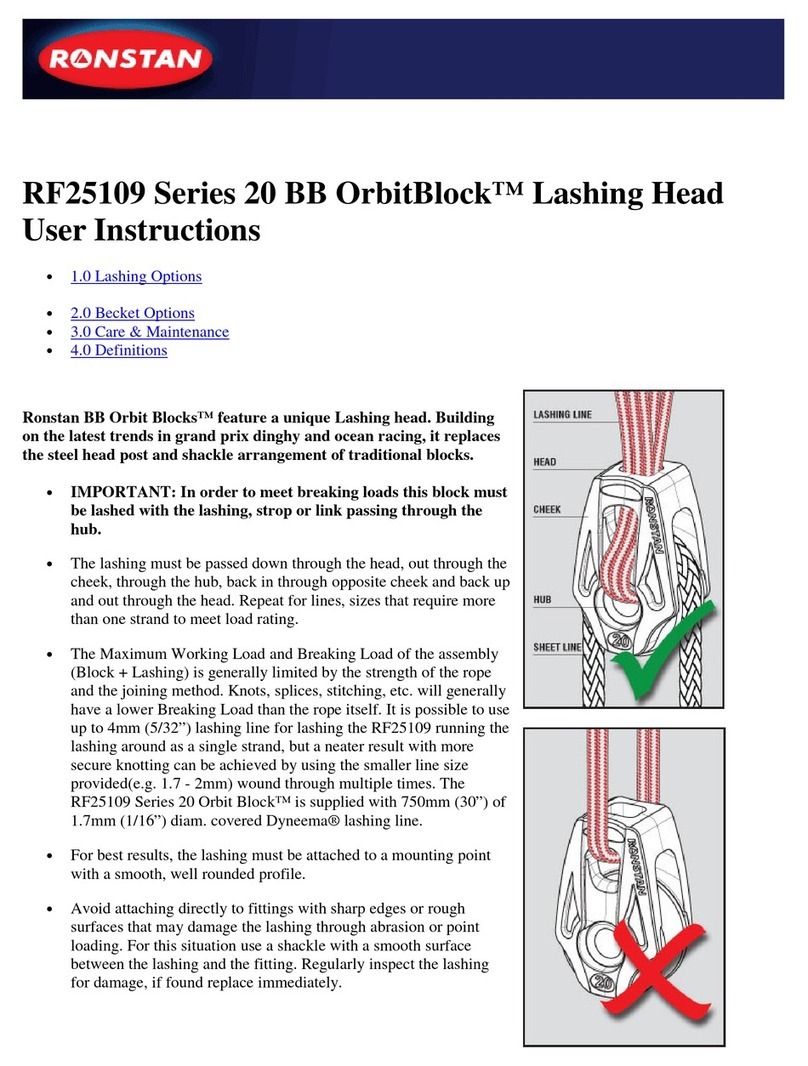

2.2.1 2.2.2 2.2.3 2.2.4 2.2.5

Pass the line down through the

head, out through the rear side

cheek and through the hub.

Loop under the bottom of the

block and again though the hub. Repeat step 2.2.2 if more than

one loop is required to meet the

desired breaking load. Pass line

in through the far side cheek and

back up through the head.

Finish lashing with appropriate

knot, splice or whipping. Attach

the sheet to the becket loops

using a bow line or splice.

If another loop is required to

meet breaking load, loop the

line around fixing point, pass it

back down through the head,

out through the near side

cheek, through the hub, back in

through the far side cheek and

back up through the head.

2.2 Lashing Used as Becket - for Sheets Line 4mm (5/32”) to 6mm (1/4”)

2.3 Single Line Used as Becket & Sheet Line - for Sheets up to 3mm (1/8”)

2.3.1 2.3.2 2.3.3

Pass the line in through a cheek,

up through the head, around the

fixing point, back down through

the head and out through the

opposite cheek.

Pass both ends through the hub

in opposite directions. Finish lashing with appropriate

knot, splice or whipping. If a

knot is used it must not be a

‘slip’ knot, and the knot must

be such that it pulls equally on

each line leading up to the hub.

A bowline is ideal. Note: the

breaking load of the installed

block is dependent on the

breaking load of the line; up

to a miximum B.L. of 550kg

(1210lb). Knots, splices,

stitching, etc. will generally have

a lower breaking load than the

rope itself.