User Manual

2

Table of Contents

List of Figures ...................................................................................................................... 2

1. Brief Description ......................................................................................................... 3

1.1. Intended Use ............................................................................................................. 3

1.2. Function ..................................................................................................................... 3

1.3. Use ............................................................................................................................. 3

2. Assembly of the Tweezle O ......................................................................................... 3

2.1. Before Installation ..................................................................................................... 3

2.2. Visual and Functional Inspection ............................................................................... 4

2.3. Proper Mounting Methods (examples) ..................................................................... 4

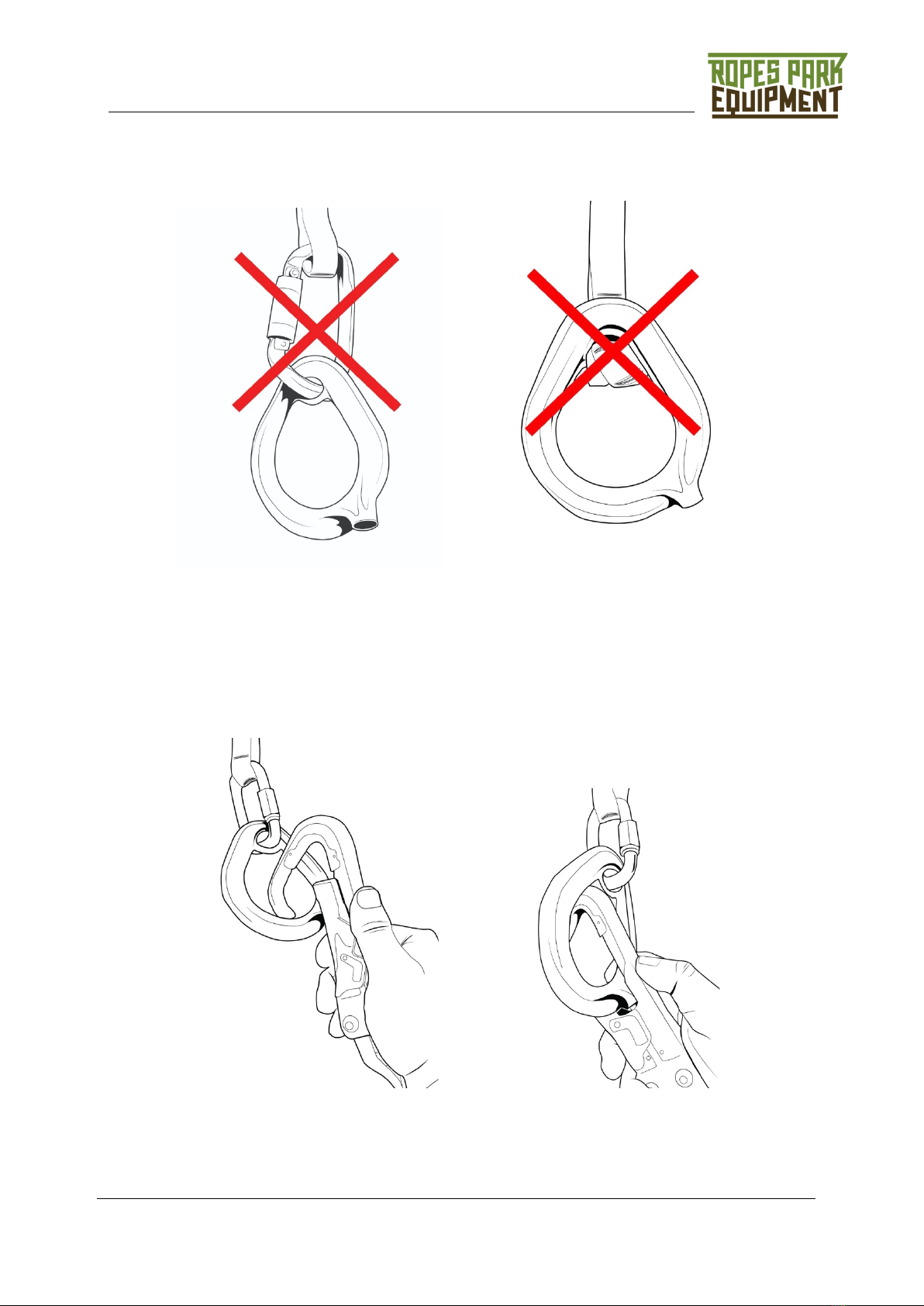

2.4. Improper Mounting Methods (examples) ................................................................. 5

3. Use of the Tweezle O ................................................................................................... 5

3.1. Use without shortcut ................................................................................................. 5

3.2. Use with shortcut ...................................................................................................... 6

4. Cleaning and Storage ................................................................................................... 8

4.1. Cleaning ..................................................................................................................... 8

4.2. Storage ....................................................................................................................... 8

5. Other Safety Principles ................................................................................................ 8

6. Supplemental Information .......................................................................................... 9

6.1. Conforming Standards ............................................................................................... 9

6.2. Declaration of conformity .......................................................................................... 9

6.3. Sales and Translations ............................................................................................... 9

6.4. Regular Checks ........................................................................................................... 9

6.5. Life of Product ........................................................................................................... 9

7. Annual Inspections by Qualified Individuals .............................................................. 10

7.1. Inspection Criteria ................................................................................................... 10

7.2. Inspection Procedures ............................................................................................. 10

8. Inspection Report Template ...................................................................................... 10

9. Product Markings and Labels ..................................................................................... 12

10. Your partner and direct contact for any questions ..................................................... 12

List of Figures

Figure 1: Tweezle O mounted with girth hitch on lanyard ............................................ 4

Figure 2: Tweezle O mounted with rated maillon ......................................................... 4

Figure 3: Tweezle O securely mounted on a trolley ...................................................... 4

Figure 4: DANGER: Tweezle O improperly mounted on carabiner ................................ 5

Figure 5: DANGER: Tweezle O not properly connected ................................................. 5

Figure 6: Clip the unlocked carabiner of the LockD Clips system onto the Tweezle O .. 5

Figure 7: Tweezle the unlocked carabiner to lock it on the Tweezle O ......................... 5