WRAPPA ANCHOR

‘WRAPPA’ ANCHOR

The WRAPPA (ATSL) has been tested and CE marked to BSEN

795: 1997 class B, (Temporary Anchor device.) Certified by

Approved

Body: SATRA, Safety Product Centre, SATRA House,

Rockingham Road, Kettering, Northants, NN16 9JH.

Identification No:0321

The WRAPPA is for single person use as an anchor point onto

vertical scaffold poles (standards). It is for use with a shock-

absorbing lanyard and full body fall-arrest harness.

SpanSet recommends that all PPE be personal issue.

Users must read and understand the information sheet and

instructions before using the GRIPPA.

FITTING INSTRUCTIONS

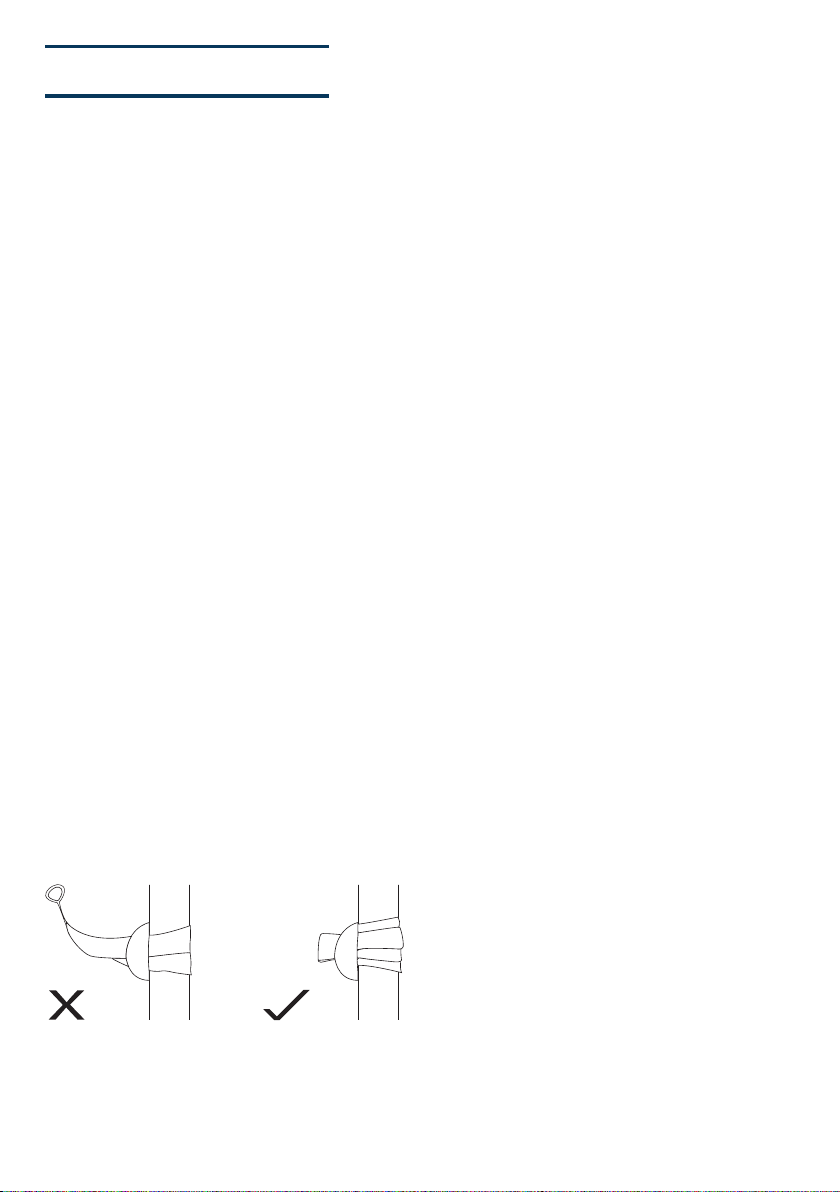

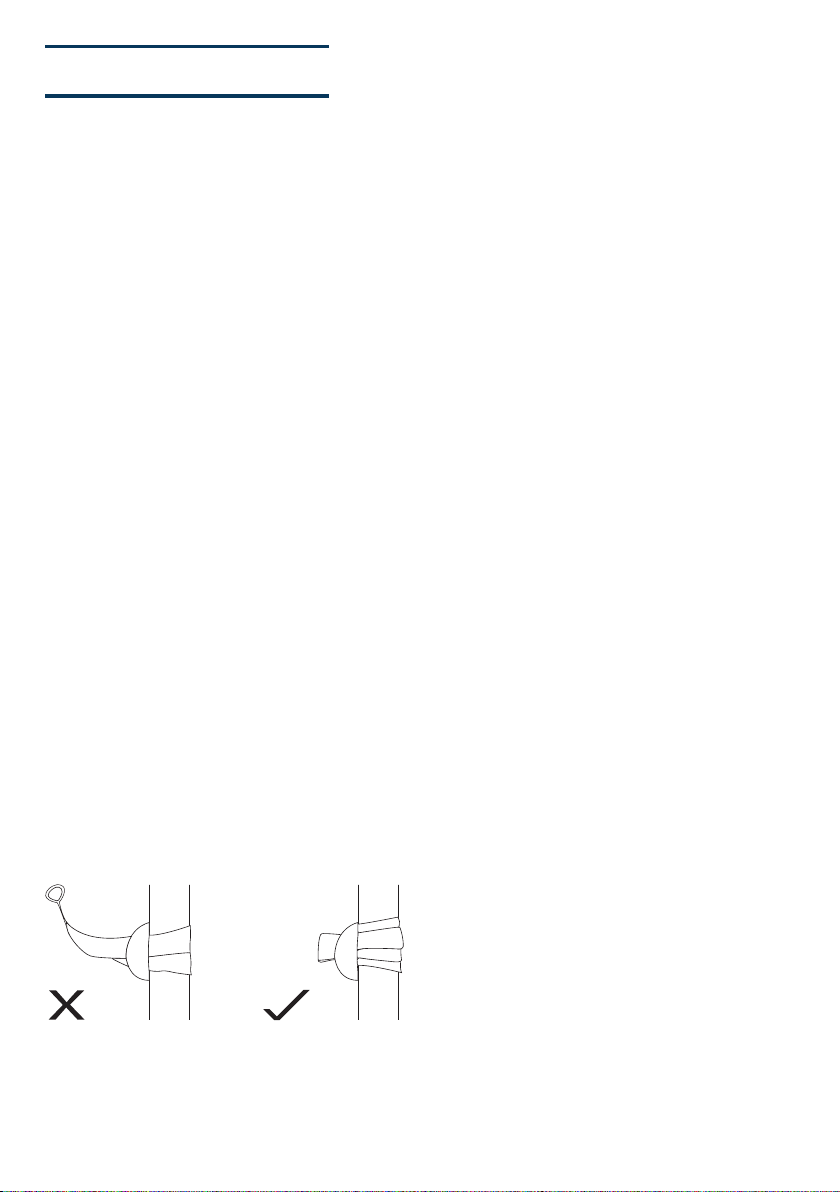

- Turn the sling inside itself TWICE around the pole and clip

into the choked end with the lanyard termination

(karabiner or scaffold-hook).

- The position of the WRAPPA is crucial for breaking

falls. Ensure enough height clearance is obtained below

the WRAPPA. The length of the fall and lanyard extension

should be taken into consideration to avoid all obstacles.

- Any items to be attached to the sling, for example

Karabiners, must be smooth and free from any burrs, or

sharp edges. Ensure all components of the system are

compatible.

- Always ensure your attachment point is suitably strong, at

least 10kN, and ensure attachment point is above the user.

- The sling strength is not significantly reduced when wet.

However in wet and icy conditions use additional caution,

as grip can be reduced.

- Never put the sling in direct contact with sharp edges.

WARNINGS

- Scaffold work a dangerous activity - learn how to use the

WRAPPA and make sure you understand how it works, if

in doubt contact SpanSet.

- Please note that you are personally responsible for

learning how to use the WRAPPA (Health and Safety at

Work Regulations) and taking the appropriate safety

measures, and that you accept total responsibility for the

use of this product.

- A rescue plan must be in place to deal with any

emergencies that arise during work.

- No alterations or repairs should be made to this

equipment.

- The WRAPPA should not be used anywhere other than on

vertical scaffold poles of 50mm diameter.

- Only attach a fall arrest lanyard certified to EN355 using a

full-body harness certified to EN361 to the WRAPPA using

connectors complying with EN362.

STORAGE AND PROTECTION

Keep these instructions, or a copy with the Adjustable Rope

All equipment should be stored in the following manner:

- To prevent contact with sharp objects.

- Away from harmful substances.

Keep in a cool, dry place free from direct sunlight.

INSPECTION AND EXAMINATION

Keep these instructions, or a copy with the attachment sling to

aid future inspection, and examination. The equipment must

be visually examined by a competent person when delivered

to site/works and thereafter at regular intervals (at least every

12 months), always thoroughly examine the sling before use.

Particular attention should be made to the following, and if

any damage found immediately remove the sling from service:

- Check the outer cover for cuts, or abrasion.

- Check for any fibres evident through outer cover.

Slings are susceptible to damage from acid rain, or alkali,

the slings strength could be seriously reduced by even short

exposure, and you probably will not be able to tell it has been

damaged. A sling you suspect to have been in contact with

acids, or alkali should immediately be withdrawn from service.

The attachment sling may be cleaned if required with mild

detergent in hand hot water, it should then be thoroughly

rinsed and allowed to dry naturally.

NOTE: REMEMBER; DO NOT ABUSE PPE. Your life

depends on your equipment and the way it has been

used in the past. A sling should be immediately removed

from service, and disposed of, after being subjected to

any fall, or if in any doubt about the sling condition.

Clip in here