LN1000 IS Annunciator

3

TABLE OF CONTENTS

TABLE OF CONTENTS..............................................................................................3

SECTION 1 INTRODUCTION.....................................................................................6

SECTION 2 SYSTEM DESCRIPTION & FEATURES ................................................7

GENERAL .............................................................................................................................. 7

CERTIFICATION...................................................................................................................... 7

SYSTEM SIZES....................................................................................................................... 7

COMPLETE SYSTEM............................................................................................................... 7

PROGRAMMABILITY................................................................................................................ 7

MOUNTING ............................................................................................................................ 7

SERVICING ............................................................................................................................ 8

LIGHTWEIGHT........................................................................................................................ 8

GROUP OUTPUTS.................................................................................................................. 8

INPUTS.................................................................................................................................. 8

SECTION 3 INPUTS & OUTPUTS............................................................................10

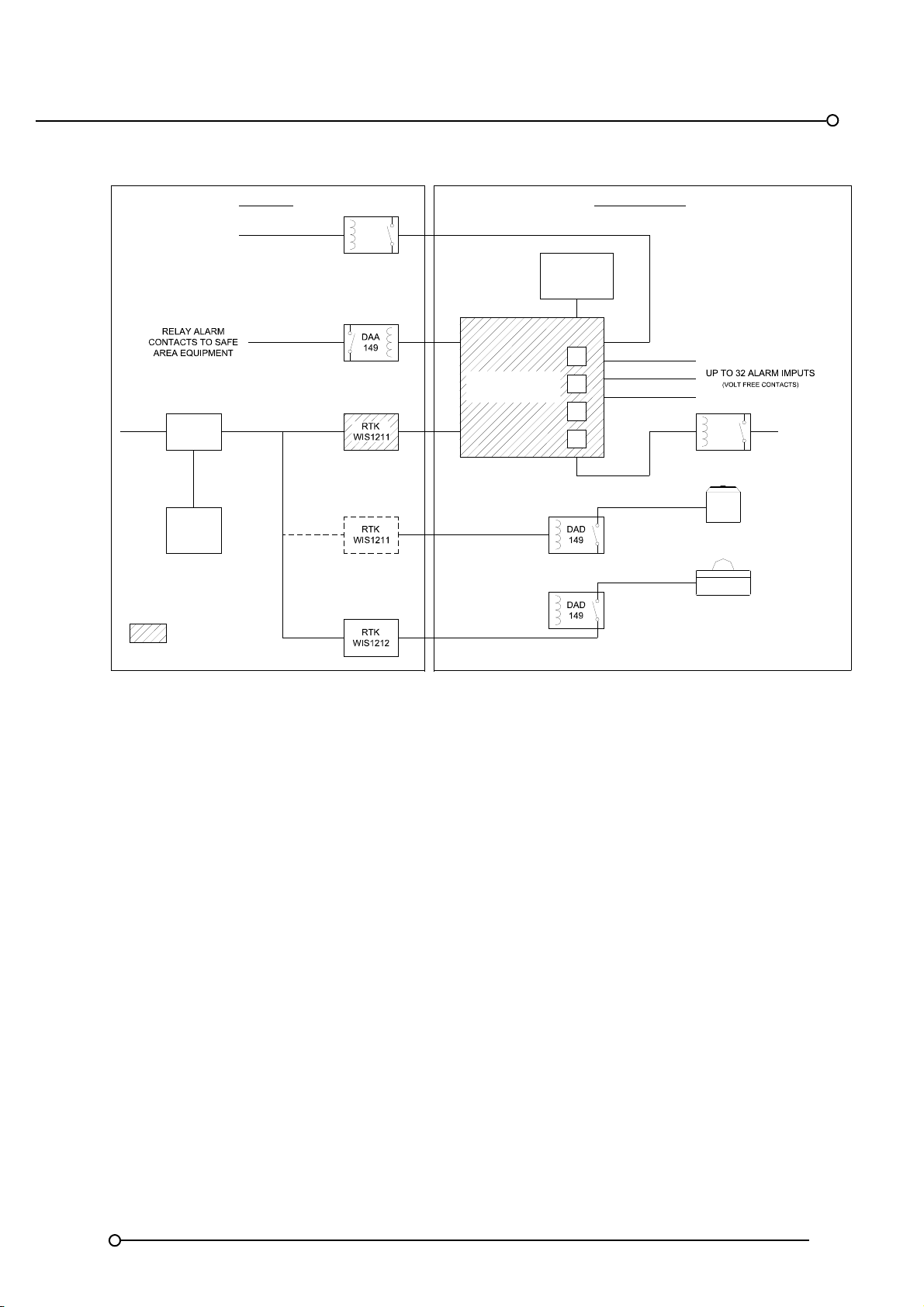

TERMINATIONS AND INTERCONNECTIONS.............................................................................. 10

LN1000-AC ALARM CARD................................................................................................... 10

LN1000-SC SEQUENCE CARD............................................................................................. 10

SECTION 4 TECHNICAL SPECIFICATION.............................................................11

LOCATION ........................................................................................................................... 11

POWER REQUIREMENTS ...................................................................................................... 11

TERMINALS.......................................................................................................................... 11

EMC COMPLIANCE............................................................................................................... 11

ENVIRONMENT..................................................................................................................... 11

ENVIRONMENTAL PROTECTION ............................................................................................ 11

CONSTRUCTION................................................................................................................... 11

PANEL CUT OUT.................................................................................................................. 11

WEIGHT .............................................................................................................................. 11

ALARM INPUTS .................................................................................................................... 12

INHIBIT INPUTS .................................................................................................................... 12

ALARM OUTPUTS................................................................................................................. 12

PROGRAMMABLE FEATURES ................................................................................................ 13

LN1000-SC SEQUENCE CARD............................................................................................. 13

INPUT.................................................................................................................................. 13

OUTPUTS ............................................................................................................................ 13

PUSH BUTTONS................................................................................................................... 14

OTHER FEATURES............................................................................................................... 14

SECTION 5 MECHANICAL DETAILS......................................................................15

ALARM CHASSIS.................................................................................................................. 15

FASCIA PANEL..................................................................................................................... 15

ALARM CARDS..................................................................................................................... 15

SEQUENCE CARD ................................................................................................................ 15

PANEL MOUNTING ............................................................................................................... 15

WALL MOUNTING................................................................................................................. 16