GENERAL INFORMATION

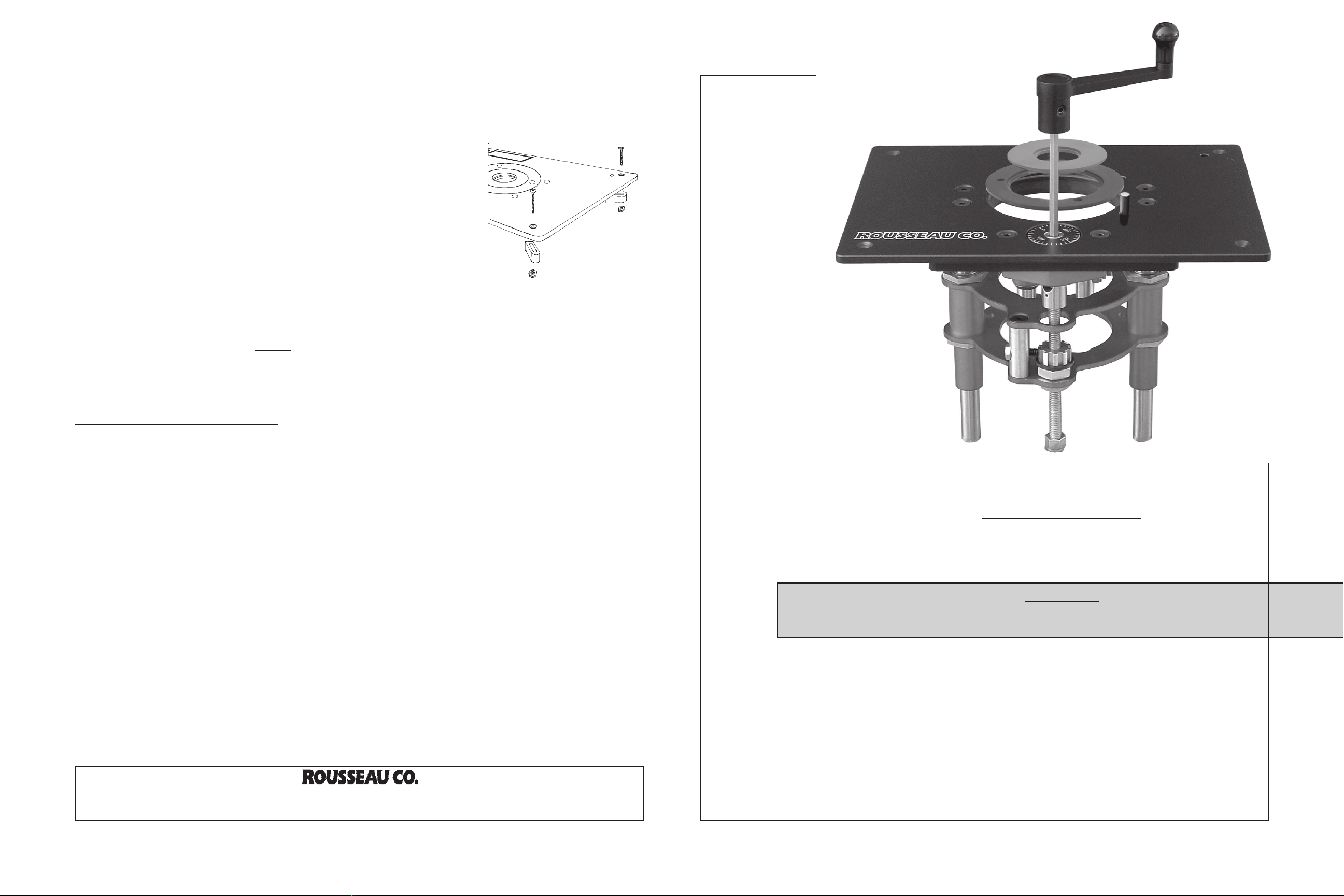

You have purchased a ROUSSEAU CO. 3000 SERIES ROUTER LIFT LS. This product is designed to allow quick

and easy bit height adjustment from the top of your table by fast and accurate raising and lowering of the router.

WARRANTY

This product has a lifetime warranty to the original purchaser that applies to defects in materials and workmanship

only. We will repair or replace the product or part(s) at our discretion. This warranty does not apply to product

failure or defects due to direct or indirect misuse, abuse, negligence, accidents, alterations, repairs or lack of

maintenance. The item must be shipped prepaid to our Clarkston, WA location. If items must be returned for

warranty service, call to receive a Return Goods Authorization (RGA) number and further instruction.

SAFETY GUIDELINES

THIS SECTION CONTAINS IMPORTANT SAFETY INFORMATION CONCERNING A HAZARD THAT MAY

CAUSE SERIOUS INJURY OR DEATH, and/or damage to stand or equipment if used improperly. Please read the

following instructions very carefully.

Always follow the safety recommendations and guidelines provided by the manufacturer of your

tools and supplies. When in doubt refer to your owner’s manual.

Always wear eye protection. Failure to do so may cause severe injury and/or loss of sight.

Always keep fingers clear of cutter. Failure to do so could result in serious injury or loss of fingers.

Never wear loose clothing while operating equipment. It may become entangled in router bit caus-

ing severe injury or death.

Always use guards and hold downs to protect you and your workpiece. Operation without guards

could result in loss of fingers, severe injury or death.

Carefully check router bits before each use. Do not use if damage or defect is suspected.

Unplug any tool or machine when changing bits or making mechanical adjustments.

OPERATION GUIDELINES

THIS SECTION CONTAINS IMPORTANT OPERATIONAL INFORMATION CONCERNING HAZARDS THAT

MAY CAUSE SERIOUS DAMAGE TO PRODUCTS OR TOOLS IF USED IMPROPERLY. Please read the

following instructions very carefully.

Never use a power drill to raise and lower the lift carriage. The amount of friction and heat will

cause premature wear of the threads

Never force the bit or overload the router.

Be sure at least ¾ of the shank on the bit is inserted securely in the router collet.

Never bottom the bit in the collet. Allow 1/8” clearance at bottom of bit.

Make sure router fence is locked into position before use.

Always rout in two or more passes when removing large amounts of material.

Reduce RPM speed for large diameter bits.

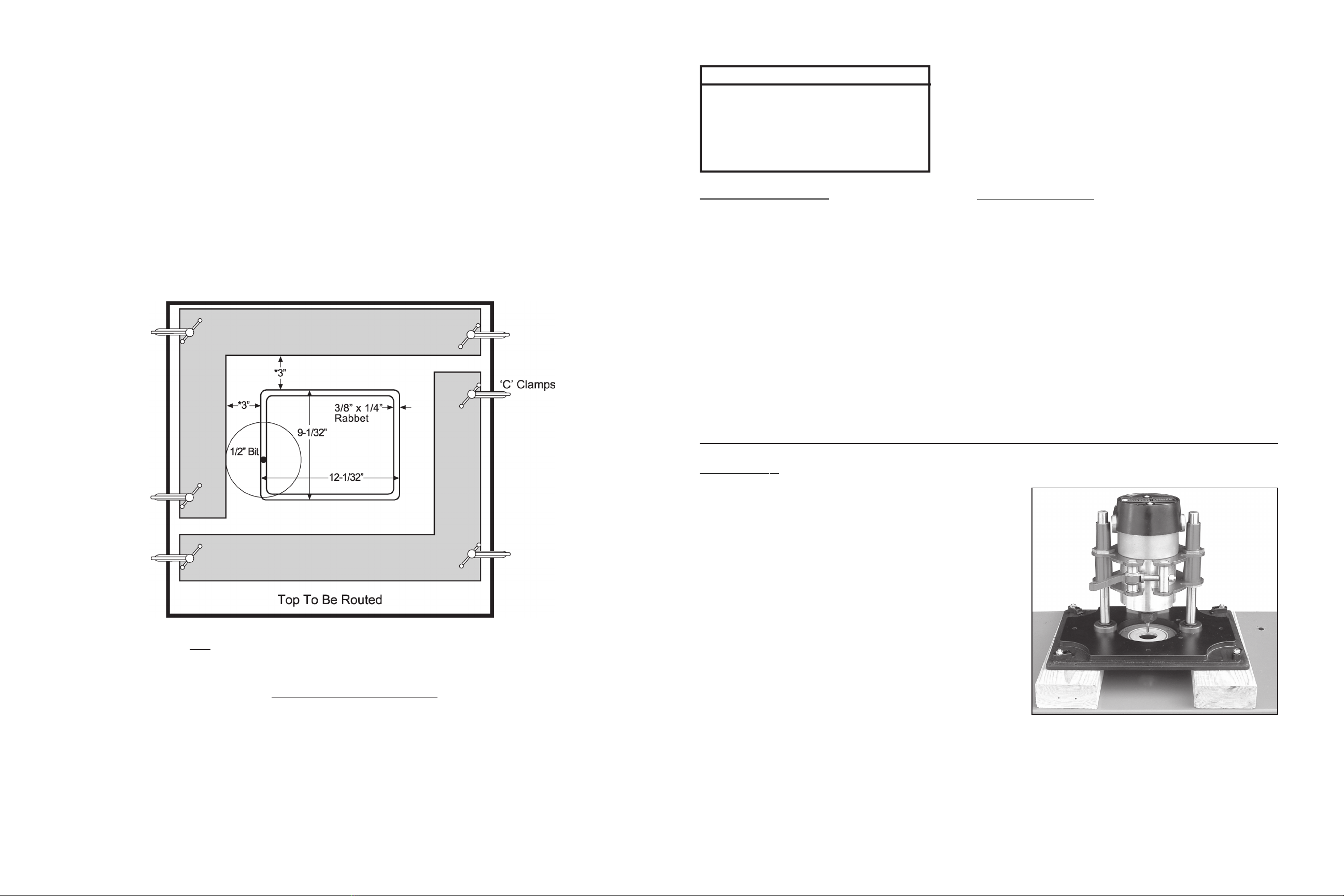

After routing the baseplate hole into your table by following the Baseplate

Installation Instructions or using the 3509-T Installation Template, proceed

through the following steps to install the leveling system.

1. Mark the location for the six brass inserts. There will be one located in

each corner and one on each long side. Fig. A

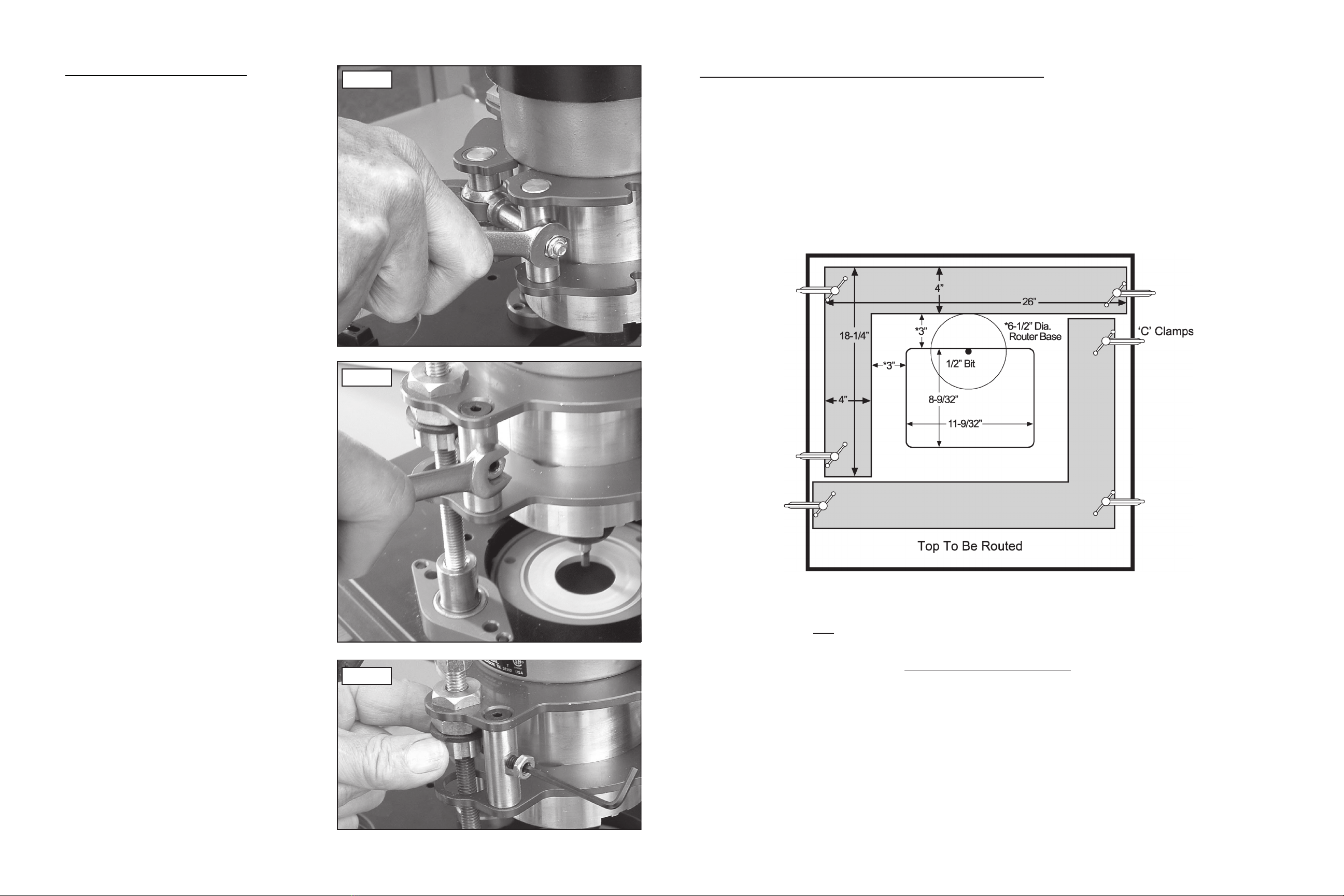

2. Clamp a block of wood below the location of each hole to eliminate tear-

out. Drill each hole using a 7/32” drill bit. Take care to assure that the

holes are perpendicular to the tabletop. Fig. B

3. Press one insert into each hole from the top of the table until flush with the

surface. This can be done by threading the insert onto the end of a 10-24

screw (the corner snugger mounting screws will work) and driving it gently

with a hammer. Fig. C

4. Thread one nylon leveling screw into each insert from the bottom side of

table.

5. Place baseplate into the table and adjust each leveling screw to desired

height. Fig. D

NOTE: THE weight of the router should create sufficient resistance to

hold leveling screws in place. However, more resistance can be achieved

by distorting the leveling screw threads slightly using pliers. Fig. E

INSTALLATION OF BASEPLATE LEVELING SYSTEM

Fig. E

Fig. D

Fig. C

Fig. B

Drill 6-7/32 Holes

Centered In Routed Surface

Fig. A

Drill Into

Wood Block

To Prevent

Tear-Out

Drive Insert

Lightly With

10-24 Metal

Screw &

Hammer

Routed & Drilled

Table Top

Base Plate

Leveling

Screw

Table Top

Plier Jaws

Leveling Screw

Distort Thread with Plier to Tighten