RoperWhitney-Model3617Crimping&BeadingMachineManual

12. Usesafety glassesandrequiredprotectivetools.

13. Keep work areas clean and in proper order.

14. Bealerttoallpotentialhazards. Notifyyour supervisor whenever you feel thereisahazard

involvingtheequipmentorthe performance ofyourjob.

BEFOREINSTALLINGTHISCRIMPINGAND BEADING MACHINE, READANDUNDERSTAND

THISMANUALANDSAFETYREQUIREMENTSFOR THE CONSTRUCTION, AND CAREOF

USEOFTHECRIMPINGANDBEADINGMACHINE.

INSTALLATION

Receiving:

Immediatelyuponreceivingthecrimpingandbeadingmachine,checkitvery carefully for damage

orlossofpartsin transit. Since all equipment is sold F.O.B., the Roper Whitney Companyplant,

ourresponsibilityfortransitdamageceaseswhenthetransportationcompanysignsthebillof

ladingindicating that it hasreceived all of the items listed onthe bill of ladingin good condition.

Reportanylossordamagetothedeliveringcarrierpromptlytoinsureproperhandlingofyour

claim.

Question-Distributor or Roper Whitney - Shortages notappearingon the bill of lading ordiscrep-

anciesbetweenequipmentreceivedandtheorder should be reported to Roper Whitney

Companyimmediately.

Leveling:

Besuremachine is solid and reasonablylevelon all four points sothereis no camber or twist to

themachine.

Ifmachineisshippedon a pallet, be sure to remove from palletandplacedirectlyon flooring.

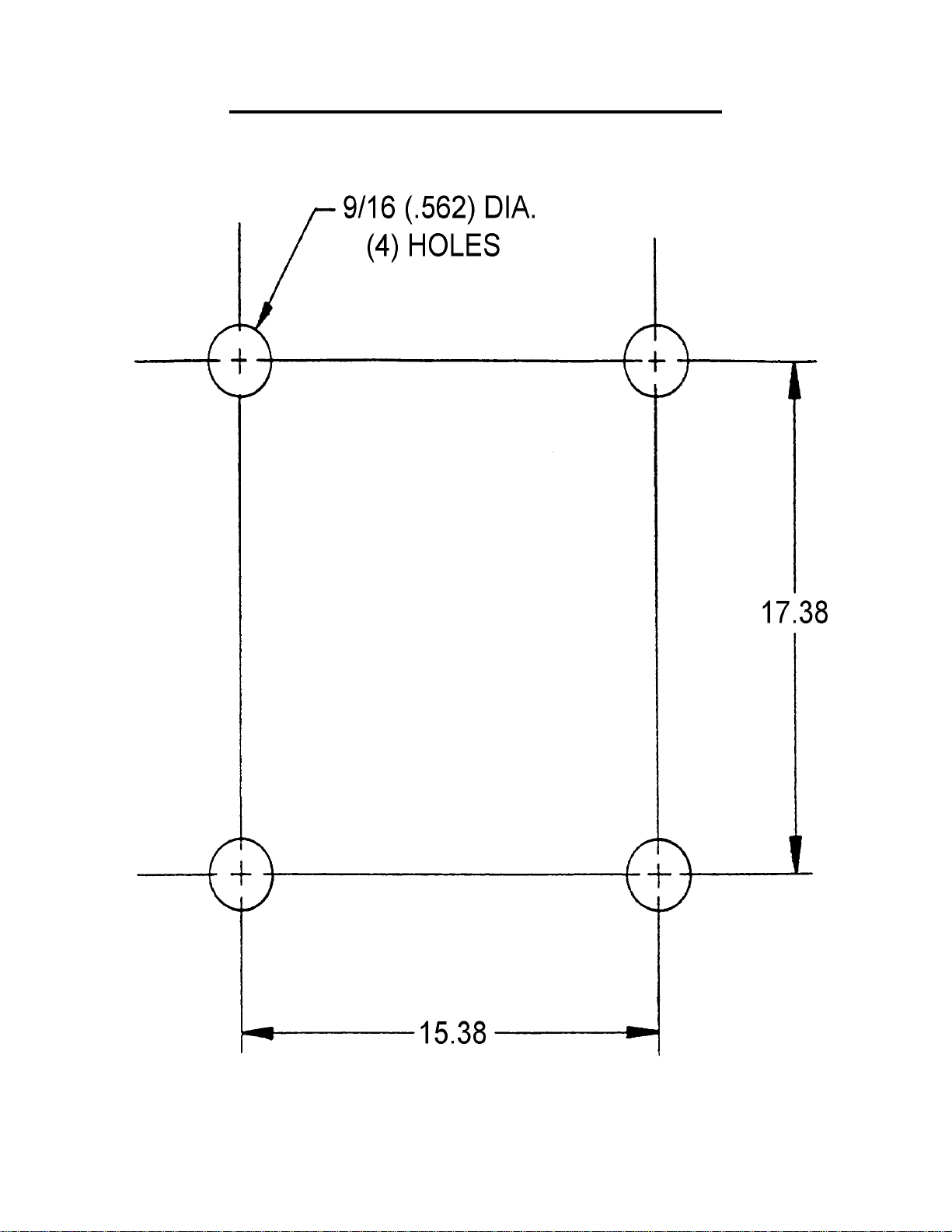

Machinemustbe securely bolted to floor. Bolt holes are provided inbaseof machine, and see

page5forboltmountingpattern.

Cleaning:

Inspiteofprecautionstakeninpreparingtheshearforshipment, dirt and foreign material may

accumulateonmachineandotherpartsduringtransit,andcancauseconsiderabledamage

unlessthoroughlycleaned. Itis extremelyimportanttoinspectandthoroughlyclean offanydirtand

foreignmaterialthatmayhaveaccumulated. DONOTattempttoblowdirtout with an air hose as

thismayforcesomeforeignmaterialintoundesirableareas. Removeanyrust-proofingcom-

poundwithanacceptable solvent.

-4-

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com