Johnson Controls YORK YCAL0043E Series Owner's manual

Other Johnson Controls Chiller manuals

Johnson Controls

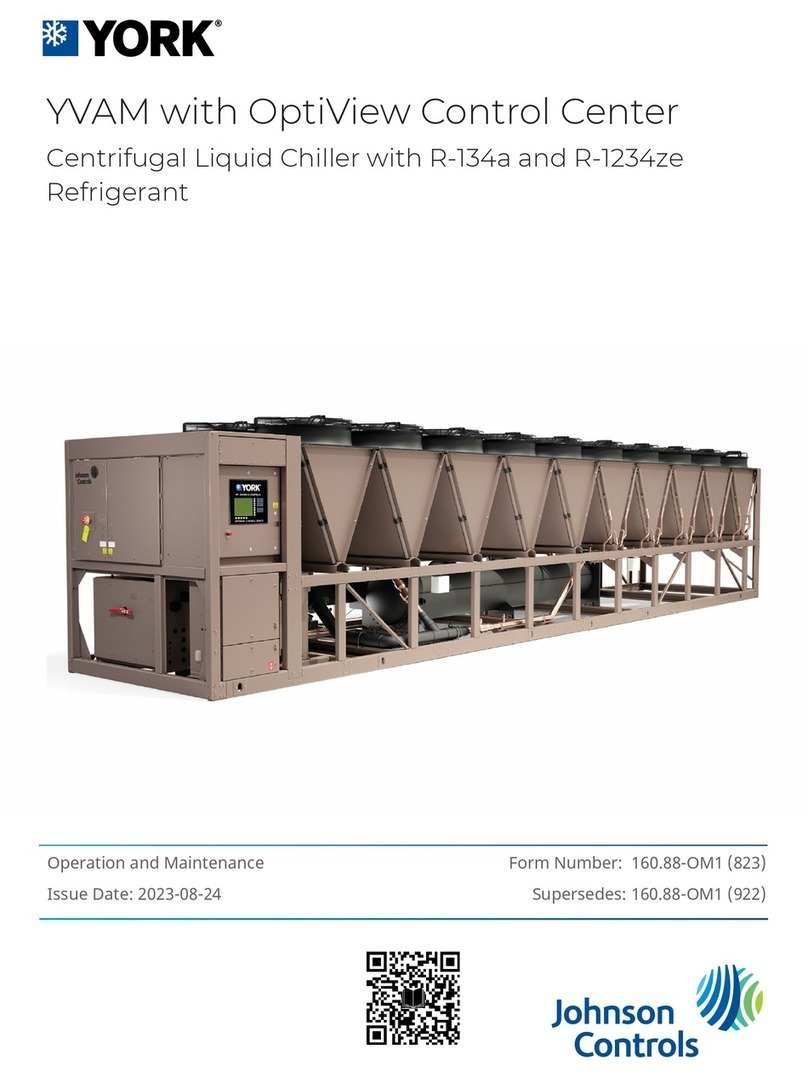

Johnson Controls YORK YVAM User manual

Johnson Controls

Johnson Controls York YCAL0041-0071 User manual

Johnson Controls

Johnson Controls SABROE ChillPAC User manual

Johnson Controls

Johnson Controls York YCRL0064 Owner's manual

Johnson Controls

Johnson Controls Frick PowerPac Owner's manual

Johnson Controls

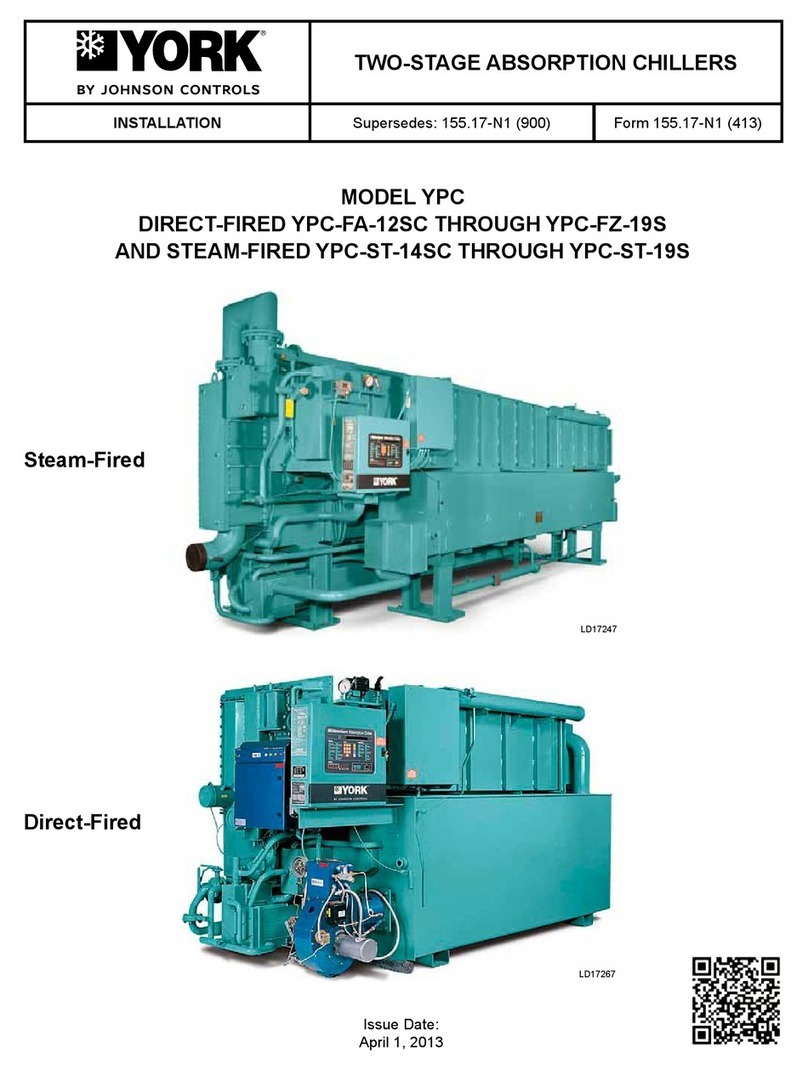

Johnson Controls YORK YPC Series User manual

Johnson Controls

Johnson Controls York YKEP Series User manual

Johnson Controls

Johnson Controls York YCAL0012-0032 User manual

Johnson Controls

Johnson Controls YORK OM Titan User manual

Johnson Controls

Johnson Controls York YCRL0200HE Owner's manual

Johnson Controls

Johnson Controls York YCSE 040 User manual

Johnson Controls

Johnson Controls SABROE ChillPAC User manual

Johnson Controls

Johnson Controls YORK YK Series User manual

Johnson Controls

Johnson Controls York YHAU-C Installation and operating instructions

Johnson Controls

Johnson Controls YORK YAES-SA User manual

Johnson Controls

Johnson Controls SABROE ComPAC User manual

Johnson Controls

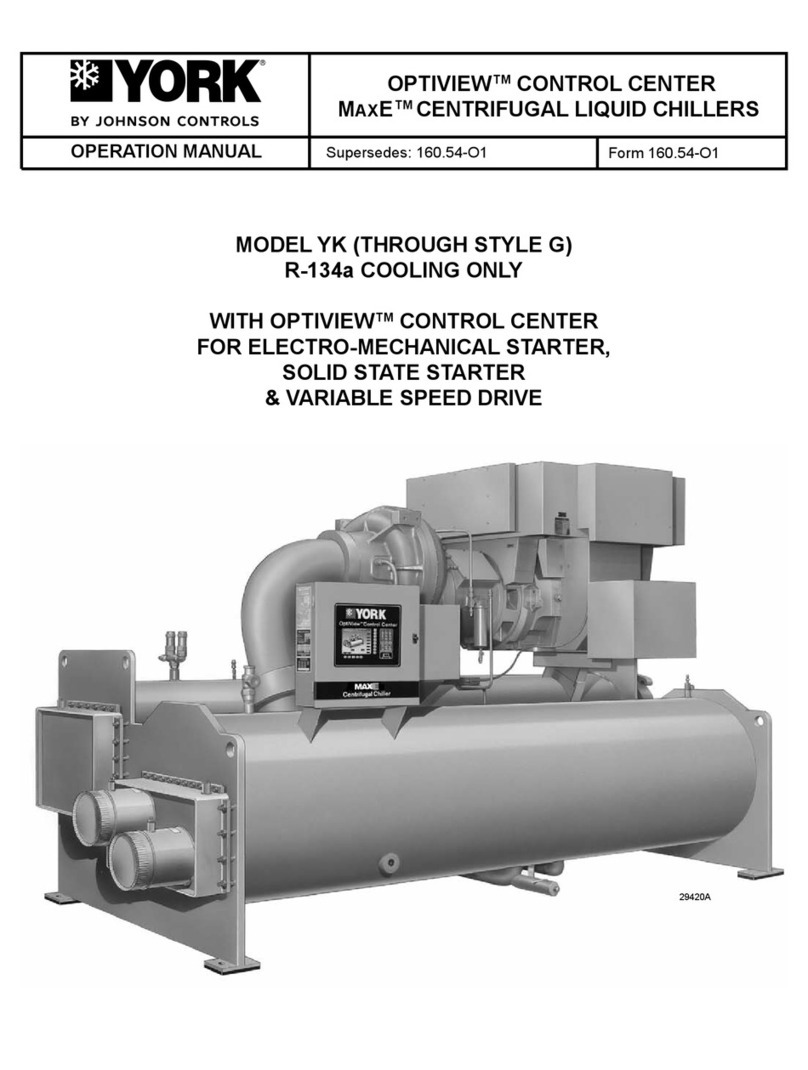

Johnson Controls York MaxE YK Series User manual

Johnson Controls

Johnson Controls RW Series Owner's manual

Johnson Controls

Johnson Controls YORK YMC2 User manual

Johnson Controls

Johnson Controls York YCAL0014E Series Guide

Popular Chiller manuals by other brands

Telemark

Telemark TVP-2000 Operation, installation and service manual

TICA

TICA MINI VRF CHR Series Installation & operation manual

Penguin

Penguin COLD THERAPY CHILLER owner's manual

MAXA

MAXA A68 Installation and operation manual

SABROE

SABROE ChillPAC operating manual

Daikin

Daikin EWWQ-AJYNN Service manual