8

Operation, Repair & Replacement

C. OPERATION

C.1 General

1. To operate heater, ensure power supply is properly

connected as specied in the wiring schematic (refer to

Figures 2A–2F, page5–7).

2. If unit is equipped with an optional thermostat, ensure the

thermostat is set above the ambient temperature.

3. If unit is equipped with the optional “fan only” switch, ensure

the switch is in the “ON” position. Note: If the switch is in

the “FAN ONLY” position, only the fan will energize, not the

heating elements.

4. During normal operation, the thermal cut-out control should not

cycle the heater ON and OFF. If cycling occurs, check to see

if there is an airow blockage. If there are no obstructions, the

heater must be examined by qualied personnel to determine

the cause of the thermal cut-out cycling.

5. Operate the unit for a minimum of 10 minutes to allow the

heating elements to reach a steady state. If no warm air is

discharged from the heater, shut off the unit and see the

Section F. Troubleshooting Tips, page 11.

D. REPAIR & REPLACEMENT

WARNING

WARNING. Disconnect heater from power supply at

disconnect or fuse box before opening enclosures or

servicing heater.

Lock the switch in the “OFF” (open) position and tag

the switch to prevent unexpected power application.

This heater should only be serviced by qualied

personnel with electrical heating equipment experience.

Install and use the heater in accordance with local

codes and this manual.

NOTE: ONLY USE FACTORY SUPPLIED REPLACEMENT PARTS

OF THE SAME SPECIFICATION. REFER TO TABLE 3 – PARTS LIST:

HEATING ELEMENTS, PAGE10 FOR COMPLETE LISTING OF

AVAILABLE PARTS.

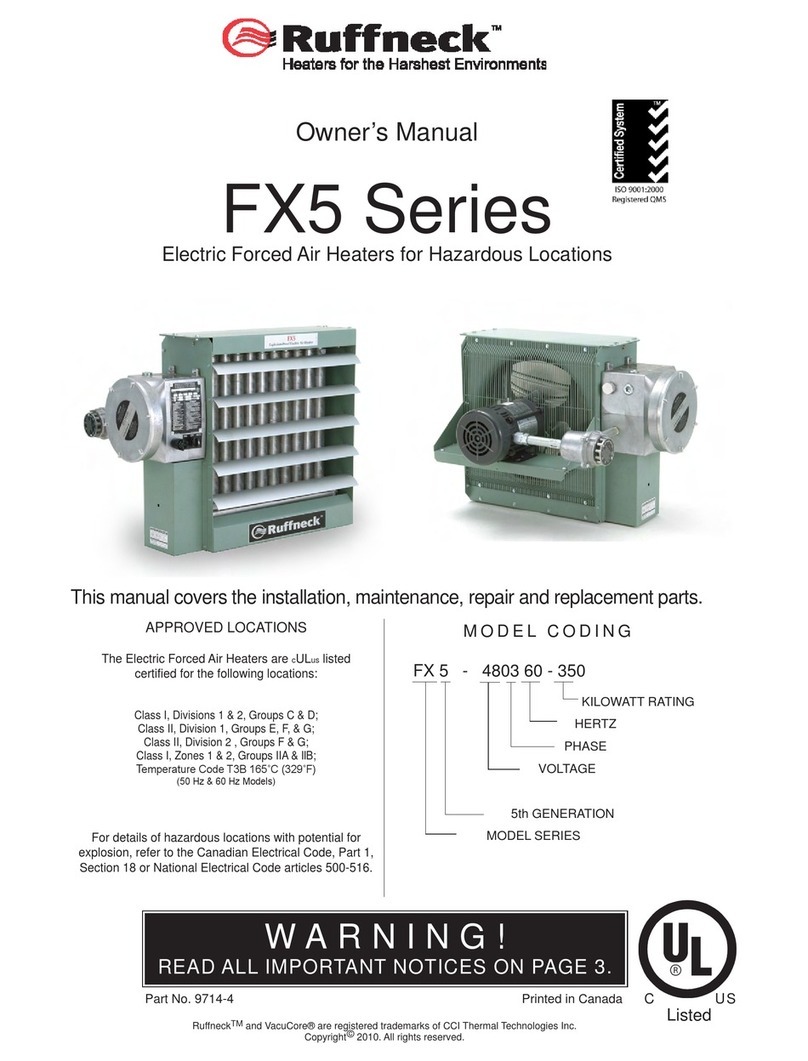

D.1 Heating Elements

1. Disconnect all wires connected to the heating element

terminals. Remove louver assembly from heater. Remove

heating elements, noting their proper placement.

2. Install factory-supplied replacement heating element (see

Table 3 – Parts List: Heating Elements, page10).

2.1 Ensure heating element attaching screws are in good

condition.

2.2 Re-attach heating element mounting screws and

tighten.

2.3 Check heating elements are not in contact with the

cabinet or each other.

3. Reinstall all wires with hardware provided. Torque the

element terminal hardware to the torque specications,

refer to Table 5 – Recommended Torque Specications,

page12.

4. Reinstall the louvers.

D.2 Fan

1. Remove the rear grille. Remove the screw securing the fan

to the fan hub attached to the motor.

2. Replace fan with factory-supplied fan. Install the fan such

that the “spider” of the fan faces the inside of the heater, i.e.

facing towards the elements.

D.3 Thermal Cut-Out

1. Disconnect all wires connected to thermal cut-out.

2. Remove two mounting screws.

3. Remove thermal cut-out switch from the enclosure.

4. Replace thermal cut-out with factory-supplied replacement

thermal cut-out.

5. Reinstall thermal cut-out switch in the control enclosure.

6. Re-attach thermal cut-out mounting screws.

7. Reconnect all wires to thermal cut-out.

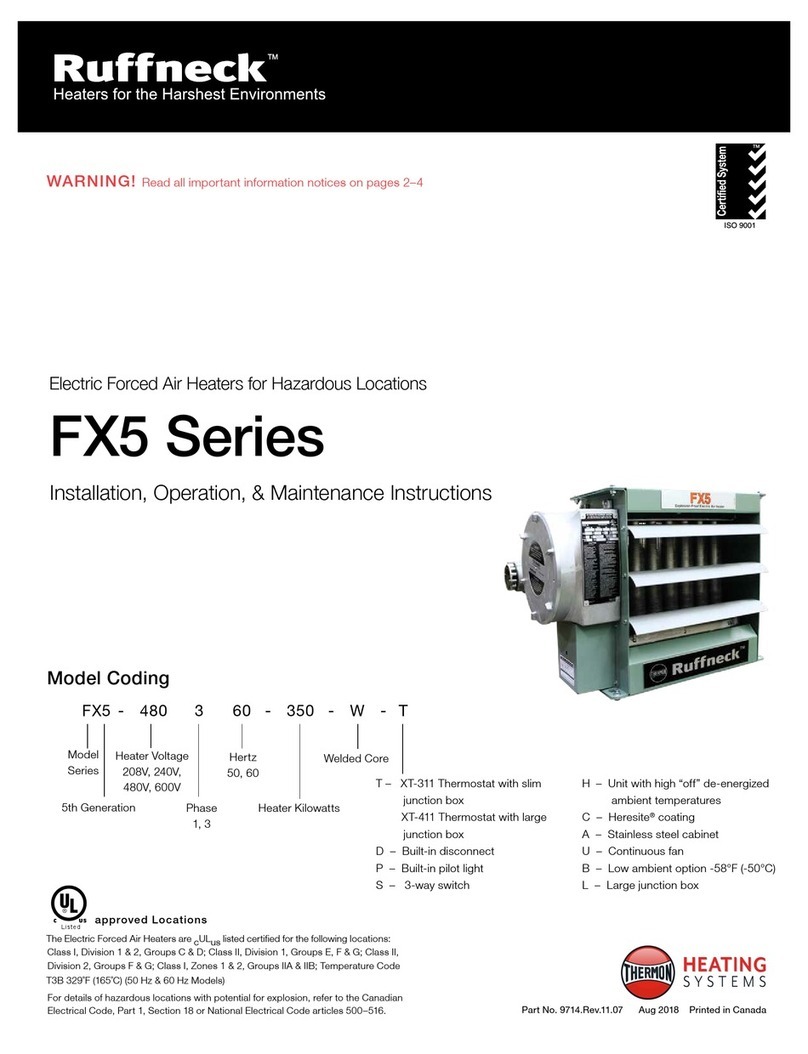

HEATER

CABINET

PANEL

ELEMENT

TERMINAL

HARDWARE

ELEMENT

MOUNTING

HARDWARE

HEATING ELEMENT

Figure 3 – Heating Element Assembly