RF25109 Series 20 BB OrbitBlock™ Lashing Head

User Instructions

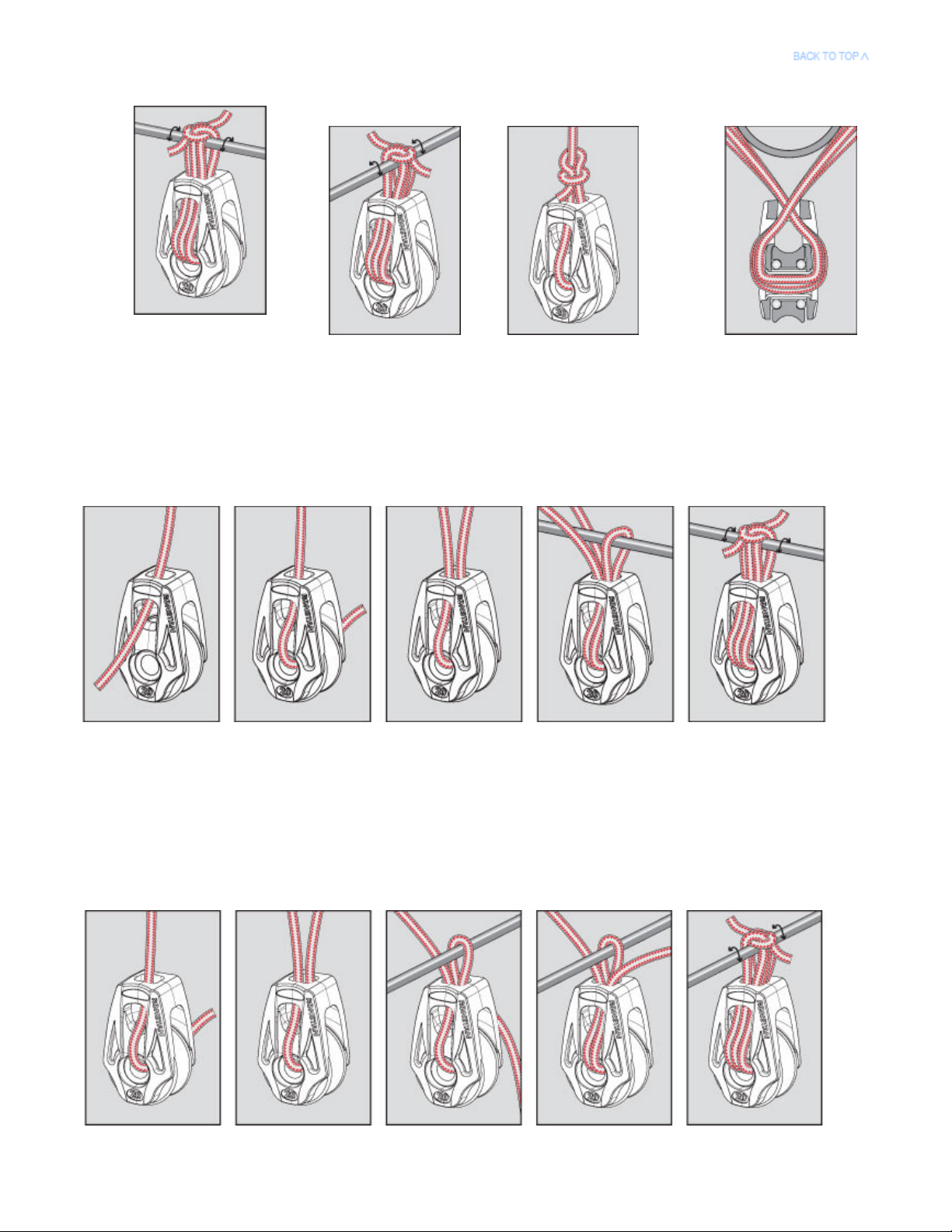

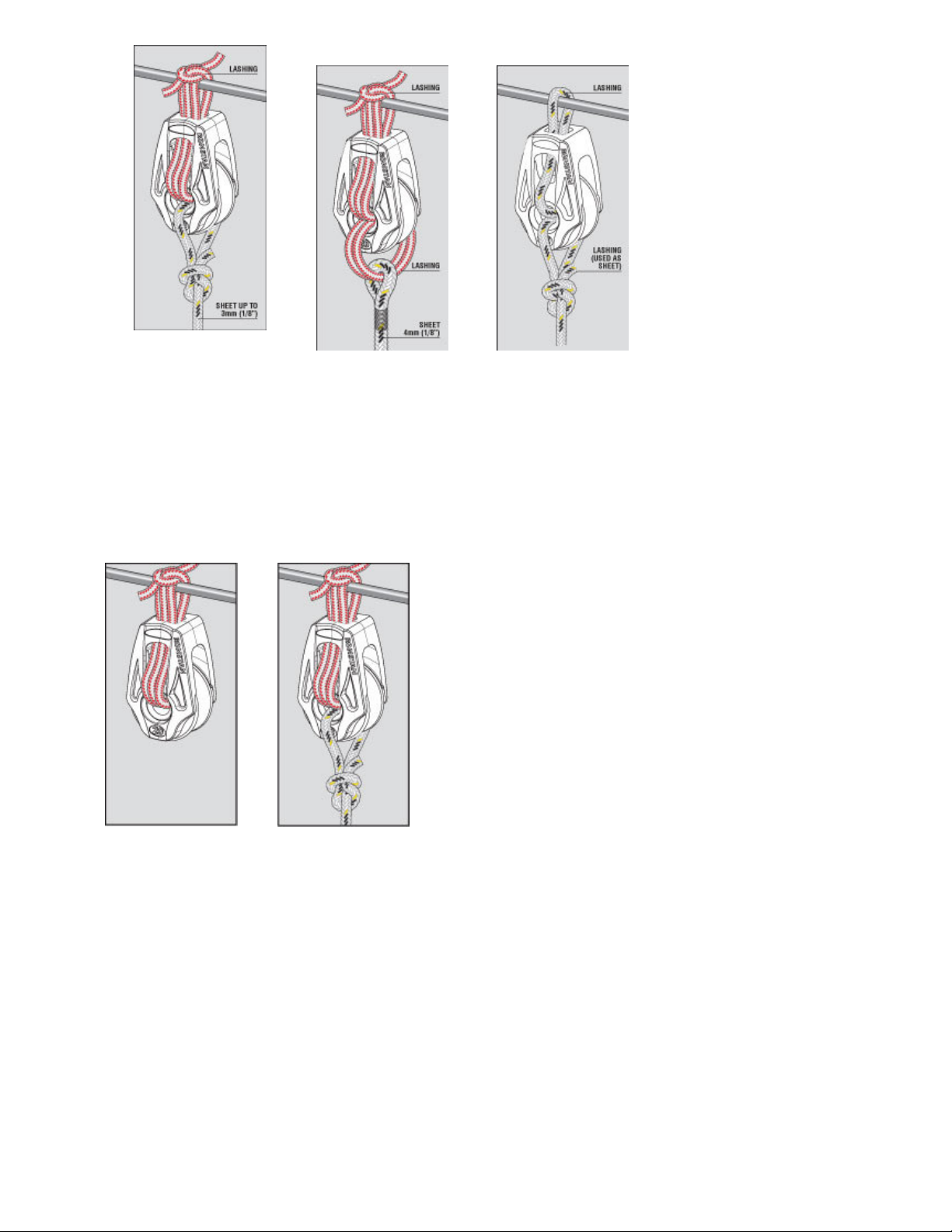

•1.0 Lashing Options

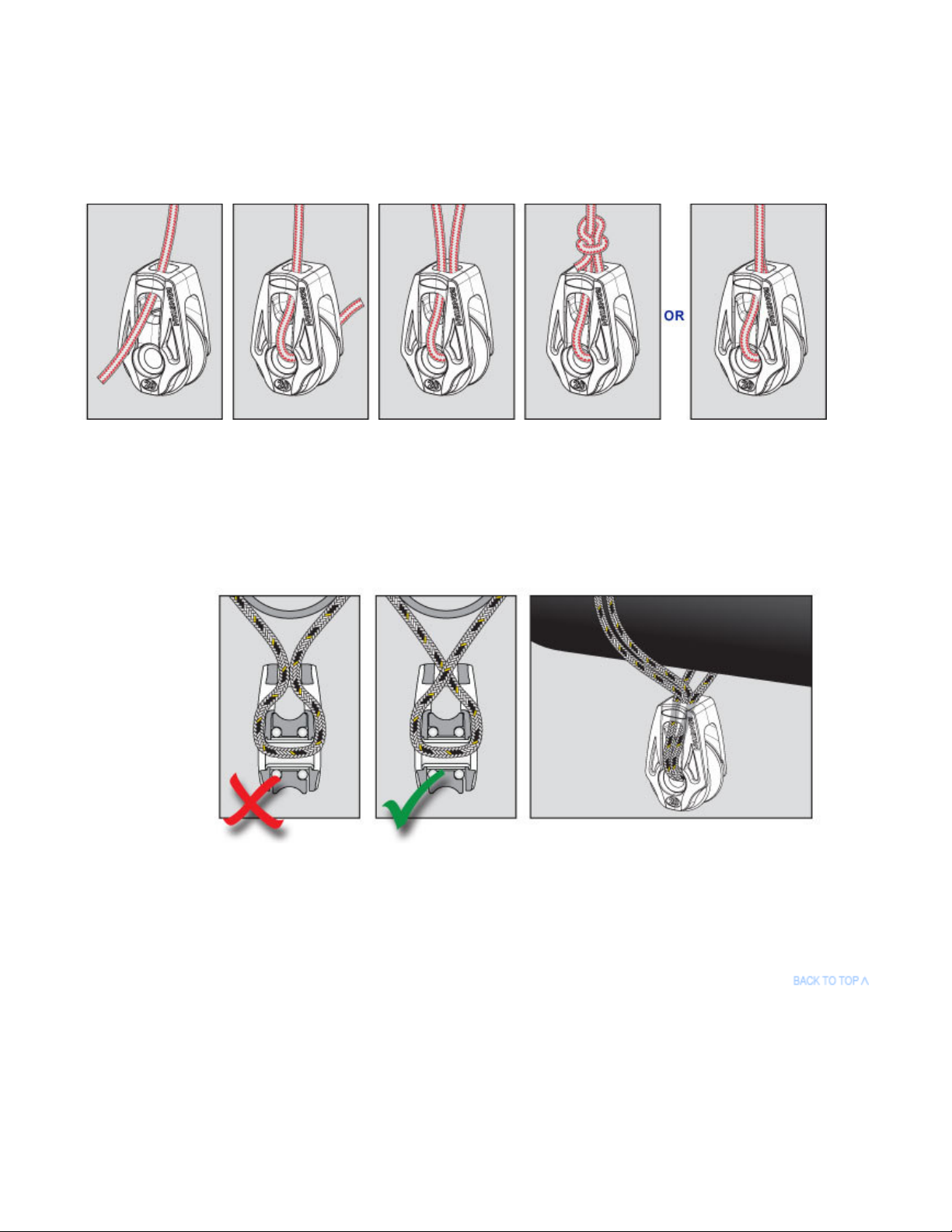

•2.0 Becket Options

•3.0 Care & Maintenance

•4.0 Definitions

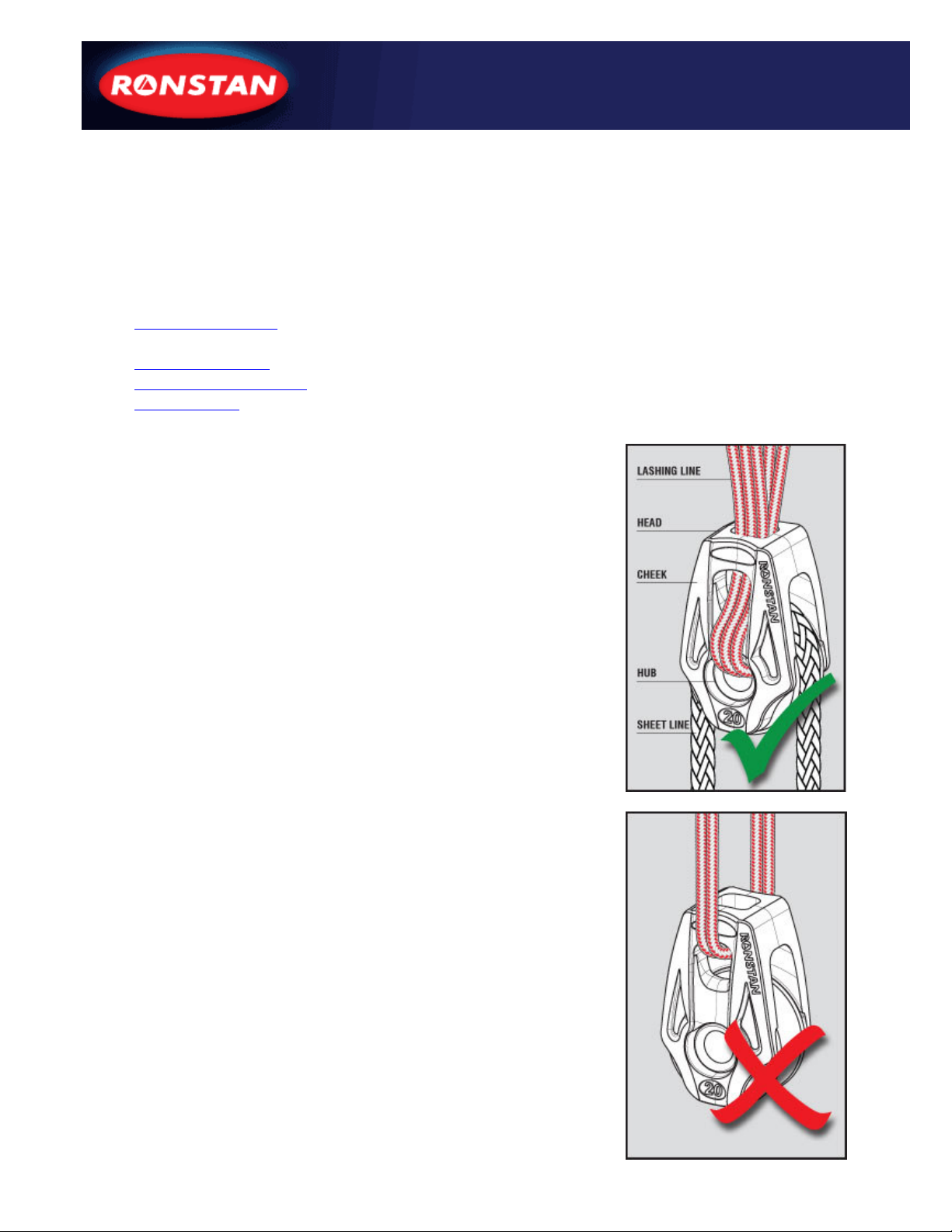

Ronstan BB Orbit Blocks™ feature a unique Lashing head. Building

on the latest trends in grand prix dinghy and ocean racing, it replaces

the steel head post and shackle arrangement of traditional blocks.

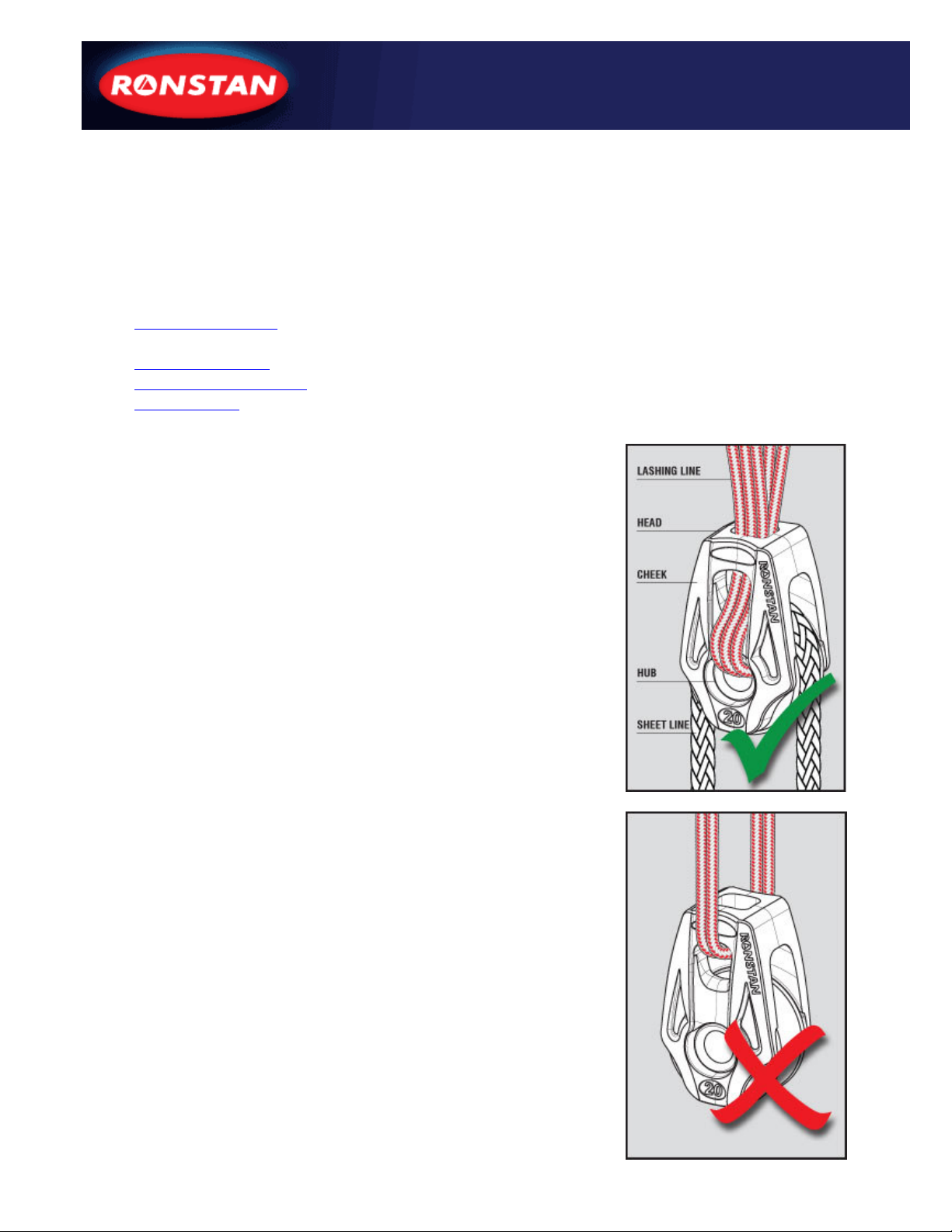

•IMPORTANT: In order to meet breaking loads this block must

be lashed with the lashing, strop or link passing through the

hub.

•The lashing must be passed down through the head, out through the

cheek, through the hub, back in through opposite cheek and back up

and out through the head. Repeat for lines, sizes that require more

than one strand to meet load rating.

•The Maximum Working Load and Breaking Load of the assembly

(Block + Lashing) is generally limited by the strength of the rope

and the joining method. Knots, splices, stitching, etc. will generally

have a lower Breaking Load than the rope itself. It is possible to use

up to 4mm (5/32”) lashing line for lashing the RF25109 running the

lashing around as a single strand, but a neater result with more

secure knotting can be achieved by using the smaller line size

provided(e.g. 1.7 - 2mm) wound through multiple times. The

RF25109 Series 20 Orbit Block™ is supplied with 750mm (30”) of

1.7mm (1/16”) diam. covered Dyneema® lashing line.

•For best results, the lashing must be attached to a mounting point

with a smooth, well rounded profile.

•Avoid attaching directly to fittings with sharp edges or rough

surfaces that may damage the lashing through abrasion or point

loading. For this situation use a shackle with a smooth surface

between the lashing and the fitting. Regularly inspect the lashing

for damage, if found replace immediately.