1

1. WARNING

This instruction manual is an integral part of the

machine and must be kept for any further

consultation.

Never try to use this machine for applications which

are not described in the instructions or for the unit’s

intended purpose.

This machine should be used only for the purpose for

which it was designed. Any other use is inappropriate

and dangerous. The manufacturer will not be held

responsible for any damage caused by improper use.

Before installing and operating on the machine read

the operation manual.

Unplug the machine from outlet when not in use,

before putting on or taking off parts, and before

cleaning. Do not power unit through a power board or

extension cord.

Be sure to unplug the machine if not using the

machine for a long time.

If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or licensed

electrician persons to avoid a hazard.

Do not use the machine in a dusty environment or in

an explosive atmosphere (inflammable gases and

vapors from organic solvents).

Repairs, when necessary, must be performed by an

authorised service agent.

The machine is suitable for indoor use only.

Basic safety rules:

a. Do not touch the machine when hands or feet are

wet.

b. Do not allow the machine to be used by children or

untrained persons.

c. Do not pull on the electrical cord when unplugging

the machine.

2.

INSTALLATION

2.1 Transportation

Please keep the unit upright during transportation.

Any excessive tip or lean may cause damage to the

unit internally.

If the machine is not upright during transportation,

you must leave the unit without powering on to sit for

24 hours before turning the unit on.

2.2 Storage

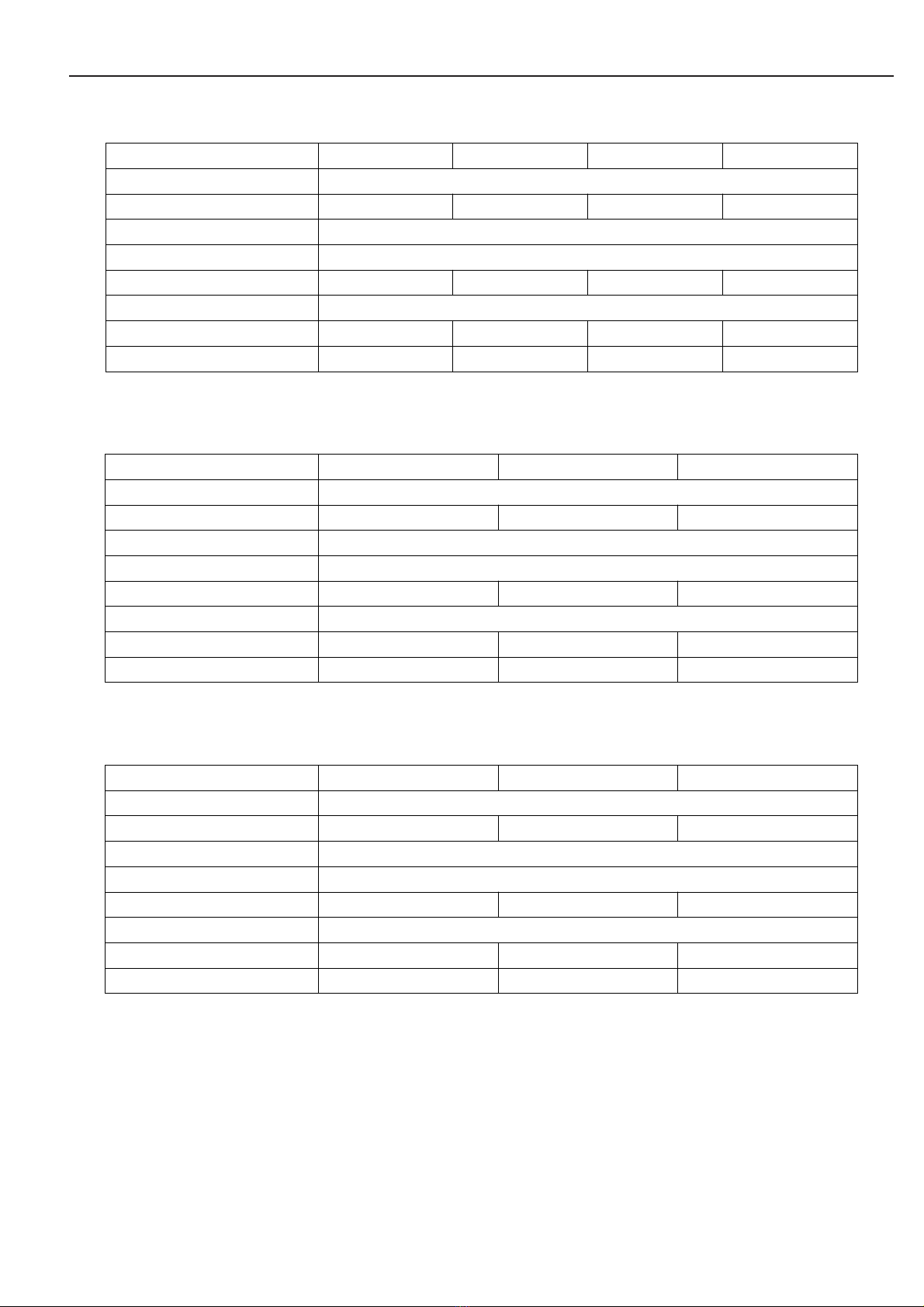

The unit must not be double stacked. (Fig.1)

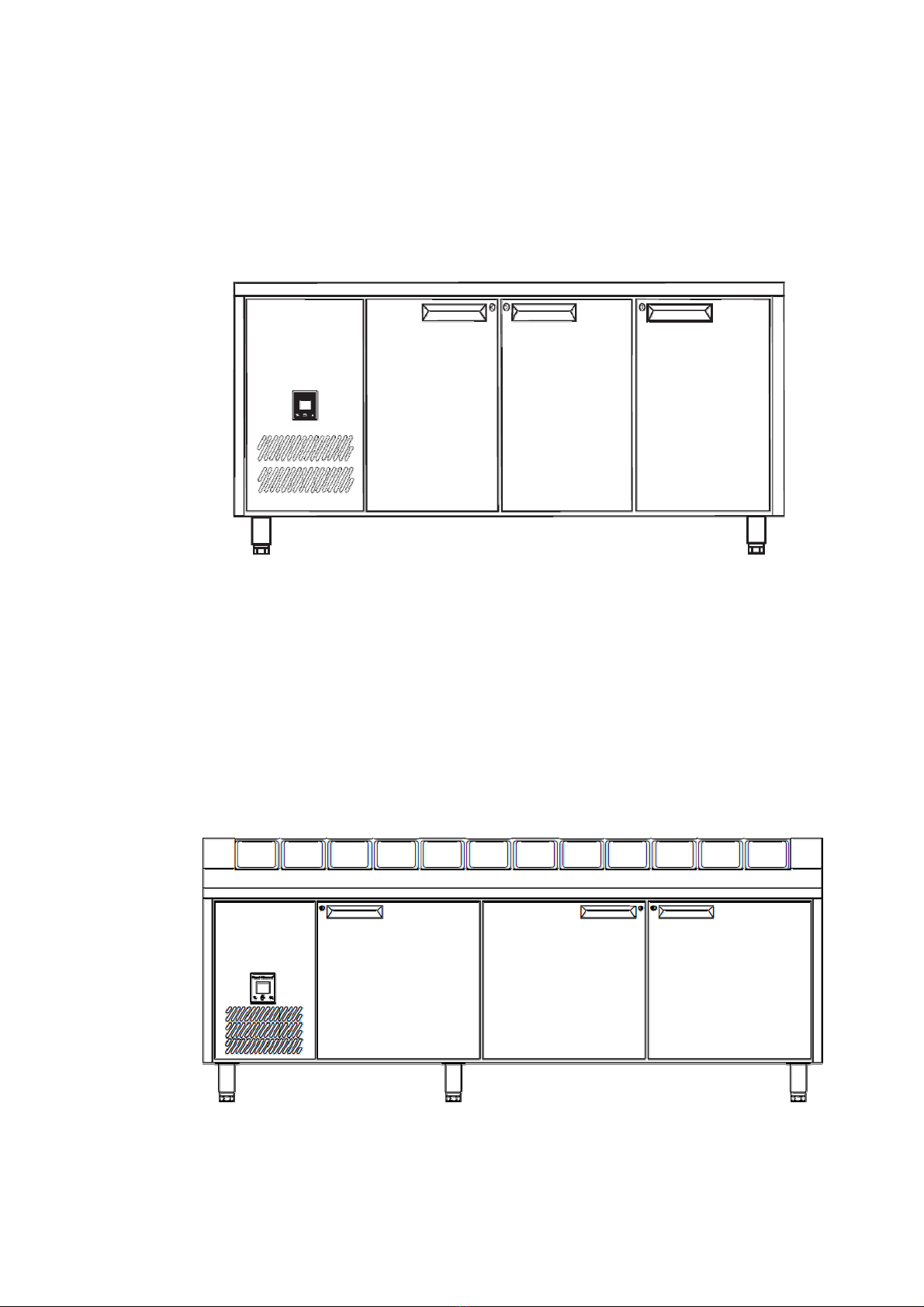

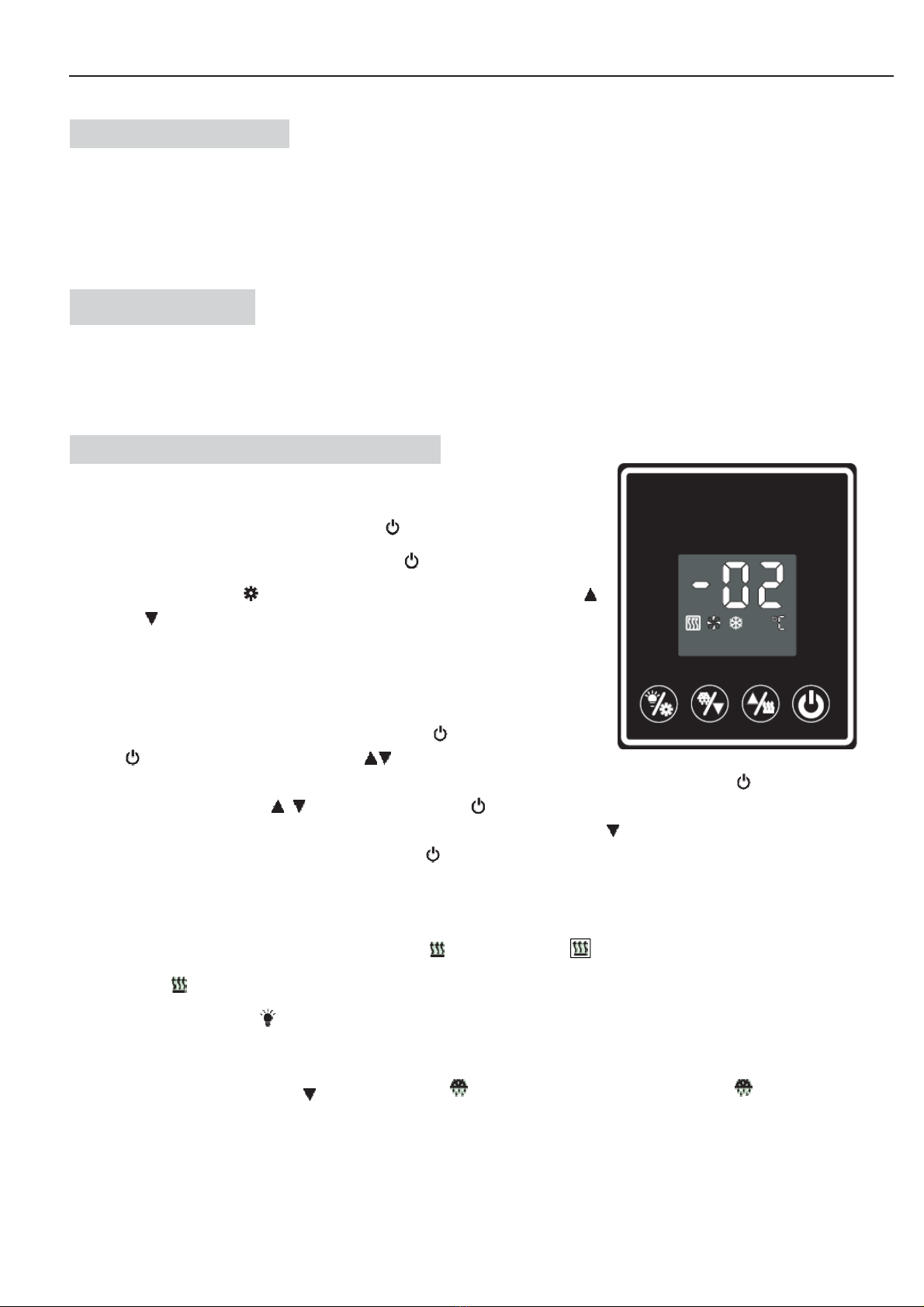

Fig.1

2.3 Unpacking

Please remove all packaging materials including the

protective film on the stainless steel.

.

2.4 Refrigerator Installation

Do not install the machine in the area where it can be

damaged by water.

This unit is intended for indoor use only.

Place machine on a flat and sturdy surface.

For good ventilation, keep a distance of 100mm

between unit and wall or other objects. Increase the

distance if the objects are a near a heating source.

When the display is in place, press the brake on the

wheels to keep it level and secure.