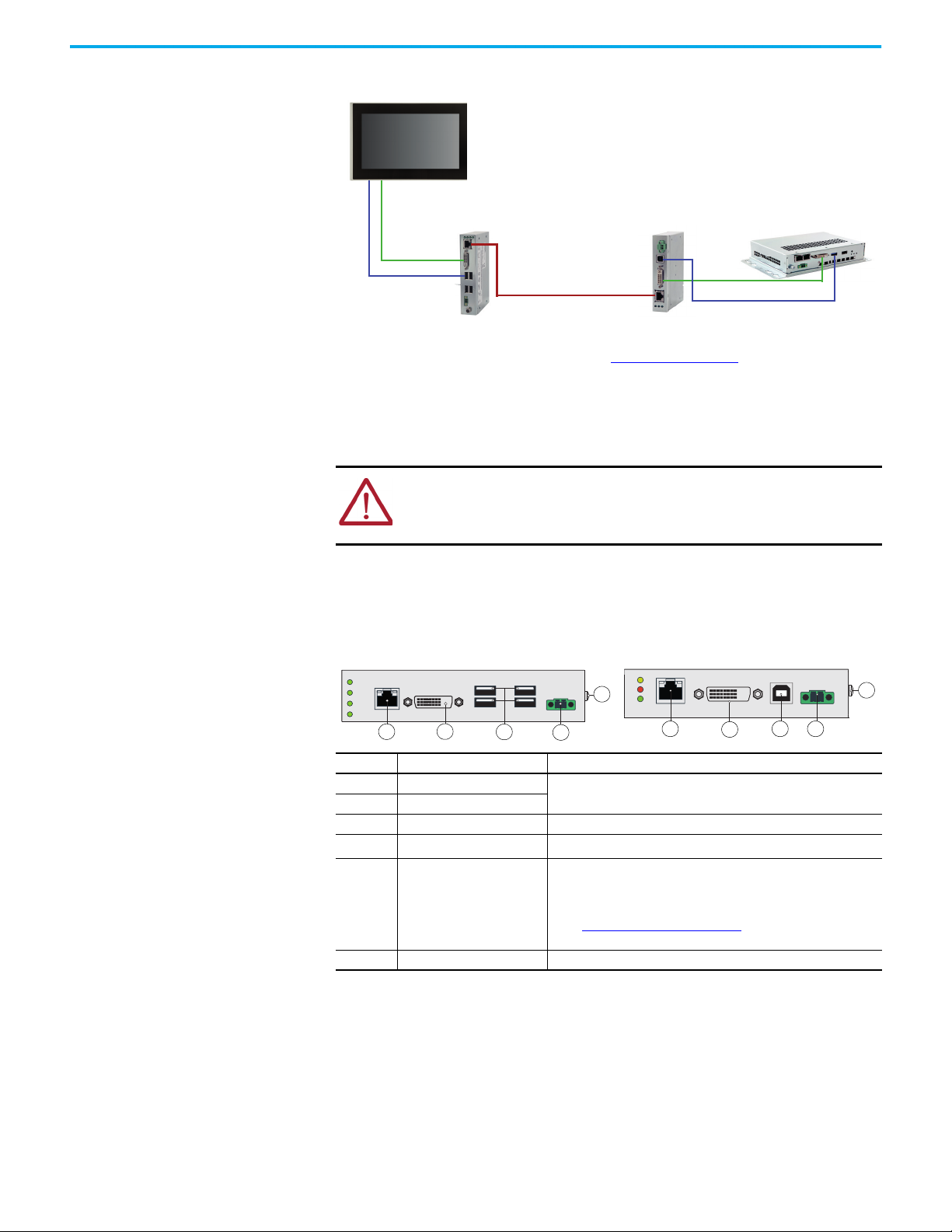

ASEM RVL Receiver, publication 6300V-IN004 Provides installation instructions to mount and connect your ASEM RVL receiver to other components.

ASEM RVL Transmitter, publication 6300V-IN005 Provides installation instructions to mount and connect your ASEM RVL transmitter to other

components.

ASEM 6300V Industrial Computer and Monitor Accessories,

publication 6300V-PC001 Provides product information of accessories for 6300 industrial computers and monitors.

American Standards, Configurations, and Ratings:

Introduction to Motor Circuit Design, publication IC-AT001 Provides an overview of American motor circuit design based on methods that are outlined in the NEC.

EtherNet/IP™ Network Devices User Manual, ENET-UM006 Describes how to configure and use EtherNet/IP devices to communicate on the EtherNet/IP network.

Ethernet Reference Manual, ENET-RM002 Describes basic Ethernet concepts, infrastructure components, and infrastructure features.

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1 Provides general guidelines for installing a Rockwell Automation® industrial system.

Industrial Components Preventive Maintenance, Enclosures, and

Contact Ratings Specifications, publication IC-TD002 Provides a quick reference tool for Allen-Bradley® industrial automation controls and assemblies.

Product Certifications website, rok.auto/certifications. Provides declarations of conformity, certificates, and other certification details.

System Security Design Guidelines Reference Manual, publication

SECURE-RM001

Provides guidance on how to conduct security assessments, implement Rockwell Automation

products in a secure system, harden the control system, manage user access, and dispose of

equipment.

UL Standards Listing for Industrial Control Products,

publication CMPNTS-SR002

Assists original equipment manufacturers (OEMs) with construction of panels, to help achieve

conformity to the requirements of Underwriters Laboratories.

Safety Guidelines for the Application, Installation, and Maintenance

of Solid-state Control, publication SGI-1.1

Designed to harmonize with NEMA Standards Publication No. ICS 1.1-1987 and provides general

guidelines for the application, installation, and maintenance of solid-state control in the form of

individual devices or packaged assemblies that incorporate solid-state components.