Keeping the World Flowing

9

10.0 Installation on Valve

Before proceeding, read and understand the Health and

Safety information.

Note: The valve should be properly secured prior to

performing the following operations according to

instructions provided by the Valve Manufacturer.

Prior to performing any operations check the

operating drawings and TAG numbers.

Consult Rotork Fluid Systems for any additional information.

10.1 Preliminary Actions

Verify the Hazardous Area classification of the

actuator is compatible with the plant zoning. Refer to

actuator nameplate.

•

The centreline of the cylinder is usually aligned to the

centreline of the associated pipe work

•

Ensure all fasteners are adequately tightened to avoid

loosening during operation, taking into account the

vibrations induced by the dynamics of the pipeline

•

Piping used to provide power to the actuator must be

free from contaminants and debris. Ensure tubing runs

are adequately fastened and supported to minimize

repetitive stress induced by the dynamics of the pipeline.

Ensure there are no leaks from any gas connections.

Tighten as required

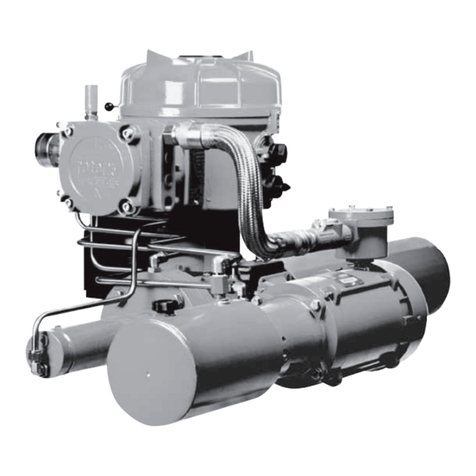

10.2 Instructions

Actuator to valve attachment can be performed by:

•

Mounting directly using the actuator housing bottom

flange drilling

•

Using an adapter and a coupling joint between the

actuator and the valve

Actuator bottom flange drilling is in accordance to ISO 5211

(DIN 3337) standard.

Fig 10.1 Actuator bottom connections

Each pinion, as standard, is provided with a female key ISO

5211 double square, allowing direct mating to the valve stem,

or coupling.

Optional valve interfaces are ISO 5211 single square parallel,

ISO 5211 single square diagonal and double D.

The assembly position of the actuator must be in accordance

with the actuator design, plant requirements and the valve

model. In order to assemble the actuator onto the valve,

proceed as follows:

•

Verify the coupling dimensions of the valve flange and

stem; they must meet the actuator coupling dimensions

(refer to PUB110-001 for metric and PUB110-002 for

imperial)

•

Actuator is supplied in the fail position (for single-acting).

Set the valve in the right position according to the

actuator fail position. Check the position of the actuator

by means of the position indicator on the body or on the

limit switch box (if present)

•

Clean the coupling flange of the valve and remove

anything that might prevent adherence to the actuator

flange. Grease shall be completely removed

•

Inspect, clean and apply grease on the coupling hole

(valve side of coupling joint)

•

Lubricate the valve stem with oil or grease, to facilitate

assembling

Lift the actuator according to instructions in section 7.0.

•

If possible, place the valve stem in a vertical position

to facilitate assembly – in this case the actuator must

be lifted while the coupling flange is kept in the

horizontal position

•

If a direct mounting is applied, insert the valve stem

directly into the actuator pinion

•

If the assembly uses an adapter and a coupling joint,

assemble the coupling joint onto the valve stem before

proceeding with mounting of the actuator

•

Do not exert any force while lowering the actuator

onto the valve

Installation must be performed by qualified personnel.

Hands must be kept away from the coupling area.

•

Fix the actuator to the valve by means of threaded

connections (bolts, stud bolts and nuts)

•

Tighten bolts or nuts of the connecting stud bolts to the

correct torque, in accordance with the size and material

characteristics of the bolts installed by the Customer,

please refer to the Tightening Torque Chart, section 6.3

Support the actuator until fully installed and fixing

bolts are correctly tightened.

Attention: Do not pressurize the actuator/

valve adapter.

A4 US

US

A4

US

A4

A4 US