CONTINUOUS LINE FURLERS

Series 80 Furler Manual

3

ACCESSORIES

RS208010 – Top Swivel

The top half of the continuous line furling system, the top swivel is matched to furler load rating and the fork is

designed for use with our dedicated torsion line thimble. It features a maintenance free, factory sealed bearing,

retained clevis pin and snag-free low prole shackle pin head.

RS208020 – Snap-Shackle

Simply replace the shackle on the furler or top swivel with the snap-

shackle adaptor for quick attachment of the furler to your bow tting or

the top swivel to your halyard.

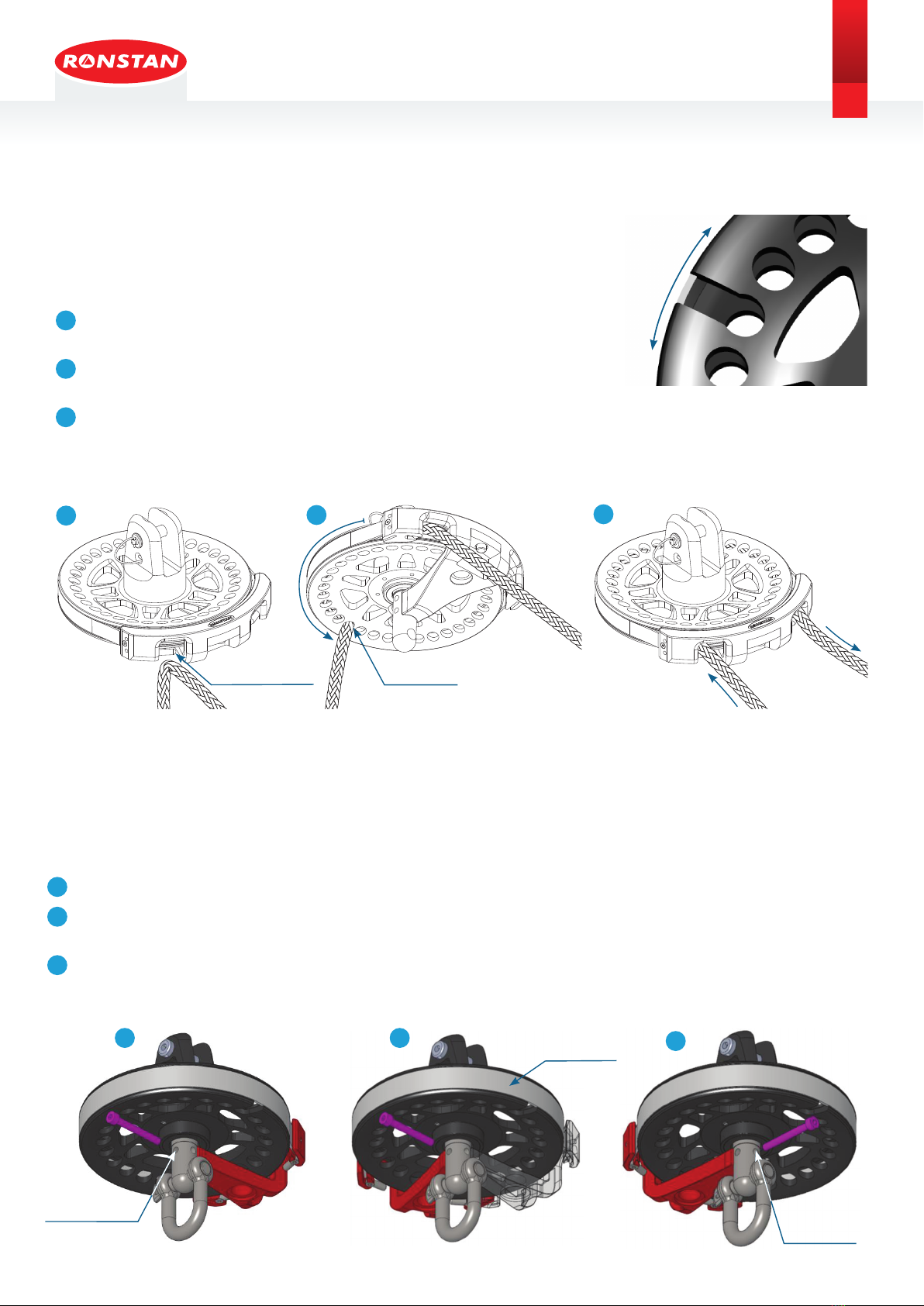

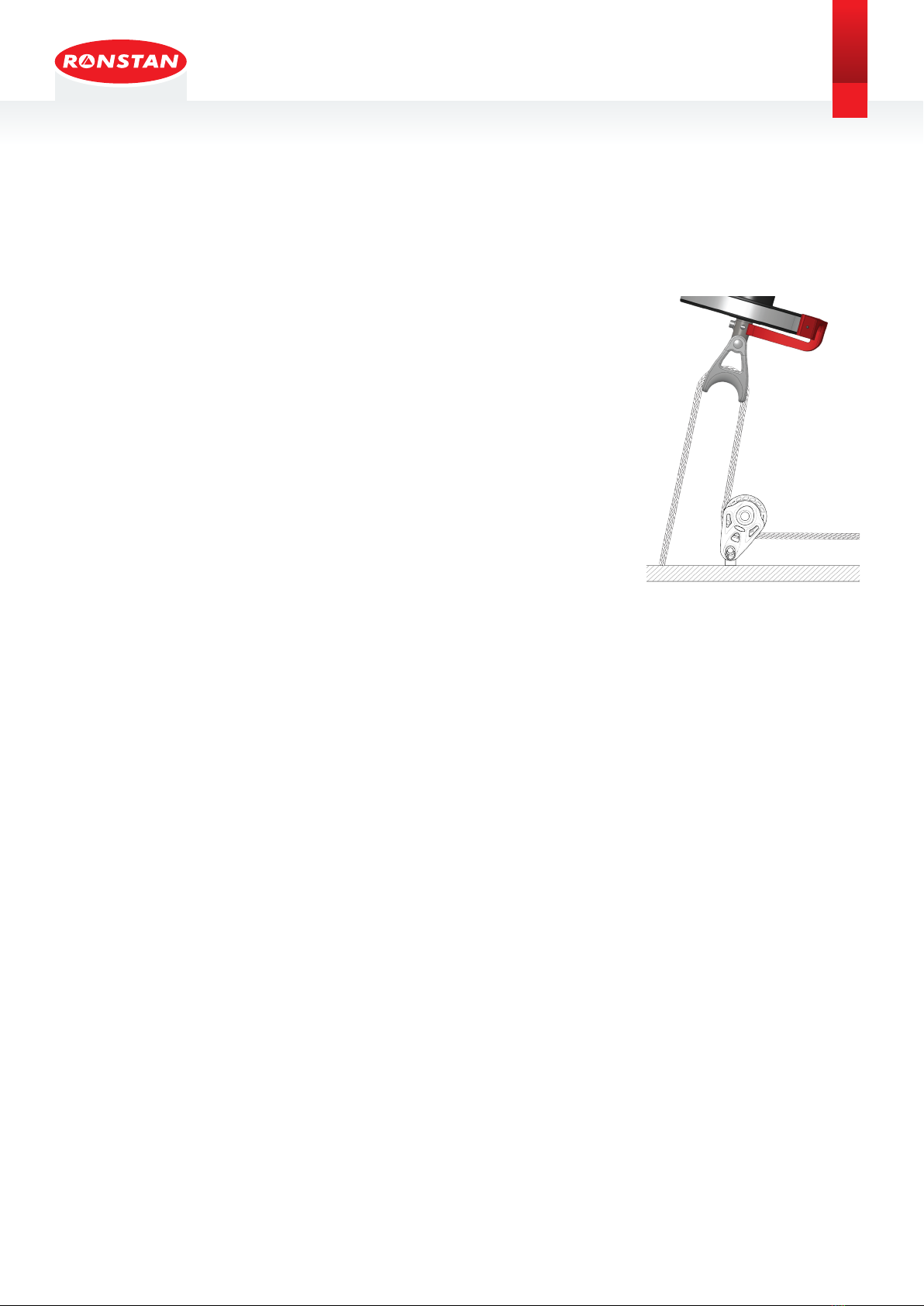

RS208030 – 2:1 Fairlead

Use in place of the shackle on the furler to provide a 2:1 purchase on the

furler attachment. The tack line is dead ended at the deck or end of the

bowsprit, runs up around the 2:1 fairlead, back down to a block, and back

along the deck to a rope clutch.

This conguration is a popular way of adjusting tension in the torsion

rope, and hence the lu of the sail.

RS208040 – Thimble

Used to terminate the torsion rope at both ends by wrapping the torsion rope around the thimble and then

either stitching it to itself, or splicing it. The thimble also has an additional hole suited to lashing the tack of

the sail to it. Lashing the sail to the thimble and not to the furler allows the torsion line and sail to be easily

removed from the furler and top swivel as required.

RS208050 – Shackle

Replacement shackles can be ordered to suit both the top swivel and the furler.

MAINTENANCE

•

Rinse regularly with fresh water to remove salt.

•

Apply Ronstan RF3000 Sailfast™ (or a similar silicon based lubricant) over the body and components to

enhance performance and prolong service life. (Do not use petro-chemical lubricants).

•

Periodically remove fasteners and re-apply Tef-Gel® (TG-10) to prevent corrosion.

•

Factory sealed bearings are maintenance free. Bearing and seal replacement can be arranged through your

local Ronstan re-seller.

•

Furlers have a three year warranty – refer to www.ronstan.com for terms and conditions.

Tef-Gel

®

is a registered trademark of Ultra Safety Systems Inc.

Sailfast

™

is a trademark of Ronstan International Pty. Ltd.

Typical 2:1 setup