70 SERIES DRIVE HEAD ASSEMBLY PARTS LIST

8

Item Part No. Qty Description

1A* 8784 1 Grease Fitting

1B* 130320 1 Crankpin Cover Bolt

2* 25238 1 Crankpin Cover

3* 6408 1 Lock Wire - 36” (91 cm)

4* 7554 8 5/8” x 2-1/2” NF Cap Screw DH

5* 25237 1 Clamping Sleeve

6* – – Head End Plate (part of box frame)

7* 157790 1 Crankpin

8* 22845 1 Felt Seal – 5/16” sq. x 32-13/16”

9* 317100 1 70 Gear / DA / S Crankpin Bearing Housing

10* 10934 1 Crankpin Bearing

11* 157786 1 Snap Ring

— — — —

13* 11628 1 Crankpin Bearing Spacer

14* 11629 1 Crankpin Bearing Spacer Lock

15* 2362 1 Screw, FH – 5/16” NF x 3/4” Lg.

15A* 92788 1 Baffle Plate

16* 11521 1 Crankpin Bearing Gasket

17 11490 1 Crankshaft Assembly

18* 120630 12 5/8” conical lock washer

19* 6437 12 5/8” x 1-1/2” NF HH Cap Screw DH

20* 6408 1 Lock Wire – 72”

21 11687 1 Crankshaft Key

22* 98838 1 3/8” x 7/8” NC Socket Head Screw

23 11649 1 Bearing

25 25225 1 Major Balance Weight Sleeve

26 11627 1 Oil Baffle

27 3600 8 3/8” Internal Tooth Lock Washer

28 6408 1 Lock Wire – 48”

29 9008 8 3/8”x 1” NF HH Cap Screw DH

— — — —

31 2637 8 5/8”x 2-1/2” NF HH Cap Screw

32 120630 8 5/8” Conical Washer

33 120194 1 Drive Head Cover Assembly

34 2637 4 5/8”x 2-1/2” NF HH Cap Screw

35 27346 2 Machined Lift Yoke

37 75758 1 Gasket

38 25226 1 Major Balance Weight

39 25227 1 Major Balance Weight Flange

40 5941 6 3/4” Internal Tooth Lock Washer

41 12249 6 3/4”x 2-1/4” NF HH Cap Screw DH

42 6408 1 Lock Wire – 36”

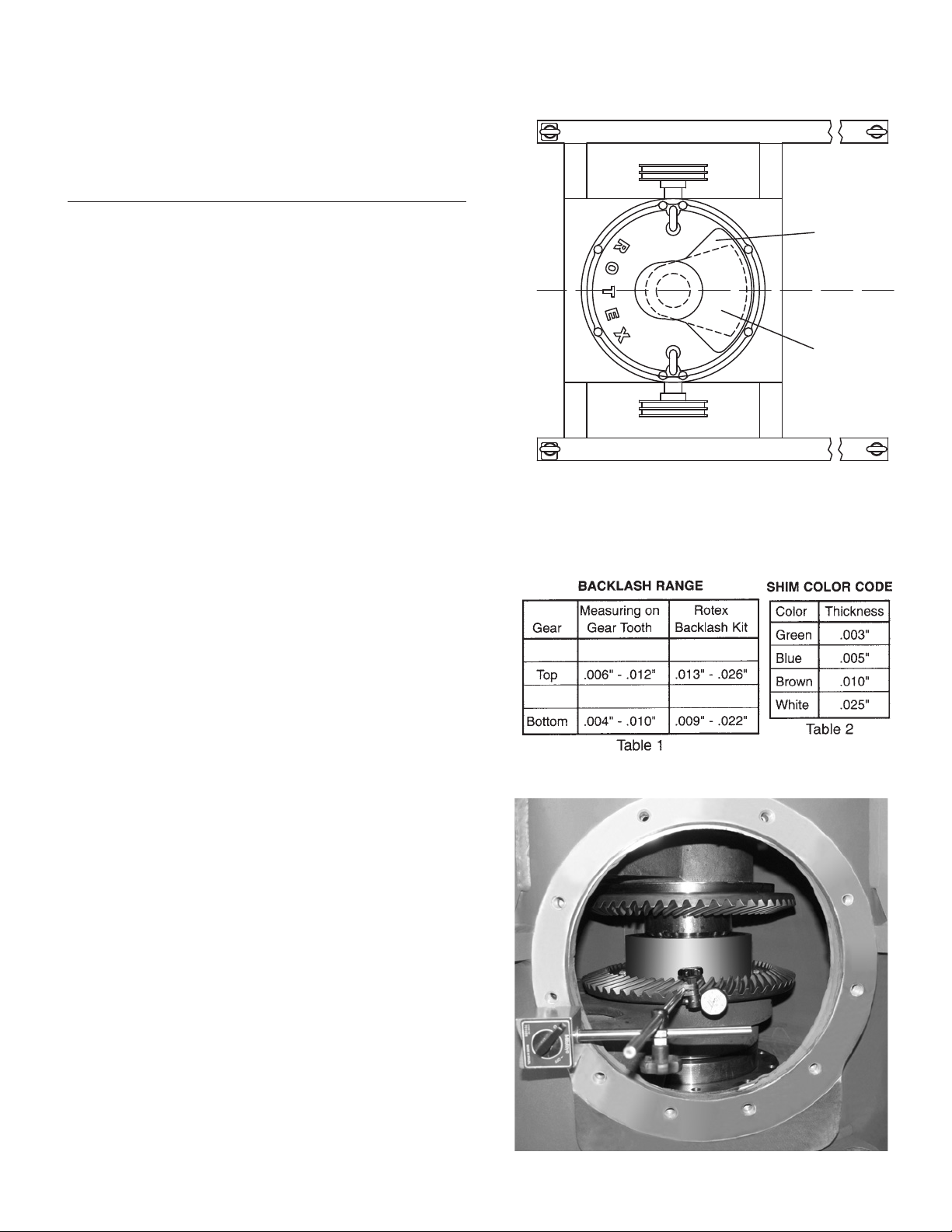

43** 11441 1 Spiral Bevel Ring Gear

44 4038 24 1/2” Internal Tooth Lock Washer

45 7694 24 1/ 2”x 1-1/4” NF HH Cap Screw DH

46 6408 1 Lock Wire - 36"

47 11405 1 Bearing

48** 11441 1 Spiral Bevel Ring Gear

49 25228 1 Minor Balance Weight

50 11546 1 Minor Balance Weight Spacer

51 11648 1 Bearing

52 11544 1 Lower Bearing Spacer

53 10934 1 Bearing

54 11618 1 Lower Bearing Support Collar

55 79080 1 Shim Set (Shims as Required)

56 11556 1 Drive Flange – Oil Pump

57 161873 3 7/8” Conical Washer

58 12247 3 7/8”x 2-1/2” NF HH Cap Screw DH

59 6408 1 Lock Wire – 12”

60 25230 1 Lower Bearing Rest

61 32684 1 Spring Pin (Roll Pin)

Item Part No. Qty Description

62 27520 1 Pump Housing Cover

63 24015 2 Truarc Snap Ring #5108-62

64 34159 1 Inner Gerotor

65 34160 1 Outer Gerotor

66 34161 1 Eccentric Ring 24014 Assembly

67 34162 1 Spring

68 34163 1 Friction Plug

69 24017 1 5/32”dia. x 9/16” long Drill Rod

70 24011 1 Pump Shaft Assembly

71 24016 1 Woodruff Key #405

72 2911 3 3/8”x 1-1/4” NF HH Cap Screw

73 27519 1 Pump Housing Body

74 4038 4 1/2” Internal Tooth Lock Washer

75 6426 4 1/2”x 1-1/2” NF HH Cap Screw

76 6408 1 Lock Wire – 12”

77 11766 1 Drive Housing Assembly

78 120630 10 5/8” Conical Lock Washer

79 6437 10 5/8”x 1-1/2” NF HH Cap Screw DH

80 8990 1 1-1/4”NPT Pipe Plug

81 6408 2 Lock Wire – 36”

82 2471 1 1/2” Pipe Plug

83 11620 1 Gasket

84 11539 1 Pump Sump Assembly

85 15233 10 1/2” Conical Lock Washer

86 2915 10 1/2”x 1-1 /4” NF HH Cap Screw

87 2471 2 1/2” Pipe Plug

88 10321 1 3/8” x 2-1/2” NF HH Cap Screw

89 26858 1 3/8” Flat Washer - SS

90 12109 1 Gasket for Clamp Bolt

91 12100 1 Oil Sight Tube Cap

92 12108 1 Oil Sight Tube Gasket

93 12110 1 Oil Sight Tube – 1-11/16”long

94 12108 1 Oil Sight Tube Gasket

95 347644 1 Inspection Plate Weldment

96 6090 1 Gasket

97 2915 10 1/2” x 1-1/4” NF HH Cap Screw

98 15233 10 1/2” Conical Lock Washer

99 11647 1 Bearing

100 12147 1 Lock Washer W12

101 12146 1 Lock Nut N12

102 11518 1 Pinion Shaft Housing Cap

103 12246 1 Felt Seal

104 15233 5 1/2” Conical Lock Washer

105 7694 5 1/2” x 1-1/4” NF HH Cap Screw DH

106 6408 1 Lock Wire – 12”

107 6090 1 Gasket

108 25231 1 Oil Seal Cap Casting

109 159233 10 1/2” Conical Washer

110 2915 10 1/2” x 1-1/4” NF HH Cap Screw

111* 50600 1 Bushing SF 2-1/4” Dia.

112* 52672 1 Rotex Sheave 2CQ160

113 6408 1 Lock Wire – 12”

114 6437 3 5/8” x 1-1/2” NF HH Cap Screw DH

115 170286 3 5/8” Conical Serrated Lock Washer

116 8625 1 Clamp Plate

117** 11440 1 Pinion Gear

118 11647 1 Bearing

119 12145 1 Pinion Shaft Key

120 11519 1 Pinion Shaft

121 12148 1 Pinion Shaft Key

122 79081 1 Shim Set (Shims as Req'd)

123 25229 1 Pinion Shaft Housing

124 120630 7 5/8” Conical Lock Washer

125 6429 7 5/8” x 1-3/4” NF Cap Screw DH

126 6408 1 Lock Wire – 36”

127 347640 1 1” NPT Street Elbow

128 347641 1 1” NPT Breather Vent

The following items may

be ordered separately or

as a complete Crankpin

Bearing Assembly 317101

Oil Pump Assembly 24008

*These items are not part of the drive head assembly and must be ordered separately.

**Gears are supplied only in matched sets.