7Double Seam Installation Manual

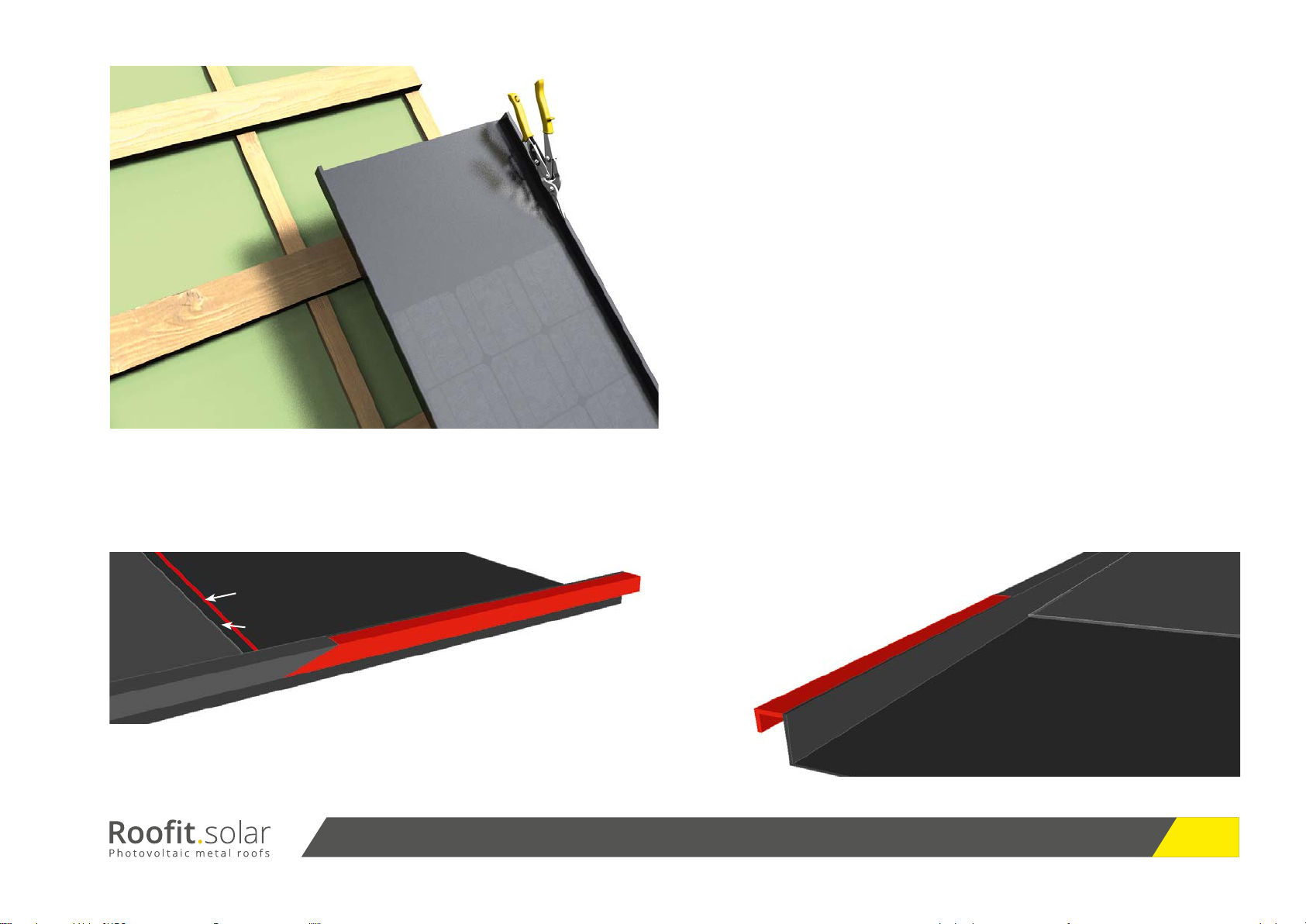

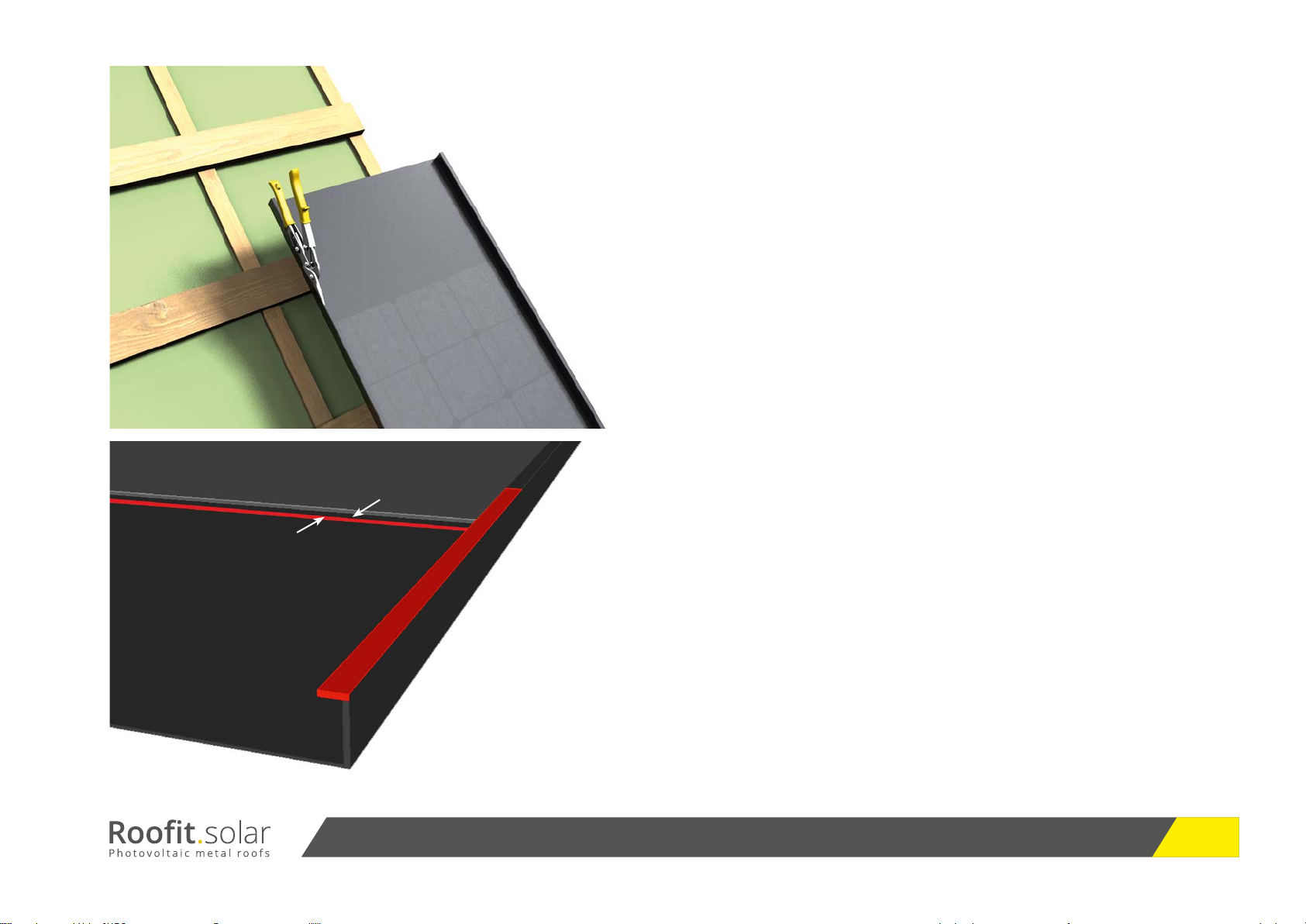

2. Cutting Locks / Edges:

Depending on the length of the roof, the distance of the overlap

(the point where one Root.solar panel joins another) may vary.

The overlapping area must be a minimum of 200 mm. Due to

thermal expansion, subsequent Root.solar panels which extend

to the overlapping area should be 3 mm away from the previ-

ous panel.

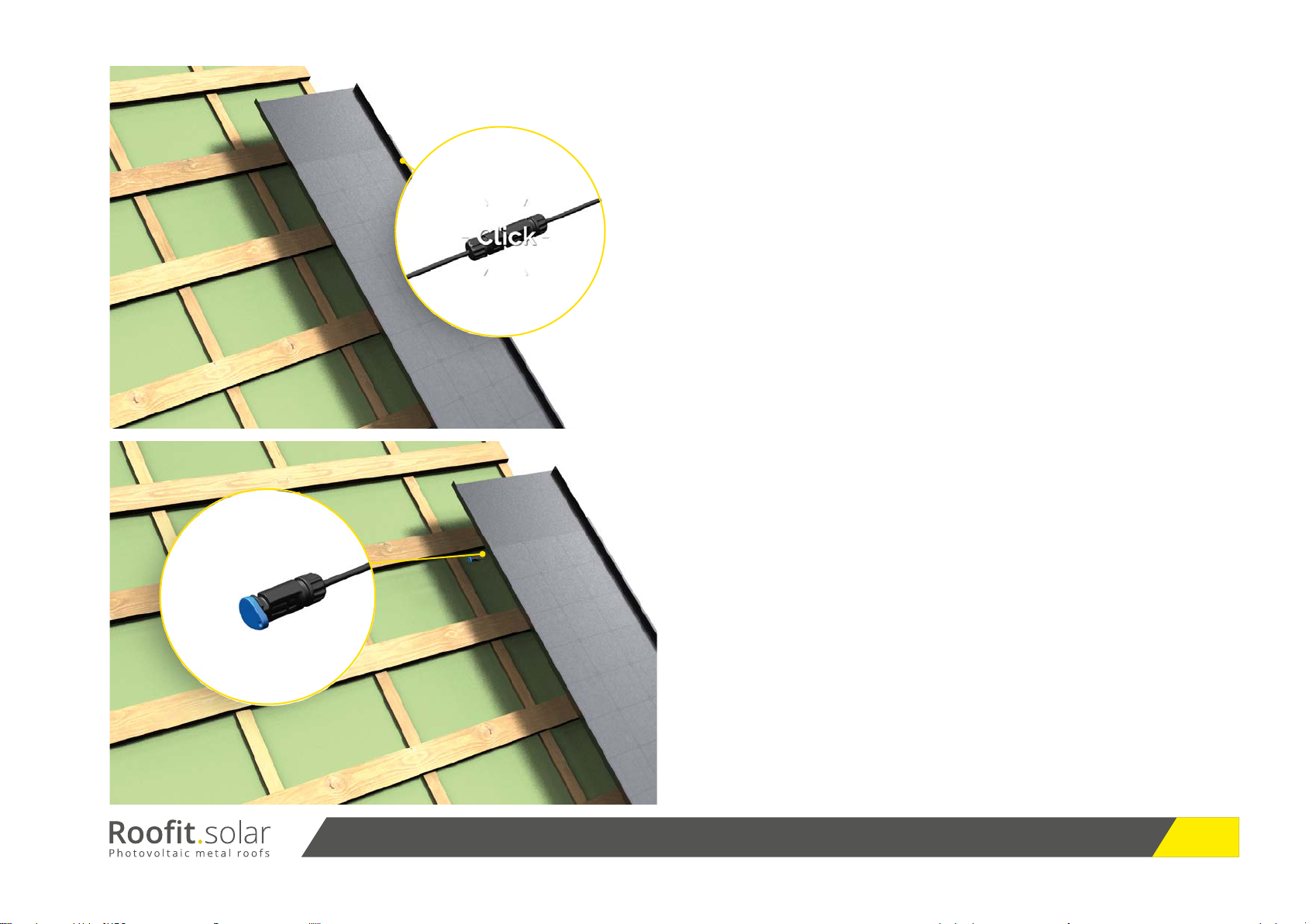

2.1 Cutting higher lock is shown accordingly in Figure 4, 4 a and

4 b. Starting from line where the Root.solar module overlaps with

the next one, the cut should start from outside of the lock with

the angle of approximately 30 degrees as it is shown in Figure 4 a,

till it reaches the edge. Then, the cut continues perpendicular to

module alignment until it reaches the end of upper part of the

lock. After that, the cut continues till the upper part of the lock is

completely cut out as it is shown in Figure 4 b.

Fig. 4

Fig. 4 a Fig. 4 b

Line for next

module

Active

PV Area

Overlapping Area

min. 3 mm

Overlapping Area

Active

PV Area

Please read Roofit.solar Safety Manual cerafully before initiating any Roofit.solar system installation.