Romer®Labs, Inc.

Page 9of 17

Romer®Labs, Inc.

Sampling Procedures for Mycotoxin Analysis

Proper sampling and sample preparation is the foundation of quality mycotoxin testing. This

is the most crucial step in obtaining accurate mycotoxin test results and is very often

overlooked. Without a properly obtained and prepared sample, mycotoxin test results will

have a high degree of analytical variability.

Please consult your Romer®Labs, Inc representative for a copy of the Romer®Labs, Inc.

Guide to Mycotoxins, Volume 2 entitled “Sampling and Sample Preparation for Mycotoxin

Analysis” This publication outlines the proper procedures for sampling and sample

preparation.

The first objective is obtain a representative sample of whole grain, finished feed or meal from

rail cars, truck lots, storage bins, or feeding pans and troughs.

A. Sampling Equipment:

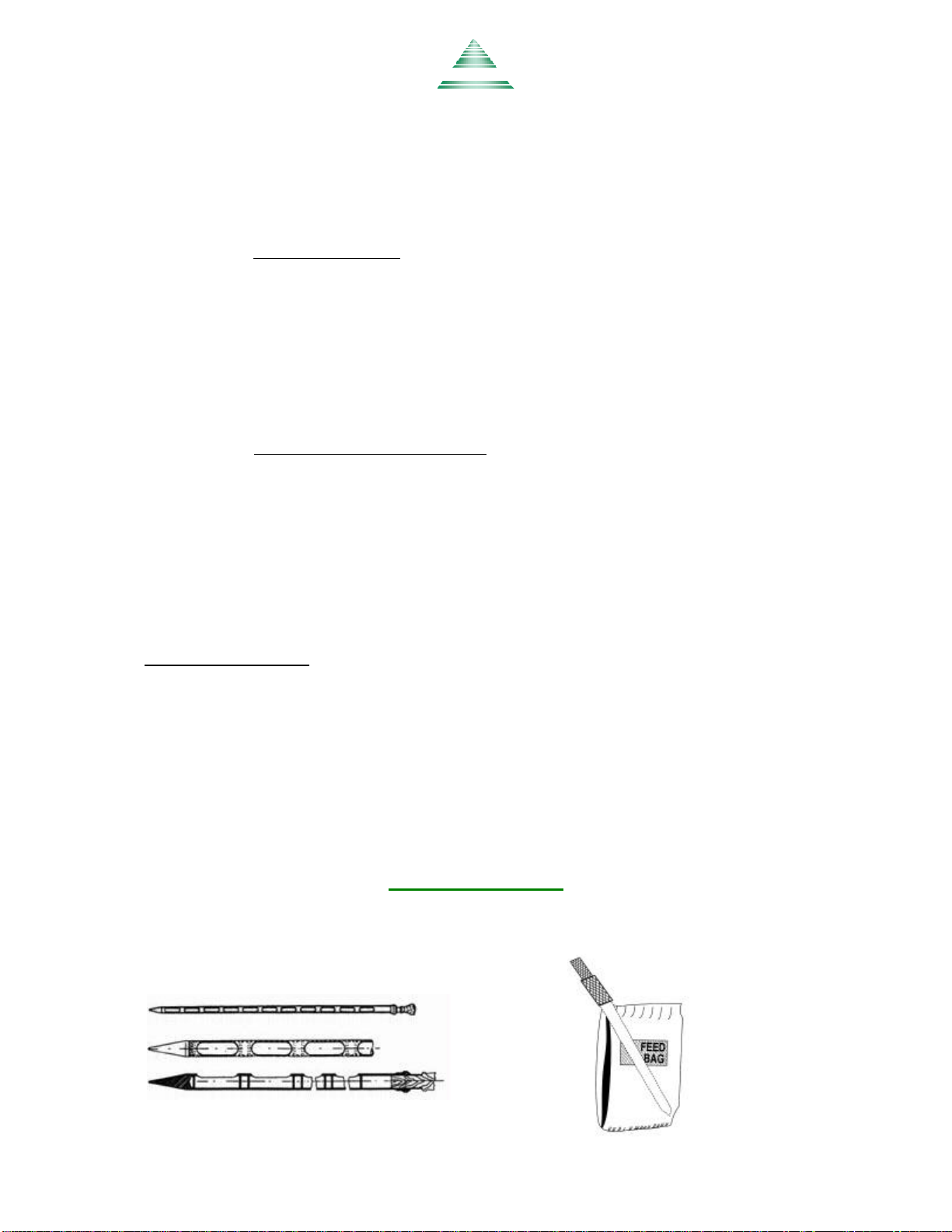

1. Manual Sampling:

•Grain probe or trier (barges, box cars, trucks, hopper containers -see Fig. 1)

•Bag trier (sacked grains -see Fig. 2)

•Pelican sampler (sampling grain in a falling stream)

2. Pneumatic or Hydraulic Probes (terminal elevator or processing plant probe)

3. Mechanical sampling systems

•Diverter-type (automatic sampling of sections or cuts of entire grain flow)

•Point-type (auger sampling of powdered commodities)

B. Sampling Patterns (large grain carriers, storage bins or troughs):

1. Flat-bottom trucks or trailers containing grain more than 4 feet (1.2 m)

deep should use a7-probe pattern with each trailer treated as a separate load.

Flat-bottom trucks or trailers containing grain less than 4 feet (1.2 m) deep

should use a 9-probe pattern (Fig. 3)

2. Hopper car (3-compartment, through or door type), insert probe vertically

at a 10-degree angle in the center or slightly off center in order to miss the cross

beam (Fig. 4)

3. Lift-top and roll-top barges, draw the first probe 4 feet from the stern end

of the barge and 7 feet from the side. Take remaining probes at 15-foot intervals

to the bow end of the barge. The last probe is taken 4 feet from the box end and

7 feet from the side (Fig. 5)

4. Storage Bins should use automatic pneumatic or mechanical sampling

equipment or an adequate probe. If this is not possible, collect 5 probes of feed

or meal or 9 probes of whole grain according to the sampling pattern (Fig. 6).

Collect about 0.5 lbs. from the bottom of the bin using an auger and combine

this with the probed sample. If moisture accumulation is suspected, use the

probe pattern (Fig. 7) to collect potentially moist material from the edges of the