INSTALLATION

RECEIVING:

Immediatelyupon receiving the crimping andbeadingmachine,checkitvery carefully for damage

orlossofparts in transit. Since all equipment is sold F.O.B.,theRoperWhitneyCompanyplant,

ourresponsibilityfor transit damage ceases when the transportation company signs the billof

ladingindicating that it has receivedall of the items listedon the bill of ladingin good condition.

Reportanyloss or damage to the delivering carrier promptly to insure proper handling of your

claim.

Question--DistributororRoperWhitney-- Shortages not appearing on the bill of lading or dis-

crepanciesbetweenequipmentreceivedandtheordershould be reported to Roper Whitney

Companyimmediately.

INSTALLATION -- (CAUTION!):

Besure beading machine is solid andreasonably level on all four pointsso there is no camber or

twistto the machine.

Ifmachineisshippedonapallet,be sure to remove from pallet and place directly on a bench.

Machinemustbesecurelyboltedtoabenchandbenchboltedtothefloor. Boltholes are provided

inbaseofmachine.

CLEANING:

Inspiteofprecautionstakeninpreparingthebeadingmachineforshipment,dirtandforeign

materialmay accumulate duringtransit,andcan cause damage unlessthoroughlycleaned. Itis

extremelyimportant to inspectandthoroughly clean offanydirtand foreign materialthatmayhave

accumulated. DONOTattempttoblowdirtout with an air hose as this may force some foreign

materialinto undesirable areas. Remove anyrust-proofingcompoundwithan acceptable solvent.

OPERATION AND ADJUSTMENT

CAUTION! Donotoperatebeadingmachinewithoutproperinstructions. Becomefamiliarwith

theintendedoperationbeforeusing. Machineto be operated by qualified personnel only.

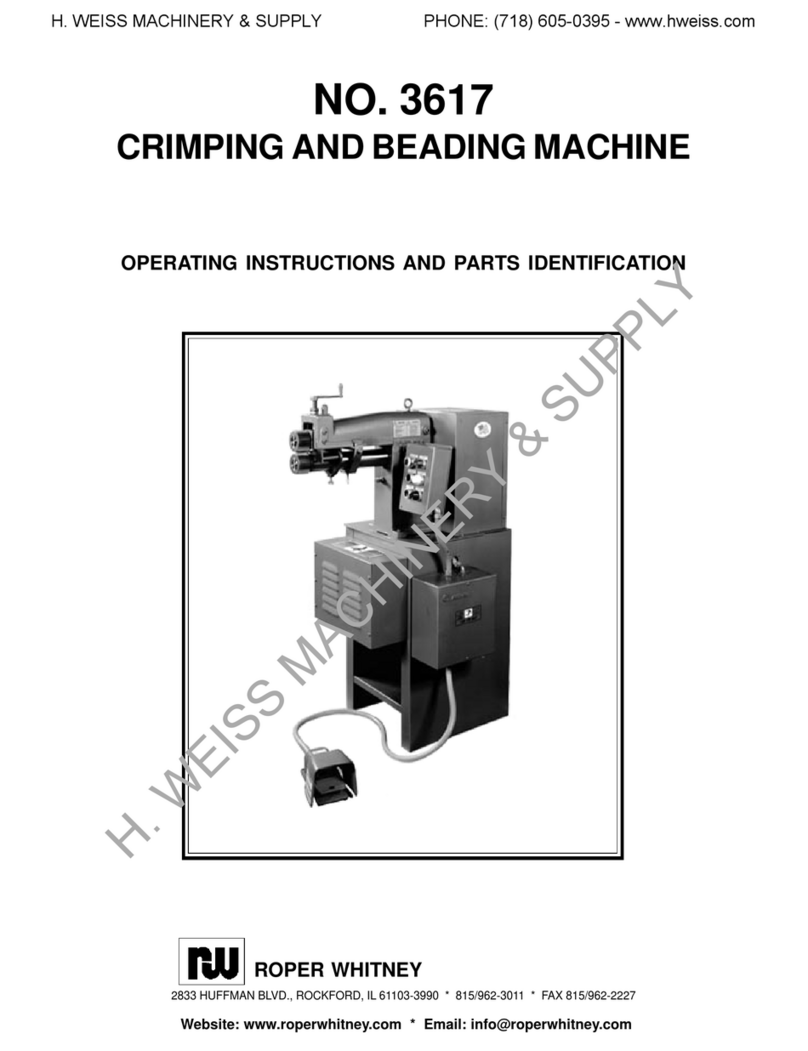

ThisPEXTObeading machine is intended for deep throat beading,crimpingand other roll opera-

tionson18gaugemaximummildsteelsheet material. The positioning gauge is adjustable within

it’s 12” range.

Rollsare secured totheshaftsby roll nutsandkeys. Thelower shaft horn adjustmentwillprovide

lateraladjustment for alignment of the rolls. An adjustable “saddle” bracketwillprovideadditional

supportfor the lower shaft horn when required. The pivotinguppershaftisspringloadedin the

openposition. Amountof the opening is controlled by the adjusting screw and crank screw lever.

- 3 -

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com