I

2) Foreword:

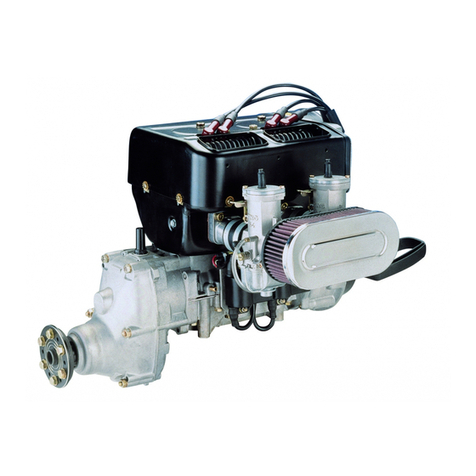

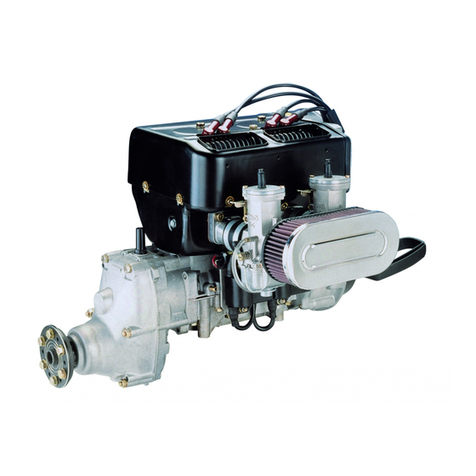

TheROTAXengineisanair-cooledz-strokeengine,

Carefuland

extensivelytested

design

andrugged

consEuction

aswell astheuse

of highqualityparrs

increasoreliabiliry and

durabiliry,Wirh proper

maintenanceandcareandwiththeuseofsuitablefuelandoil dreengine

should

give

yougoodservice

for manyyears.

TheROTAX designincorporatesthelatesttechnical

developments.In

orderto tate advantage

of

futue developmentswercseNerhedghrromake

modificationsintheROTAX design

withoutnorice.

NOTE:All fasrenersaremetricwiththeexceptioooftheinternal

thread

ofthe

p.T.

O_cankshaftwhich

is1/2

"narionalfineftread.Itisto

your

advantage

to

read

thismanual

carefullyforthe

ptotection

ofyour

engine.Theremaybesigrficant

differencesfrom

othettypes

offwocycle

engines

you

mayhaveworkedon.

Alwaysuse

genuine

ROTAX pafis.

I A Neue.r,raenginewirhoutproperloading,

e.g.corect propeller.

Refersection17.

Section

3

Fuelandoil:

Fuelcoltamination

isa

najorcauseofenginefailure.The

bestplace

toavoidcontamination

is

atthe

source.Once

inyorufuel

container',averyharzadouspotendal

edsts.

Use

aclean

safety

approved

storage

corltainer.

Filter all fuelenteringandleavingthiscontainer.

Do

nol

over- conlainer.allowforexparrsion.

WARNING: Gasolineisflan]mableandexplosive

undercertain

conditions.Alwaysperform

pioce-

dDresin awellventilatedarea.

Donot

smokeorirllow

openflames

orspaJksin tie vicillity.

Neve'raddfuel while engineisnuudDg.

Refertoteclmicaldata-TheengineisdesigdedtooperateafuelfiitI.yJith

2Eaoil. Beswetouse

ploductsof atleastthestandardshownin thetechnicfll

datasectioD.

Ifthe

engioeistobeusedinverted

(with

spark

plugspointing

down)

selectalubricant

whichfeatures

lowcarbondeposits.Oilresidueteidsrodrain

to

lowpoints,

i.e.

spark

plug

cavities.

If rhisresidue

fails to burn cleanduring normad

operation,

plug tbuling will occur,possible

prc-ignirion also.

Manufacturersof suitablelubricanrswill guariurtee

theirproducts

in writing.

Do notusefuel whichhasbeenstorcdfor alongperiod

of time.

Do flotleavefuel exposedto sunlightin translucentcontaine$.

1)

A