1. TECHNICAL SPECIFICATIONS OF THE DEVICE

1.1. GENERAL

Rôtisserie range " Grandes Flammes" gas powered with electrical power of 230V + earth.

The device is for professional use and should be used by qualified personnel.

Before starting any operation, please see these instructions. Carefully keep available near the

rotisserie.

The upgrading of premises are at users expense.

Every cooking appliance generates heat and particles of fat.

Theunitshouldbeinstalledinaccordancewithinnorm's andregulationsinforceinawell-ventilated

area. With sufficient mechanical extraction and fire prevention. Would recommend that you call

uponaqualifiedcompanyfortheworktobedoneaccordingtothelocalnorm's extraction,gas

connection, building work.

We recommend that you call upon a qualified installer for the connection of the unit to the

gas and electrical supplies.

Interventions on the electrical parts must be performed by qualified personnel accordance with the

standards.

The company is not liable for damages if:

•improper use of the device

•non-compliance with standards

•incorrect installation

•non compliance with guidance on maintenance

•unauthorized modification

•installation of non-original spare parts

•installation and use of the rotisserie different than those provided by the mnufacturer

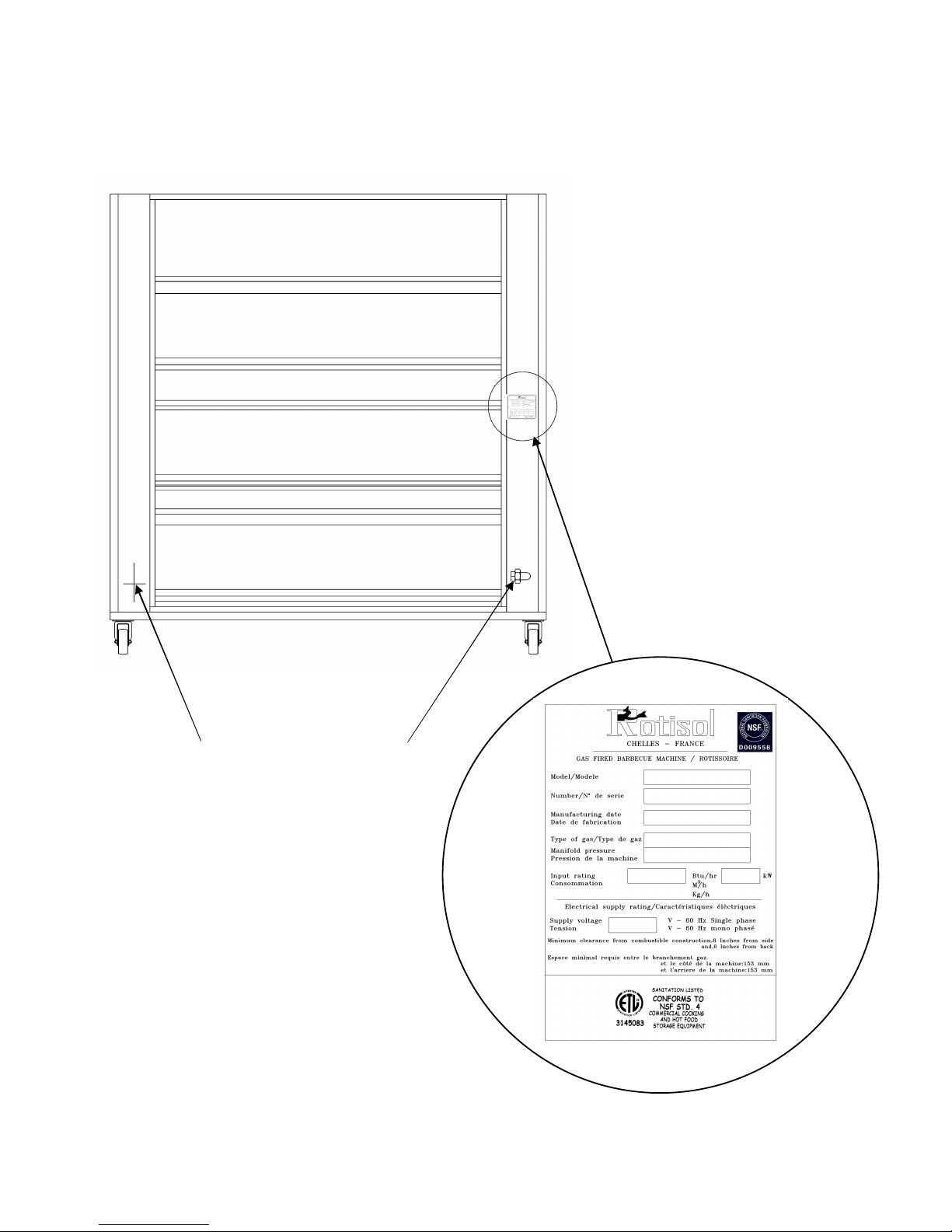

The plate is located on the back right in the middle of the amount.

1.2. TRADEMARK, MODEL, REFERENCE

Rôtissoires ROTISOL, model « GRANDES FLAMMES MILLENIUM », référence:

1675.8G, 1375.12G, 1375.8G, 1375.6G, 1375.5G, 1375.4G, 1375.2G, 975.8G, 975.6G, 975.5G,

975.4G et 975.2G.

All this information are the property of Rotisol.

Reproduction partial or in totality are prohibited without authority prior written of company Rotisol.

0,322014011606251025975.4G

0,43019516457001025975.6G

0,5530190116062514251375.5G

0,6445300164562514251375.8G

0,630320161070014451375.12G

0,645300164570014251375.6G

0,2910708006251025975.2G

0,352014011606251025975.5G

0,443019516456251025975.8G

0,491510080062514251375.2G

0,5230190116062514251375.4G

0,6451350164562517251675.8G

Electrical power

(kw)

Gas

power (kw)

weight

(kg)

Height

(mm)

depth

(mm)

Lenght

(mm)

Référence