Rola-Chem Digital Controller PN 554212 11/22/06 Page: 5 of 16

2.0 Description and Specifications

2.1 General Description

The controller is a microprocessor-based chemical automation system,

which continuously monitors and maintains the pH balance in a

swimming pool or spa.

The pH is displayed using sun-bright light emitting diodes. The pH

levels is continuously monitored and displayed on the controller’s front

panel. The pH controller has been designed to be user friendly. One

MODE button and three SET buttons allow the operator to easily set

parameters.

The pH display range is 6.8 to 8.2 with a .1 unit resolution. The pH set

point is adjustable from 7.0 to 8.0 in .1 pH steps, with a factory default

set point of 7.4 pH. During a feed cycle, the feed lamp will blink when

chemicals are being feed and illuminate continuously during the feed

delay portion of the feed cycle. The Alert lamp will flash when the pH

reading is higher or lower than the factory set limits for more than 10

minutes and prevent the feeding of pH chemicals.

The feed cycle is a timed based ‘feed then delay’ system. The

controller has a series of fixed feed times (0.6 to 900 sec.) with

associated delays as well as a constant feed mode (con). A feed cycle

consists of a feed time plus a delay time. Example, a 30 second feed

time followed by a five-minute delay would have a 5½ minute feed

cycle. The chemical feeder dispenses chemical only during the feed

time portion of the cycle and then waits for a delay period to allow for

chemical to dispense throughout the swimming pool or spa.

Overfeed alert occurs after 120 minutes ‘continuous’ feed and 30

cycles in timed feed mode. Feeders will be disabled and display will

flash (requiring reset).

The controller incorporates an internal non-volatile memory in which

all factory default settings as well as field-modified settings are stored.

The internal memory is not affected by power interruption and requires

no backup battery.

The pH output is capable of handling 5 amps at 120 Volt AC. The

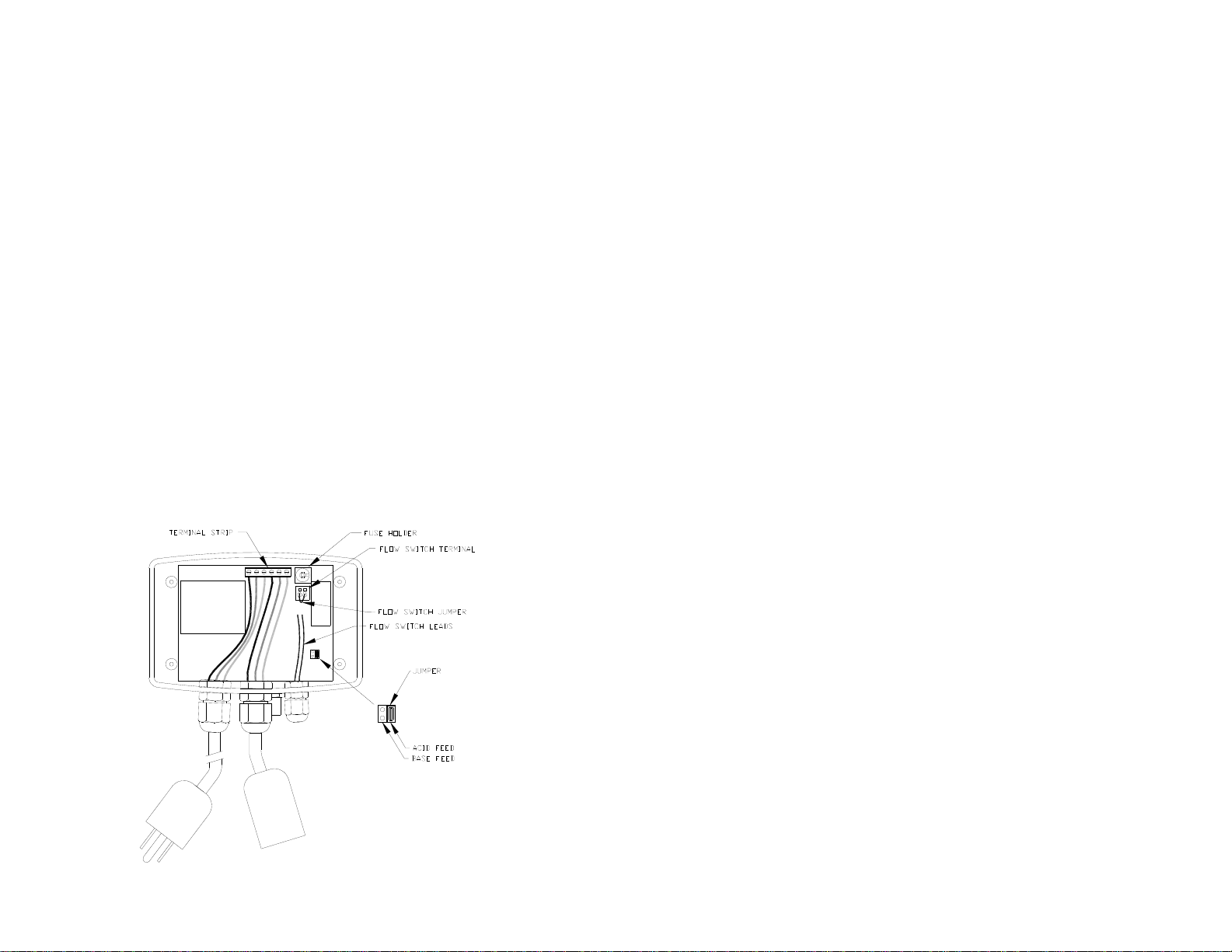

relay output is fused and transient protected. An internal terminal strip

is provided for field wiring of the controller. The internal step-down

transformer has a class-two energy limiting rating to provide for

electrical safety.