Page 4 of 28 Sym B .

Dwg. 56201-2 .

TABLE OF CONTENTS

Para. Description Page

None Title Page......................................................................................................................1

None Revision Notice.............................................................................................................2

None Proprietary Notice .........................................................................................................3

None Table of Contents..........................................................................................................4

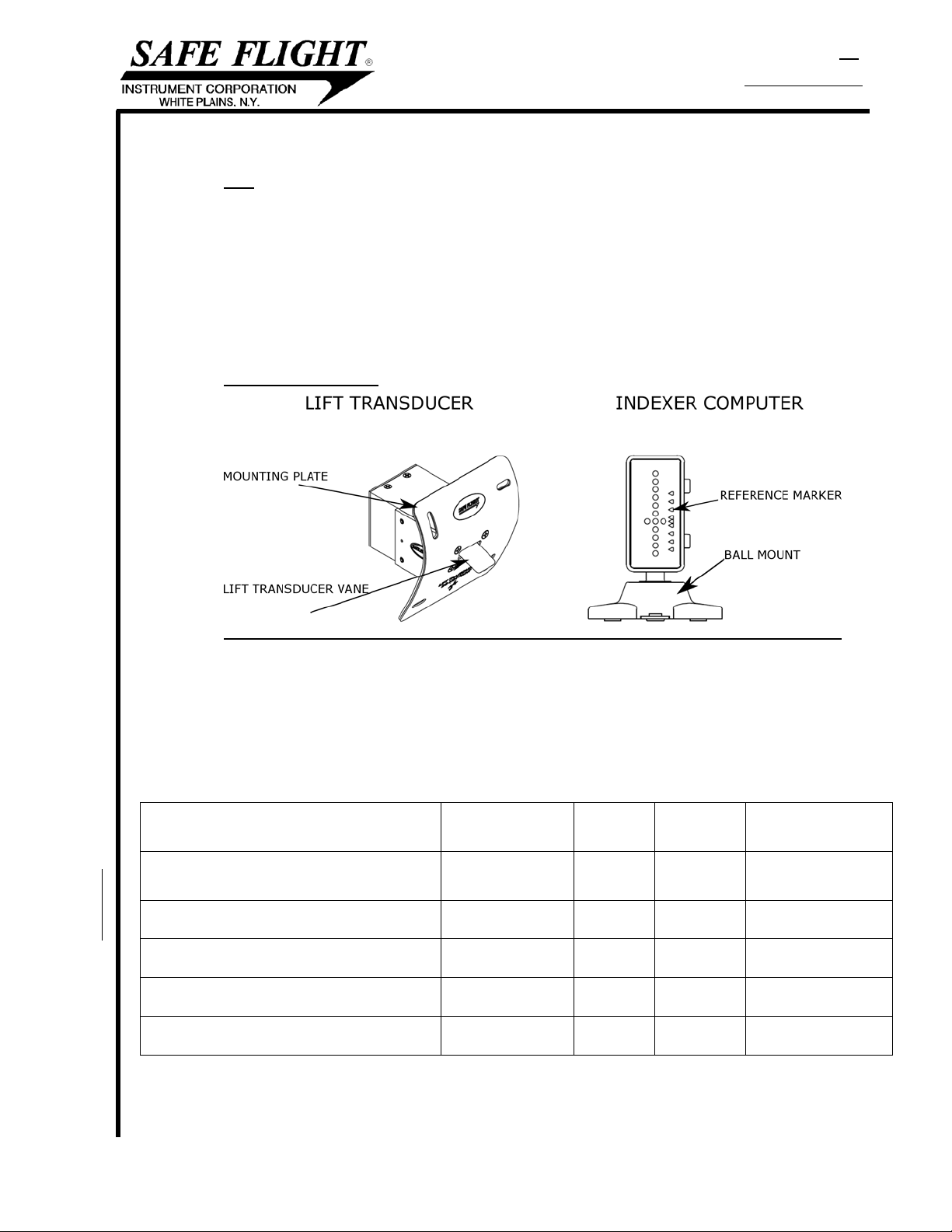

System Description.......................................................................................................51.01.1 SCc................................................................................................................................5

1.2 System Components.....................................................................................................5

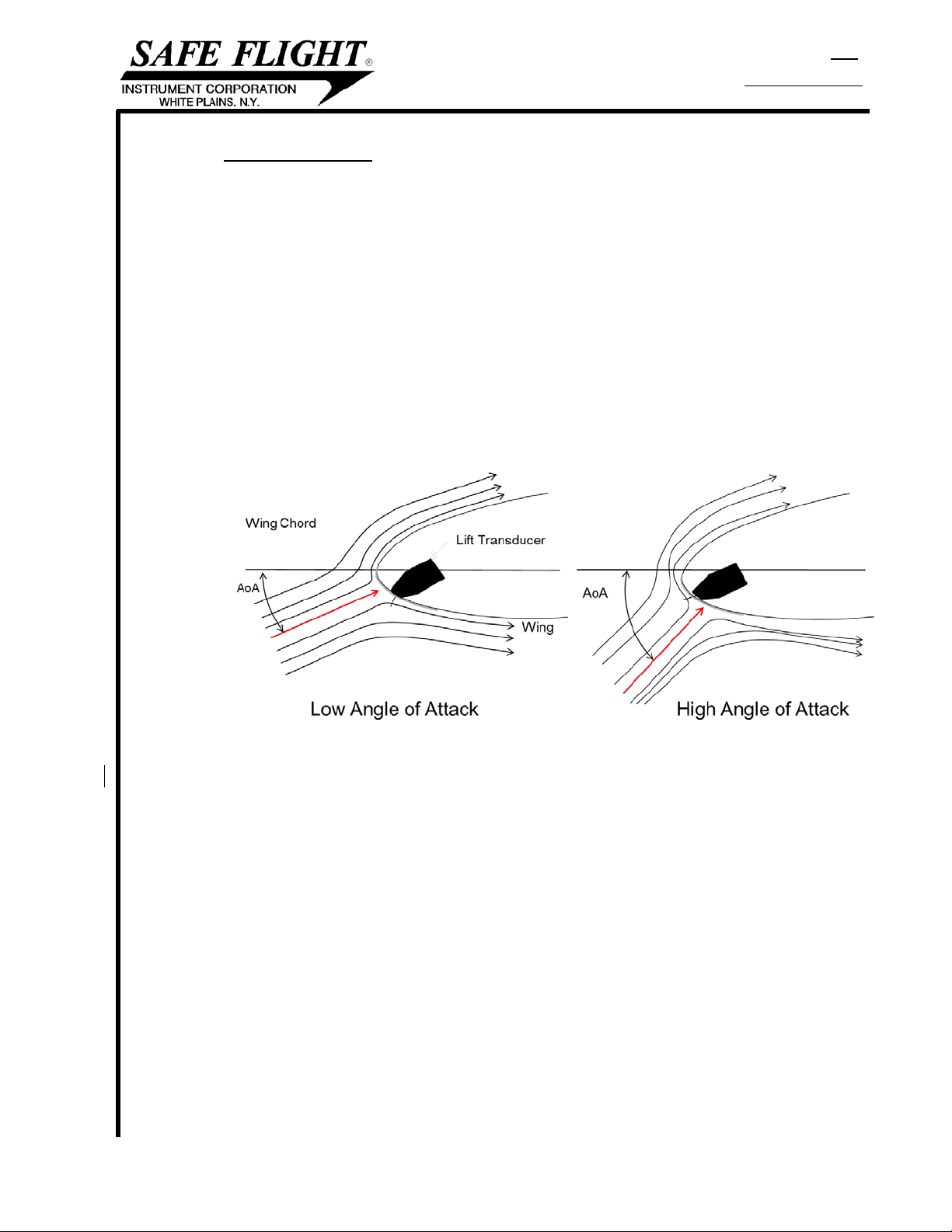

1.3 Theory of Operation......................................................................................................7

1.4 Scope............................................................................................................................8

1.5 Limitations.....................................................................................................................8

1.6 Specifications................................................................................................................8

Installation, Adjustment and Functional Check.............................................................92.02.1 Installation Procedure ...................................................................................................9

2.2Lift Transducer Wing Position.......................................................................................9

2.3 Doubler Installation .......................................................................................................9

2.4 Indexer Computer .......................................................................................................10

2.5 System Wiring.............................................................................................................13

2.6 Lift Transducer Installation..........................................................................................13

2.7 Ground Functional Test ..............................................................................................13

Flight Check and Adjustment......................................................................................143.03.1 Background.................................................................................................................14

3.2 Transducer Location Verification Flight.......................................................................14

3.3 In-Flight Final Calibration Adjustment.........................................................................15

3.4 Final Lift Transducer Installation.................................................................................16

3.5 Precautions .................................................................................................................16

3.6 Weight and Balance....................................................................................................16

Troubleshooting ..........................................................................................................164.04.1 System Removal.........................................................................................................16

4.2 Failure Modes .............................................................................................................17

4.3 Instructions for Continued Airworthiness ....................................................................17

User Manual................................................................................................................185.05.1 General .......................................................................................................................18

5.2 System Display ...........................................................................................................18

5.3 Pre-Flight Ground Check Procedure...........................................................................18

5.4 Additional Button Press Functions..............................................................................19

5.5 Takeoff and Climb.......................................................................................................20

5.6 Cruise..........................................................................................................................20

5.7 Landing Approach.......................................................................................................22

5.8 Low Airspeed Awareness (LAA) .................................................................................23