1. SAFETY INSTRUCTIONS

This machine is designed for safe use. This can only be achieved if you completely follow the safety

instructions described in this manual.

Read and understand the manual before you start using this machine.

If the machine is not used as described in this manual, this can result in injuries and/or damage to the

machine.

This user manual lists instructions that are numbered in sequence. You should follow this sequence.

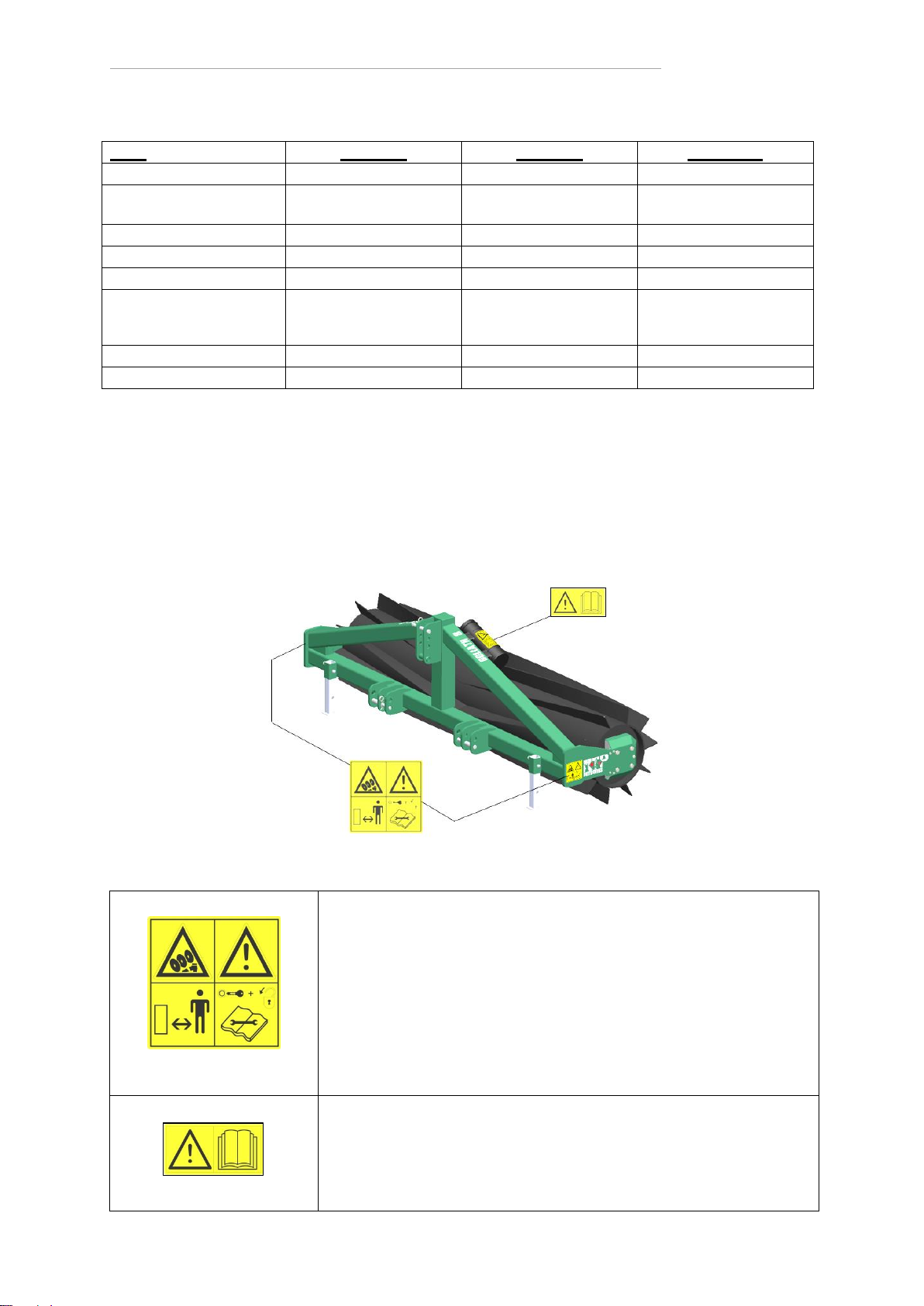

A is an indication of a safety instruction. A means a tip and/or note.

1.1. Obligations of the user

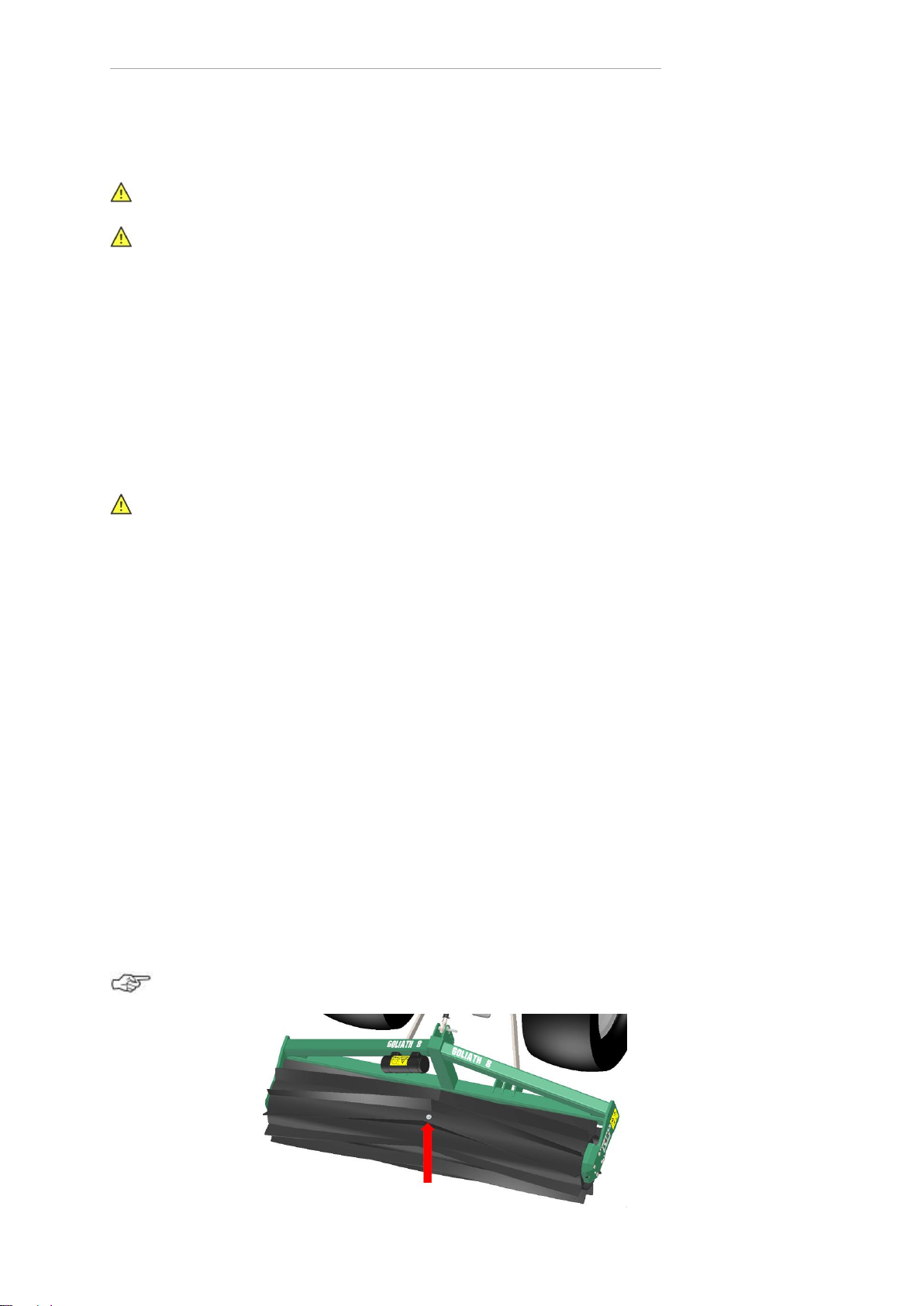

The machine is solely intended for crop flattening tillage on natural areas. Any other use is improper.

The manufacturer will not accept any liability for damage resulting from improper use. All risks

occurring with this are entirely at the expense of the user.

All persons assigned to operate, maintain and repair the machine by the owner must completely read

and understand the operation manual and in particular the chapter of Safety Instructions.

Modifications to the machine that have a negative impact on the safety must be rectified immediately.

The user is obliged to check the machine for visible damage and defects before using the machine.

For safety reasons it is not permitted to make changes or adjustments to the machine (except those

approved by the manufacturer). If modifications to the machine have been made, then the current CE

marking is cancelled. The person that has made these modifications has to apply for a new CE

marking himself.

Following the use, maintenance and repair instructions prescribed by the manufacturer is also

considered proper use of this machine.

The user is responsible for the safe combination of the machine and the towing vehicle, which comply

with the requirements as described in the Technical Data (see Chapter 2). This entire combination

should be tested for noise, safety, risk and user friendliness. User instructions should also be drafted.

Dress appropriately during work activities with the machine. Wear sturdy shoes with protective

toecaps, long trousers and tie up long hair. Do not wear loose clothing.

The general applicable health & safety regulations must also be followed in addition to the instructions

in this user manual.

Relevant traffic regulations also apply in case of using public roads.