●All Multi-mode Fiber Optic cable should be terminated (Type ST Connectors)and tested by

a qualified fiber optic technician.

Electrical Terminations

1. If BBU is provided by RSSI, local commercial power (Typically 120/240 V) 1P 3 wire 30A is

wired to Battery Backup Panel (BBP) at MAIN CB-1 (L1 –L2, - Ground). If no BBU commercial

power will connect to Top of Main Disconnect Switch in Barrier Control Panel.

2. BBP transfers power to Barrier Control Panel (BCP) MAIN Disconnect Switch.

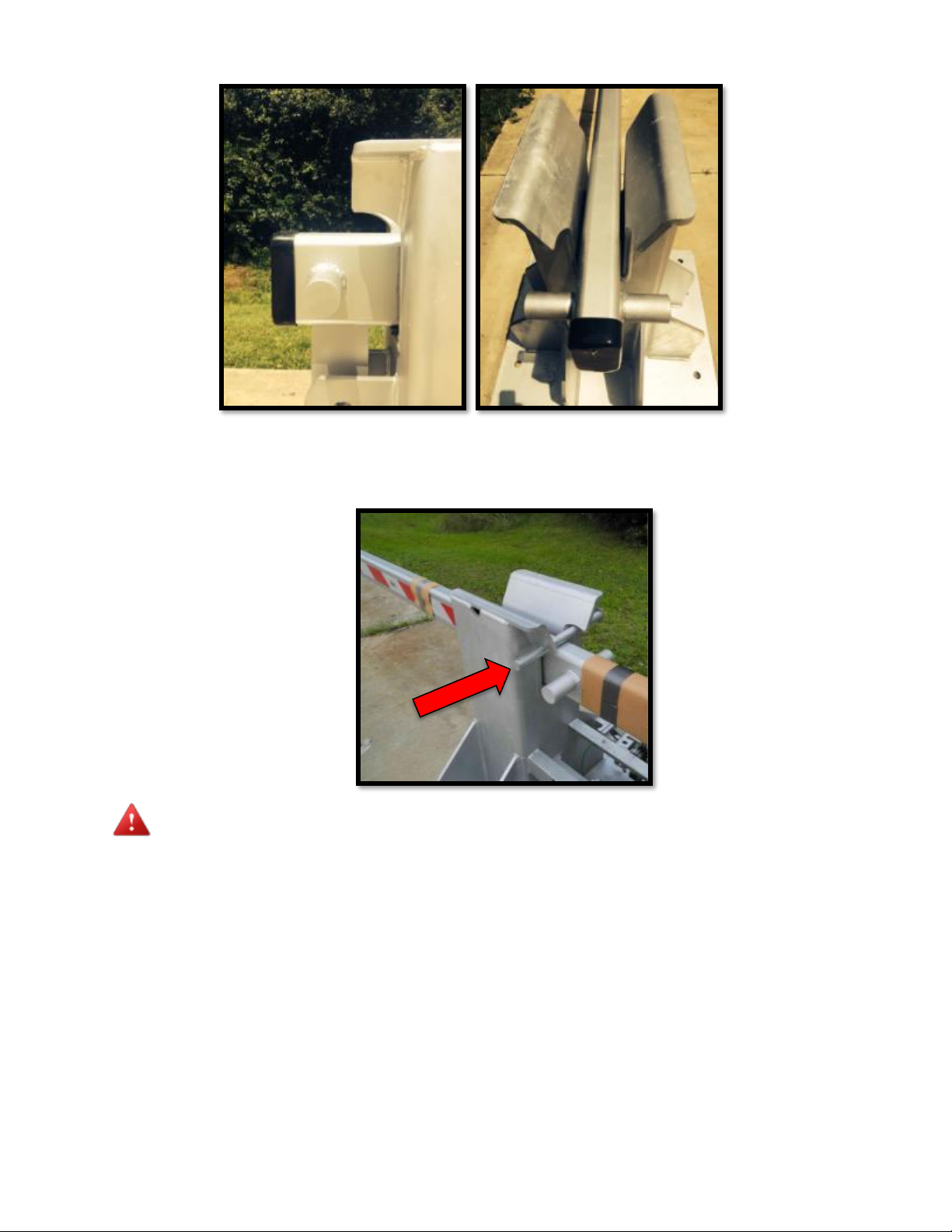

3. Servo Drive is located in BCP. The Motor and Encoder cables will be pulled from barrier

throughappropriateJ-Box(Orange=Power/Green=Control)thenintoBCP. Note:Ifdistanceisover

90 feet from BCP to Actuator contact RSSI for assistance.

4. If Actuator Heat Pad is supplied, the Heat Pad is powered through the BCP terminals 1H1 and

1H2 and wired to the Barrier Power J-box (splices). Ground wire will need to be pulled to J-Box as

well (check conduit legend for wire gauge needed). 3 Wires need.

5. The 24Vdc Traffic Lights are powered through the BCP PLC outputs and terminal blocks.

6. The 24Vdc Barrier Warning LED Lights are powered through the BCP PLC and wired through

the Control J-Box then terminated in J-Box. 2 wires needed

7. The IR Beams (if applicable) are powered through the BCP +24Vdc (Red wire)/-24Vdc (Black

wire) power terminal blocks to each IR Beam (splices in stands) Connect the Red wire to Brown

and Gray wires of IR pigtail and Black wire to Bluewire of IR pigtail.

8. The Barrier Heat Thermostat (mounted outside Panel) is connected at BCP terminals +24Vdc

and PLC input (splices at thermostat); if applicable.

Control Terminations

1. Servo DriveinBCP,anin-linebreakout board willneedtobeterminatedandpluggedintoServo

Drive in Panel.

2. BCP receives vehicle presence indications from the LOOPS in the roadway to the front of the

LOOP DETECTORS in the BCP. (Bottom DIP switch must be set to right position at this point).

3. BCP receives INPUTS from IR Sensor (if applicable) (black wire on sensor pigtails) the black

wire is connected to blue wire connected on PLC.

4. BCP controllerreceivesacontactclosurefromthethermostat(mountedoutside)totheBCP PLC

inputs. This activates the barrier heat grid system.

5. If BBU is provided, BCP receives INPUT from Battery Backup Panel (BBP) when commercial

power is lost and/or when a Low Voltage condition is present. BBP terminations are marked

(+24VDC) 13 and 14. The BCP terminations are mark (+24VDC), (I:1/0) for Loss of Power and

(I:1/1) for Low Voltage condition.