7

Installation

7. Piping Applications

7.1 For steam service use only single-pass heaters.

Refer to Section D, page10 for tube-side pass

designation.

7.2 Refer to Figure4 and Figure5, page25, and

Figure6, page25 for typical piping applications.

7.3 To prevent condensate from entering the heater,

slope steam supply lines toward the steam main. In

long supply lines, drip traps may be needed.

7.4 For steam systems, use properly sized continuously

draining steam traps, such as oat or thermostatic

types. Traps must be sized to handle start up and

operational ows.

7.5 If the condensate return main is above the heater

outlet or is pressurized, install a check valve after the

steam trap and a drain valve at the strainer to drain

the system during the off season.

7.6 Allow for efcient condensate drainage and

subcooling by maintaining the outlet pipe size

between the heater and steam trap. Provide at least

a 10in (254mm) drop leg at condensate outlet.

7.7 In horizontal steam and condensate lines use

eccentric reducers only.

7.8 Allow for pipe expansion.

7.9 Eliminate pipe stress by adequately supporting all

piping. Do not rely on heater to support piping.

7.10 All piping must be properly sized for expected

ow rates.

7.11 For more piping information, consult industrial piping

handbooks.

7.12 Comply with all applicable piping codes.

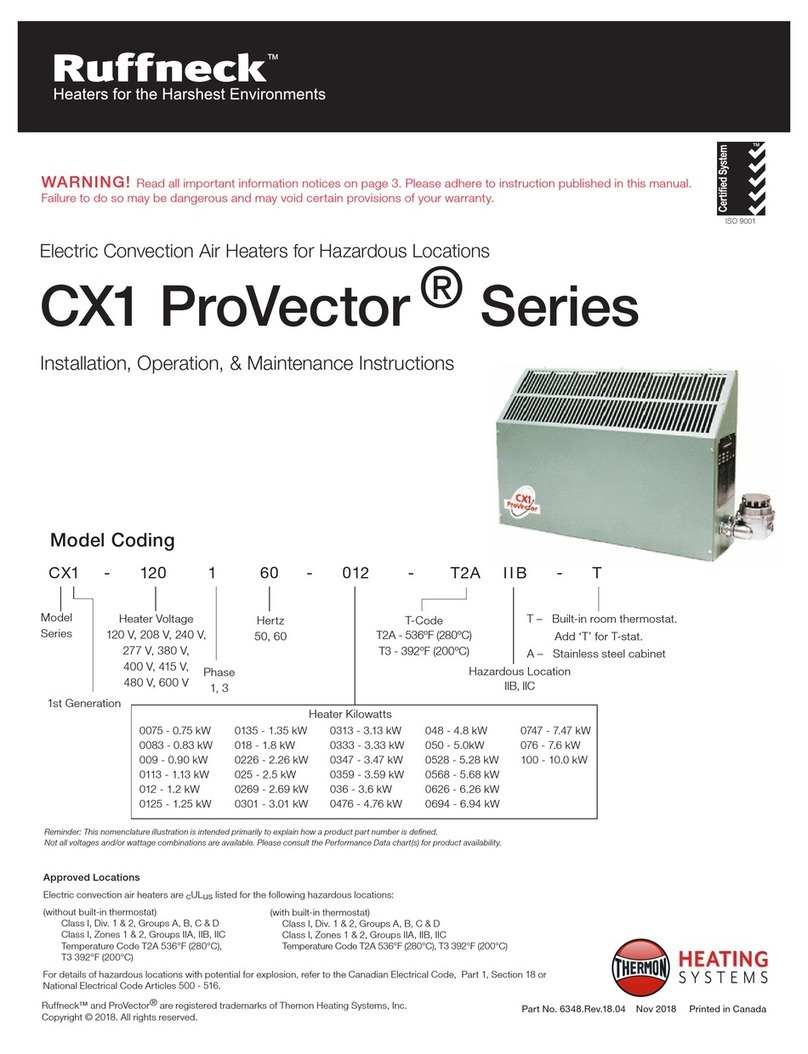

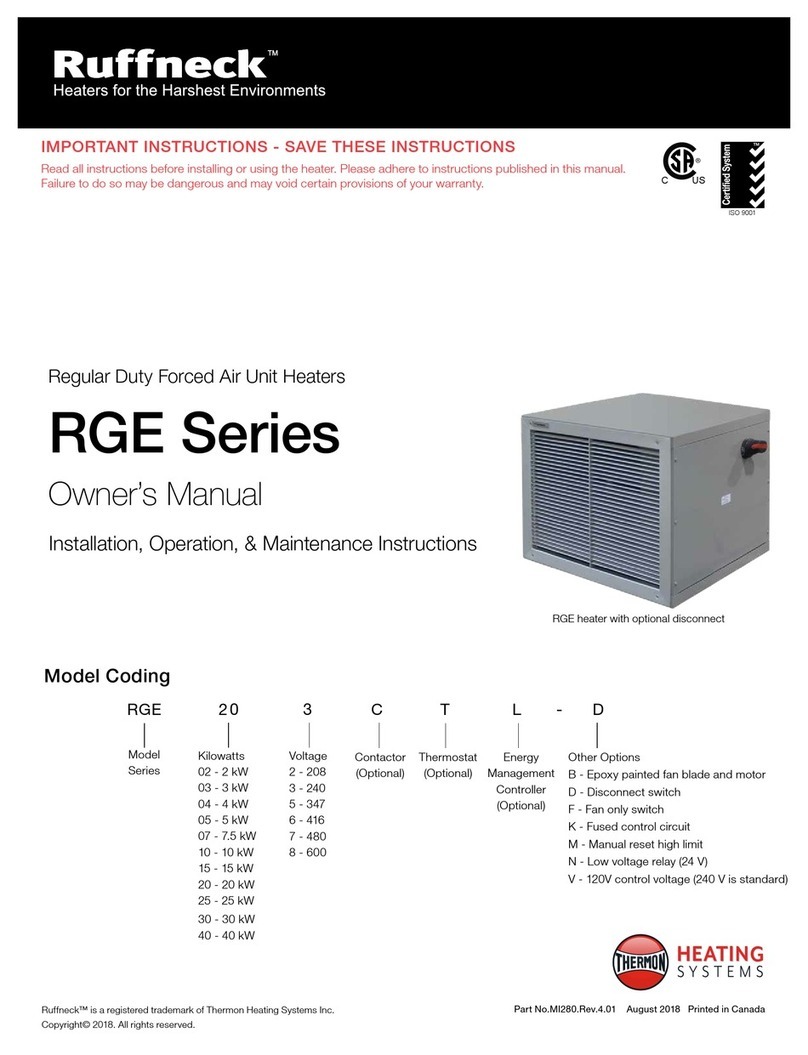

PIPING APPLICATIONS

1. For steam service use only single-pass heaters.

Refer to Model Coding Section for tube-side pass

designation.

2. Refer to figures 4-6 for typical piping applications.

3. To prevent condensate from entering the heater, slope

steam supply lines toward the steam main. In long

supply lines, drip traps may be needed.

4. For steam systems, use properly sized continuously

draining steam traps, such as float or thermostatic

types. Traps must be sized to handle start up and

operational flows.

5. If the condensate return main is above the heater

outlet or is pressurized, install a check valve after the

steam trap and a drain valve at the strainer to drain

the system during the off season.

6. Allow for efficient condensate drainage and sub-

cooling by maintaining the outlet pipe size between

the heater and steam trap. Provide at least a 10 inch

(254 mm) drop leg at condensate outlet.

7. In horizontal steam and condensate lines use

eccentric reducers only.

8. Allow for pipe expansion.

9. Eliminate pipe stress by adequately supporting all

piping. Do not rely on heater to support piping.

10. All piping must be properly sized for expected flow

rates.

11. For more piping information, consult industrial piping

handbooks.

12. Comply with all applicable piping codes.

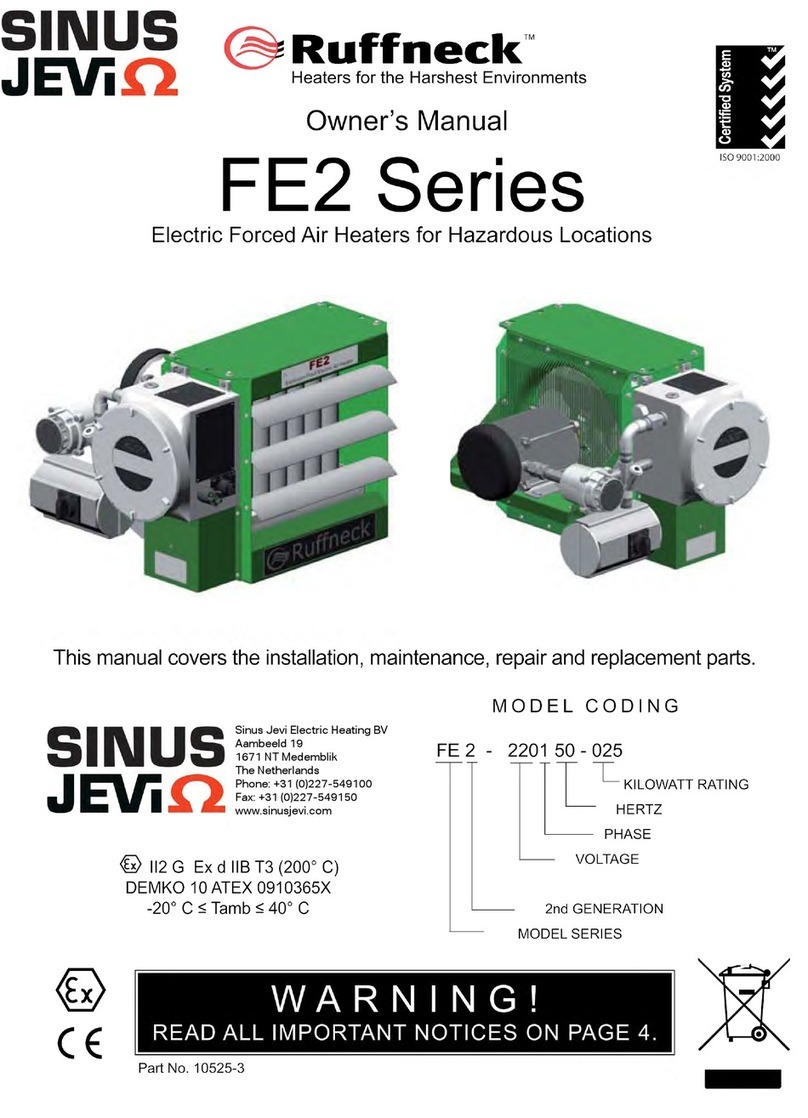

Unit heater connection for

low-pressure steam,

open gravity or vacuum return system.

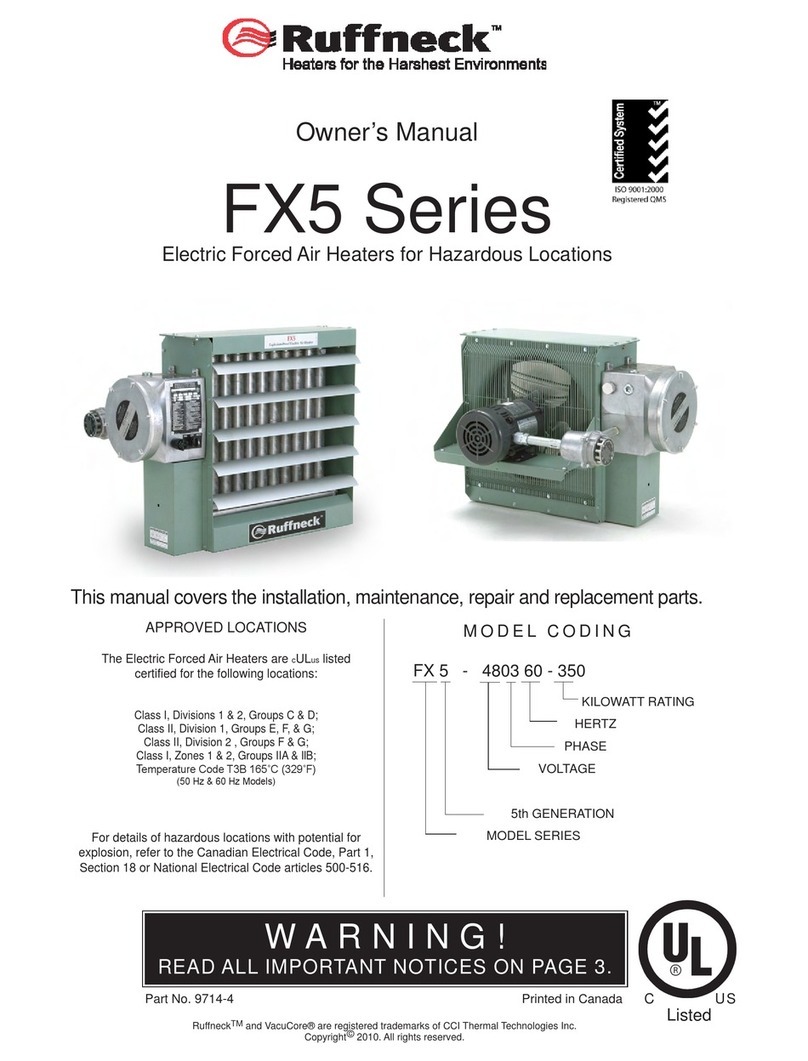

Unit heater connections to overhead steam

and return mains.

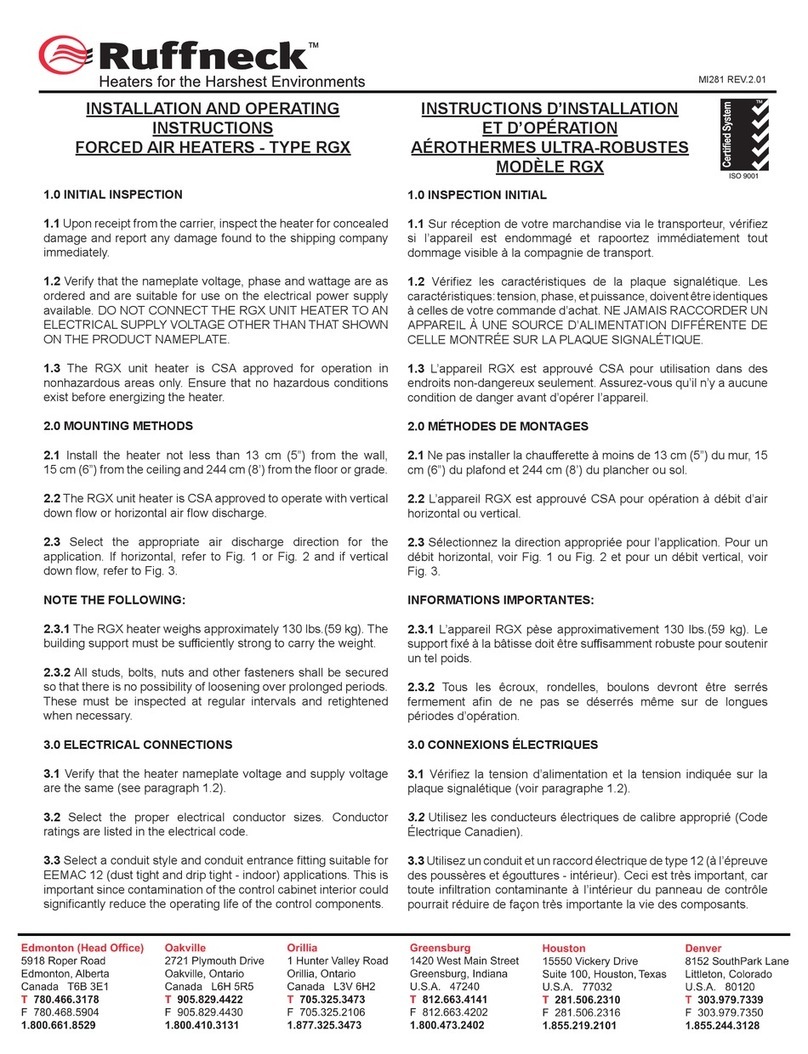

Unit heater connections to

overhead liquid mains

FIGURE 4

FIGURE 5 FIGURE 6

NOTES: 1. This piping arrangement is only for two-position-type control.

Modulating steam control may not provide su ressure to

lift condensate to return main.

2. rosive to steel.

3. Install using proper piping practices.

4. In horizontal pipe runs, use eccentric reducers only.

5. Use a properly sized steam trap.

NOTES: 1. For medium to high pressur

must be used.

2. rosive to steel.

3. Install using proper piping practices.

4. In horizontal pipe runs, use eccentric reducers only.

5. Use a properly sized steam trap.

NOTES: 1. rosive to steel.

2. Install using proper piping practices.

Figure4

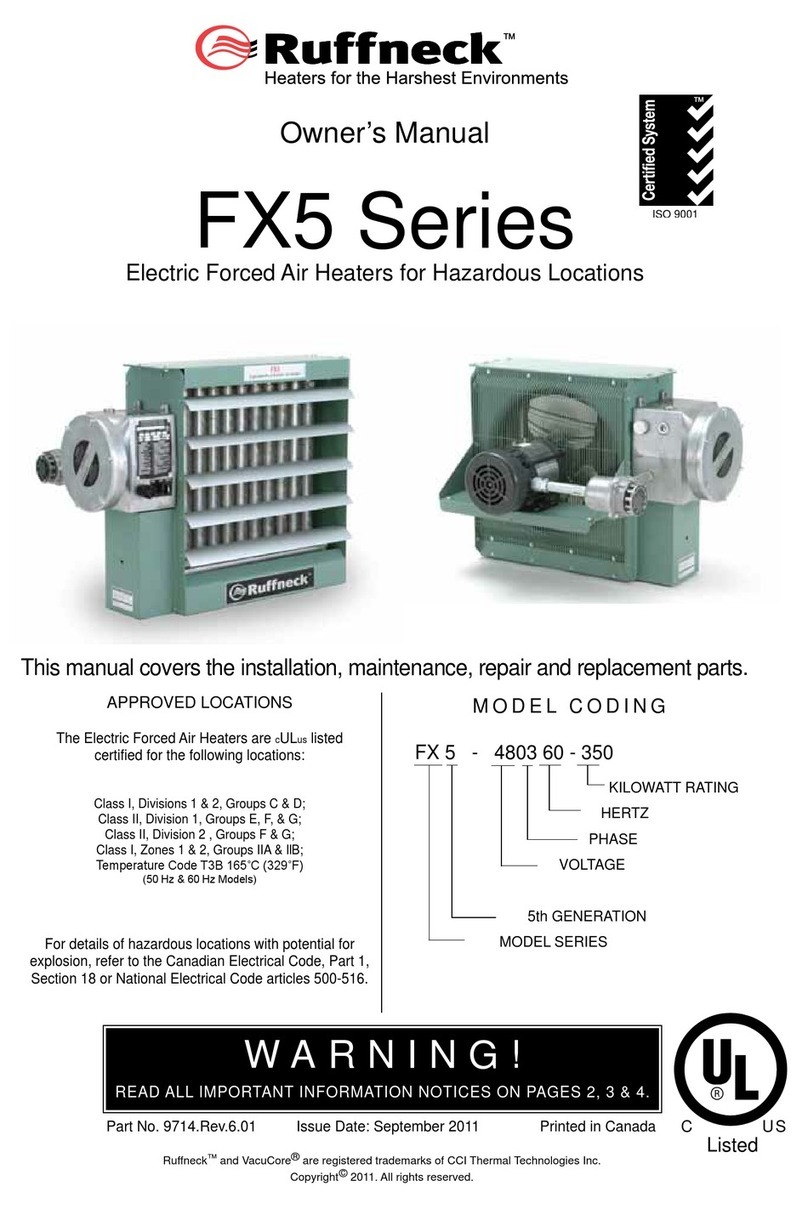

PIPING APPLICATIONS

1. For steam service use only single-pass heaters.

Refer to Model Coding Section for tube-side pass

designation.

2. Refer to figures 4-6 for typical piping applications.

3. To prevent condensate from entering the heater, slope

steam supply lines toward the steam main. In long

supply lines, drip traps may be needed.

4. For steam systems, use properly sized continuously

draining steam traps, such as float or thermostatic

types. Traps must be sized to handle start up and

operational flows.

5. If the condensate return main is above the heater

outlet or is pressurized, install a check valve after the

steam trap and a drain valve at the strainer to drain

the system during the off season.

6. Allow for efficient condensate drainage and sub-

cooling by maintaining the outlet pipe size between

the heater and steam trap. Provide at least a 10 inch

(254 mm) drop leg at condensate outlet.

7. In horizontal steam and condensate lines use

eccentric reducers only.

8. Allow for pipe expansion.

9. Eliminate pipe stress by adequately supporting all

piping. Do not rely on heater to support piping.

10. All piping must be properly sized for expected flow

rates.

11. For more piping information, consult industrial piping

handbooks.

12. Comply with all applicable piping codes.

Unit heater connection for

low-pressure steam,

open gravity or vacuum return system.

Unit heater connections to overhead steam

and return mains.

Unit heater connections to

overhead liquid mains

FIGURE 4

FIGURE 5 FIGURE 6

NOTES: 1. This piping arrangement is only for two-position-type control.

Modulating steam control may not provide su ressure to

lift condensate to return main.

2. rosive to steel.

3. Install using proper piping practices.

4. In horizontal pipe runs, use eccentric reducers only.

5. Use a properly sized steam trap.

NOTES: 1. For medium to high pressur

must be used.

2. rosive to steel.

3. Install using proper piping practices.

4. In horizontal pipe runs, use eccentric reducers only.

5. Use a properly sized steam trap.

NOTES: 1. rosive to steel.

2. Install using proper piping practices.

Figure5

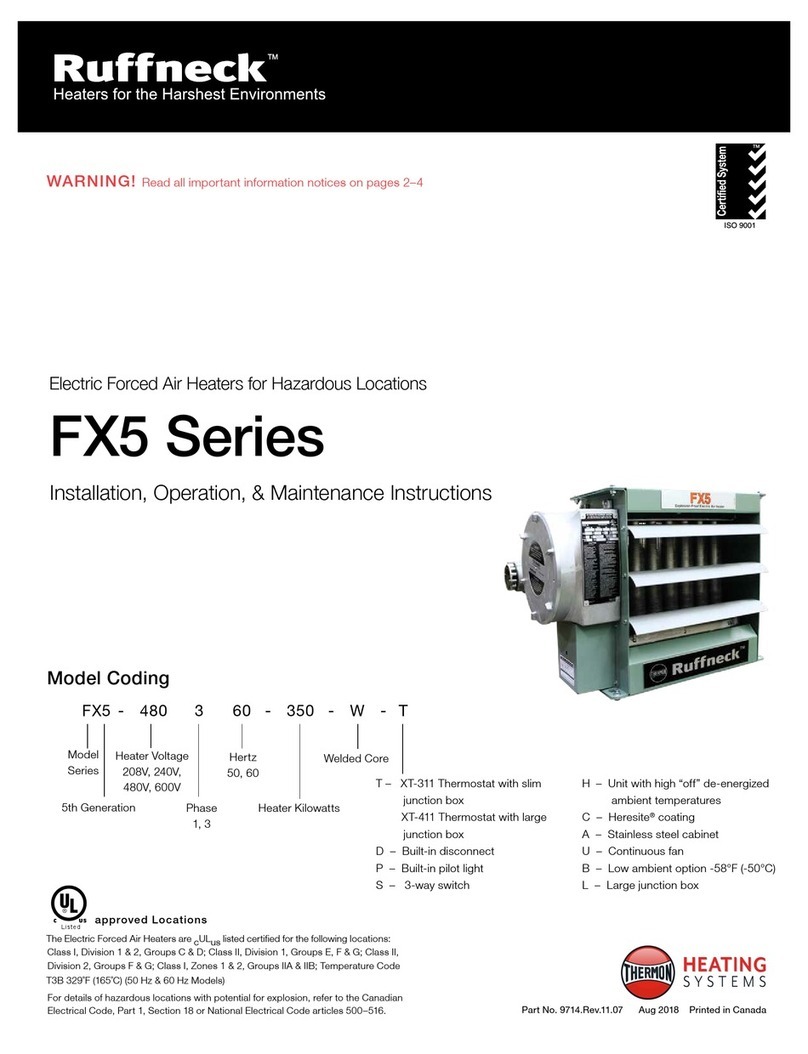

PIPING APPLICATIONS

1. For steam service use only single-pass heaters.

Refer to Model Coding Section for tube-side pass

designation.

2. Refer to figures 4-6 for typical piping applications.

3. To prevent condensate from entering the heater, slope

steam supply lines toward the steam main. In long

supply lines, drip traps may be needed.

4. For steam systems, use properly sized continuously

draining steam traps, such as float or thermostatic

types. Traps must be sized to handle start up and

operational flows.

5. If the condensate return main is above the heater

outlet or is pressurized, install a check valve after the

steam trap and a drain valve at the strainer to drain

the system during the off season.

6. Allow for efficient condensate drainage and sub-

cooling by maintaining the outlet pipe size between

the heater and steam trap. Provide at least a 10 inch

(254 mm) drop leg at condensate outlet.

7. In horizontal steam and condensate lines use

eccentric reducers only.

8. Allow for pipe expansion.

9. Eliminate pipe stress by adequately supporting all

piping. Do not rely on heater to support piping.

10. All piping must be properly sized for expected flow

rates.

11. For more piping information, consult industrial piping

handbooks.

12. Comply with all applicable piping codes.

Unit heater connection for

low-pressure steam,

open gravity or vacuum return system.

Unit heater connections to overhead steam

and return mains.

Unit heater connections to

overhead liquid mains

FIGURE 4

FIGURE 5 FIGURE 6

NOTES: 1. This piping arrangement is only for two-position-type control.

Modulating steam control may not provide su ressure to

lift condensate to return main.

2. rosive to steel.

3. Install using proper piping practices.

4. In horizontal pipe runs, use eccentric reducers only.

5. Use a properly sized steam trap.

NOTES: 1. For medium to high pressur

must be used.

2. rosive to steel.

3. Install using proper piping practices.

4. In horizontal pipe runs, use eccentric reducers only.

5. Use a properly sized steam trap.

NOTES: 1. rosive to steel.

2. Install using proper piping practices.

Figure6