D.2 Electrical

WARNING

Disconnect heater from power supply at integral disconnect or

fuse box before opening enclosures or servicing heater.

IF INTEGRAL DISCONNECT IS BEING SERVICED, verify that

power has been disconnected at fuse box or main panel. Lock

the switch in the "OFF" (open) position and/or tag the switch to

prevent unexpected power application. Installation and wiring of

the heater must adhere to all application codes.

1. General

1.1 Use only copper conductors and approved

explosion-proof wiring methods during installation.

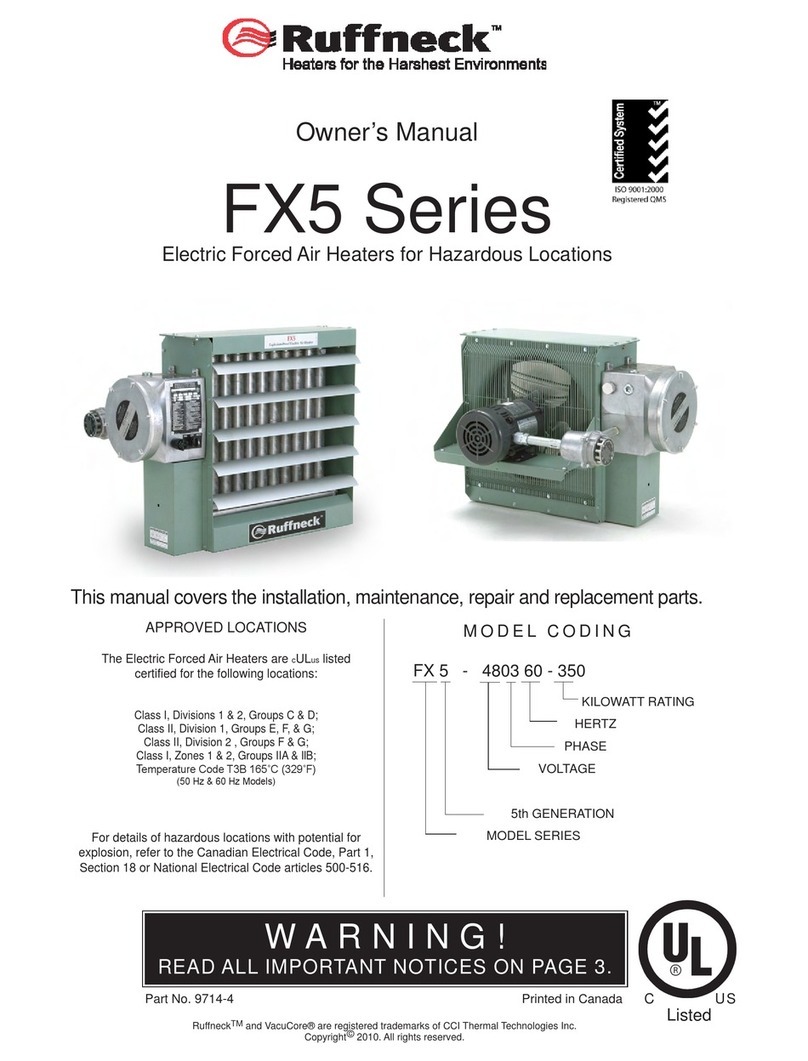

Refer to Section E. FX5 Technical Data, page 12

to 13 and heater data plate for conductor rating.

1.2 External overcurrent protection is required. Refer

to Section E. FX5 Technical Data, page 12 to

13 and heater data plate for voltage, frequency

amperage, and phase. Supply voltage is to be within

10% of the data plate voltage.

1.3 The heater must be installed by qualified personnel

in strict compliance with electrical codes.

1.4 All heaters come factory prewired and ready for direct

connection to the power supply leads.

1.5 The heater must be individually fused, preferably

with Class J time-delay fuses for maximum safety.

Unless stated otherwise in your local code, fuse size

shall be 125% of line current or next size larger.

2. Field Wiring

2.1 The supply conductors, ground conductor, and room

thermostat conductors (see D.3 Wiring Schematics,

page 11) all pass through the 1" NPT opening

(see Figure 6, page 9) and are to be wired into

the control enclosure (see Figure 7, page 9).

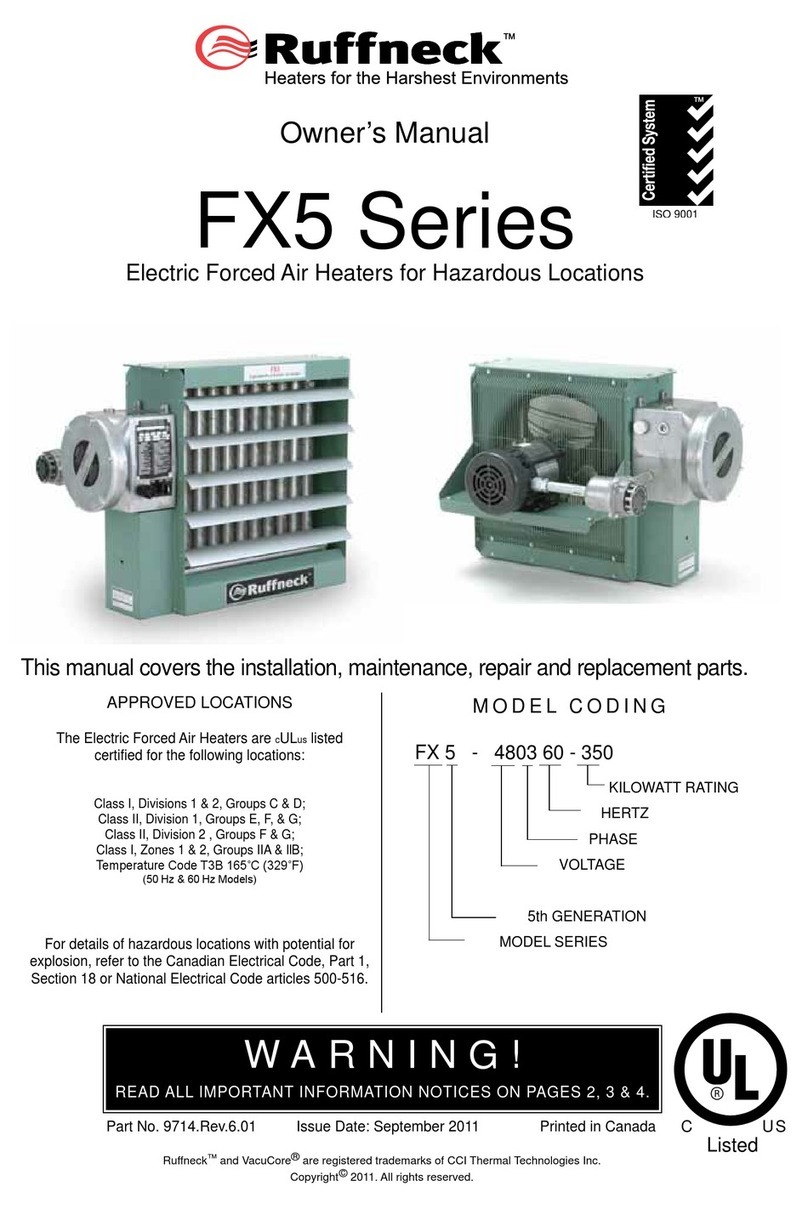

Rear View of Heater

Control enclosure

and cover

(Air exits through louvers)

1" NPT opening for field wiring Motor junction box

Air intake

Do not install conduit below heater. (See Figure 3)

Fan rotation

Figure 6

2.2 Heater may be supplied with a factory installed

built-in room thermostat (see Figure 8, page 10).

On heaters not supplied with this option, it is

recommended that a remote room thermostat

be used. Connect the remote room thermostat

conductors to the printed circuit board terminal

block marked “TSTAT”. Any thermostat used with

this heater must:

– Be of an explosion-proof type

– Be rated 125V minimum

– Have a minimum 2 amp capacity

– Open on temperature rise

2.3 Heater may be supplied with a factory installed built-in

integral disconnect. (See Figure 8, page 10)

Field Wiring for Integral Disconnect:

– Power Supply conductors and Ground

conductor pass through 1" NPT opening

of Disconnect Enclosure (see Figure 8,

page 10). Supply conductors to be wired to

Disconnect Switch inside. Ground conductor

to be wired to Ground Lug fastened to inside of

Disconnect Enclosure.

– If applicable, Remote Room Thermostat

conductors pass through 1" NPT opening (see

Figure 8, page 10) and are to be wired to

printed circuit board terminals marked “T’STAT”.

– To reduce risk of ignition of hazardous

atmospheres, conduit runs must have a sealing

fitting connected within 18" (457 mm).

2.4 Factory installed conduits require no further sealing.

Integral Disconnect is sealed at factory.

– The internal grounding terminal in the control

enclosure (or in the integral disconnect

enclosure when this option is provided) shall

be used as the equipment grounding means.

An external bonding terminal is provided for a

supplementary bonding connection where local

authorities permit or require such a connection.

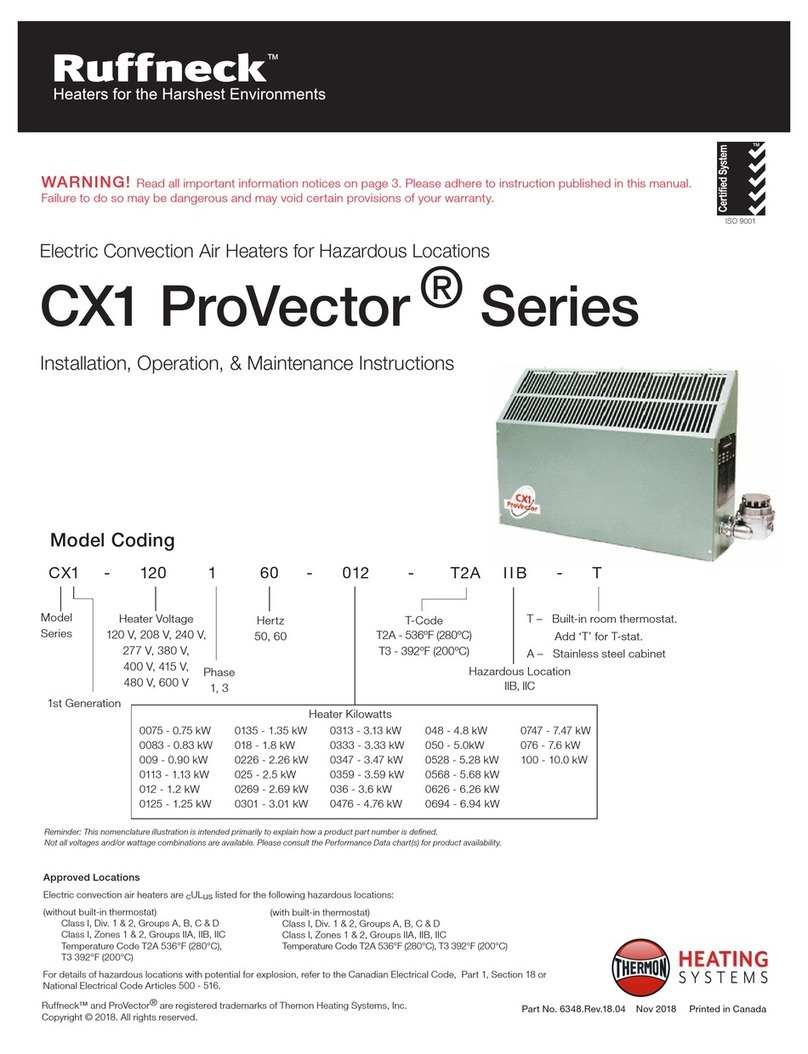

Control Enclosure & Field Wiring

Connect supply conductors

to this side of contactor.

Contactor load

side terminals, this

side for factory

wiring only.

Active and

spare fuses

(see Section

H. Parts List,

page 17)

Printed circuit board

Figure 7

99

Installation