6| MPC...D.F4 T

EN

Installation, operating and maintenance instructions

5. PRODUCT INFORMATION

4. ADHERE TO THE FOLLOWING INSTRUCTIONS

4.1. General instructions

■Persons who assemble, operate, disassemble or maintain our devices must not be under the influence of alcohol,

drugs or pharmaceuticals that may affect perception and responsiveness.

■Responsibilities for the operation, maintenance and regulation of the product should be clearly determined and

observed so that there can be no unclear areas of responsibility with regard to safety.

4.2. Indications assembly

■Disconnect all of the product‘s poles from the mains before installing the product or connecting or removing plugs.

Make sure that the product cannot be switched back on again.

■Lay cables and lines so that they cannot be damaged and no one can trip over them.

■Information signs must not be changed or removed.

4.3. Indications Commissioning

■Make sure that all electrical connections are either used or covered. Commission the product only if it is installed

completely.

■e power switch must always be fully functional and easy accessible!

■Only authorized personnel is allowed to operate the setting mechanisms of the components or parts, under the

provision that the system is used as intended.

■In an emergency, or if there is a fault, or other irregularities, switch the equipment off and make sure it cannot be

switched back on again.

■e technical data given on the rating plate must not be exceeded.

4.4. Indications during operation

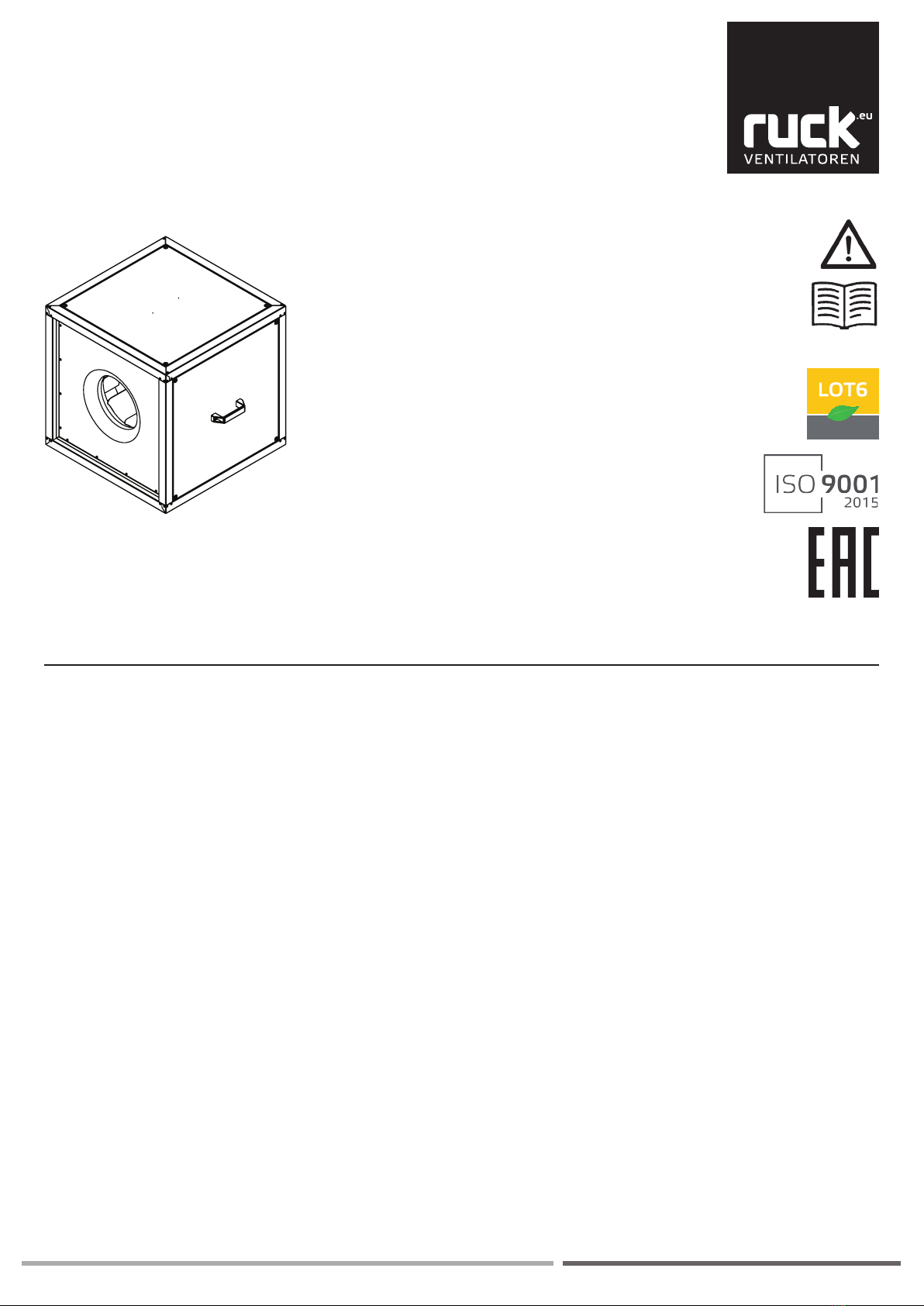

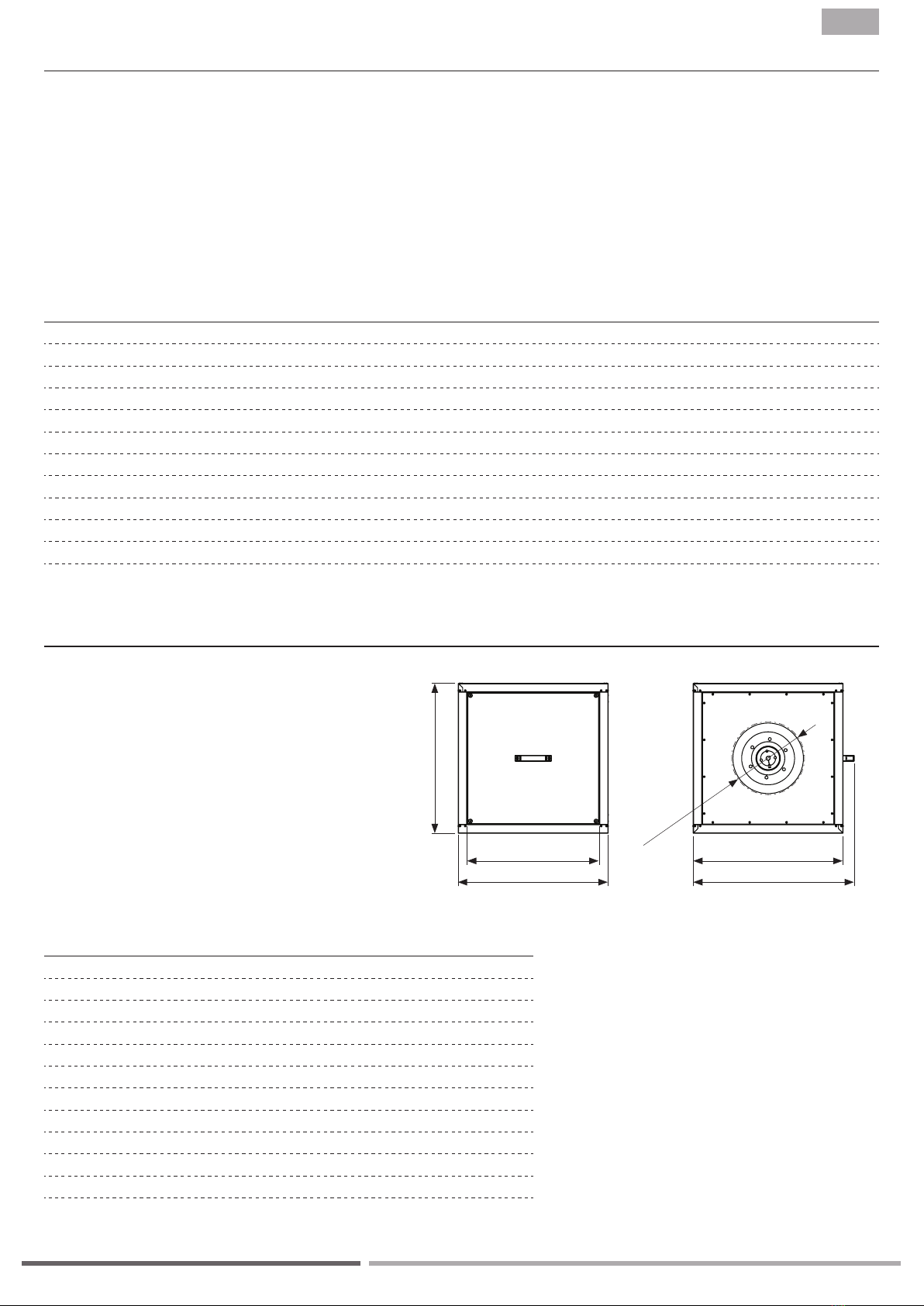

Description:

■Smoke extract fan for exhaust air applications

■is exhaust box with smoke extraction function can reliably deliver up to 400°C hot combustion gases in case

of fire for 2 hours. e exhaust air box must be replaced after a fire incident. Recurring operation at 400 °C is not

allowed.

■Conveyed exthaust up to 200 °C

■Radial impeller

■With condensate drain

■Motor outside the air stream (VDI 2052))

■Motor protection on site

■Tested according to EN 12101-3

■e back curved high-performance impeller consists of powder-coated sheet steel and is mounted on the shaft of

a standard three-phase motor. Impeller dynamically balanced in 2 planes according to quality standard G 6.3, DIN

ISO 1940. e ball-bearings are maintenance-free and lifetime lubricated. e motor is located outside the airflow.

■e built-in 3-phase motor with IE-3 classification can only be controlled by means of a frequency converter!

■Double wall cubic housing made of galvanized sheet steel with 30 mm thick mineral wool insulation, non-flammab-

le according to DIN EN 13501-1, class A1. Device bottom with integrated base pan and condensate drain.

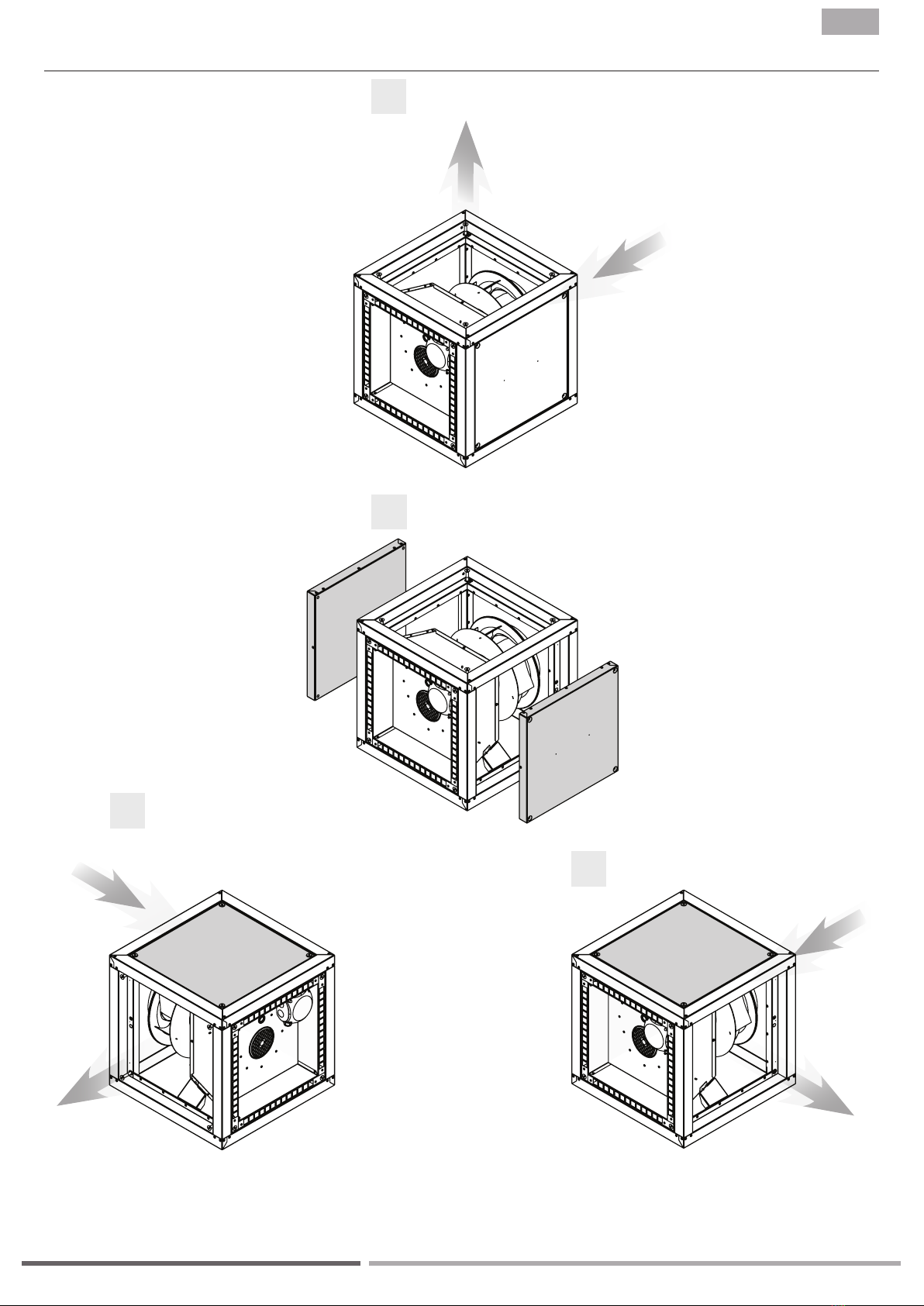

For cleaning and maintenance work, the full-surface inspection door can be removed using the door handle. e door

handle is included loose and can be mounted on the desired side. e side walls as well as the cover can be easily remo-