4

4

Important Notices / Installation

B. IMPORTANT NOTICES

WARNING

WARNING. Read and adhere to the following

installation instructions. FAILURE TO DO SO MAY

RESULT IN SEVERE OR FATAL INJURY AND/OR

POSSIBLE VOIDING OF THE WARRANTY.

1. Read and follow all instructions in this manual.

2. Heater is to be used only in atmospheres having an

ignition temperature higher than the heater’s maximum

rated operating temperature, as shown on the heater data

plate. Refer to applicable electrical codes for additional

information.

3. Heater to be used only in the hazardous locations

indicated on the heater data plate.

4. Heater is for dry, indoor use only. Do not immerse in water.

Do not store or use in areas exposed to rain or snow.

5. Maximum ambient operating temperature 104°F (40°C).

6. Heater is to be connected and serviced only by a qualied

electrician experienced with hazardous location equipment.

7. Installation and wiring of the heater must adhere to all

applicable codes.

8. Before opening any enclosures, disconnect the

heater from the power supply. Lock the switch in the

“OFF” (open) position and/or tag the switch to prevent

unexpected power application.

9. External surfaces get hot and can cause burns with

prolonged contact.

10. Operate the heater only while it is permanently mounted

in an upright position. Refer to the C.1 Mechanical,

page4 for details.

11. Heater must be kept clean. When operating in a dirty

environment, regularly clean the nned tubes, top vents,

and keep bottom opening free of obstructions. Follow the

recommended maintenance procedures. Refer Section A.

Heater Maintenance Checklist, page3 for details.

12. Do not operate the heater in atmosphere corrosive to steel

or aluminum.

13. Use factory approved replacement parts only.

14. Conduit seals are not required in the heater’s factory

installed conduits.

15. A conduit seal is required within 6" (153mm) of eldentries.

16. If there are any questions or concerns regarding the heater,

contact the factory. Refer to the last page of this manual

for details.

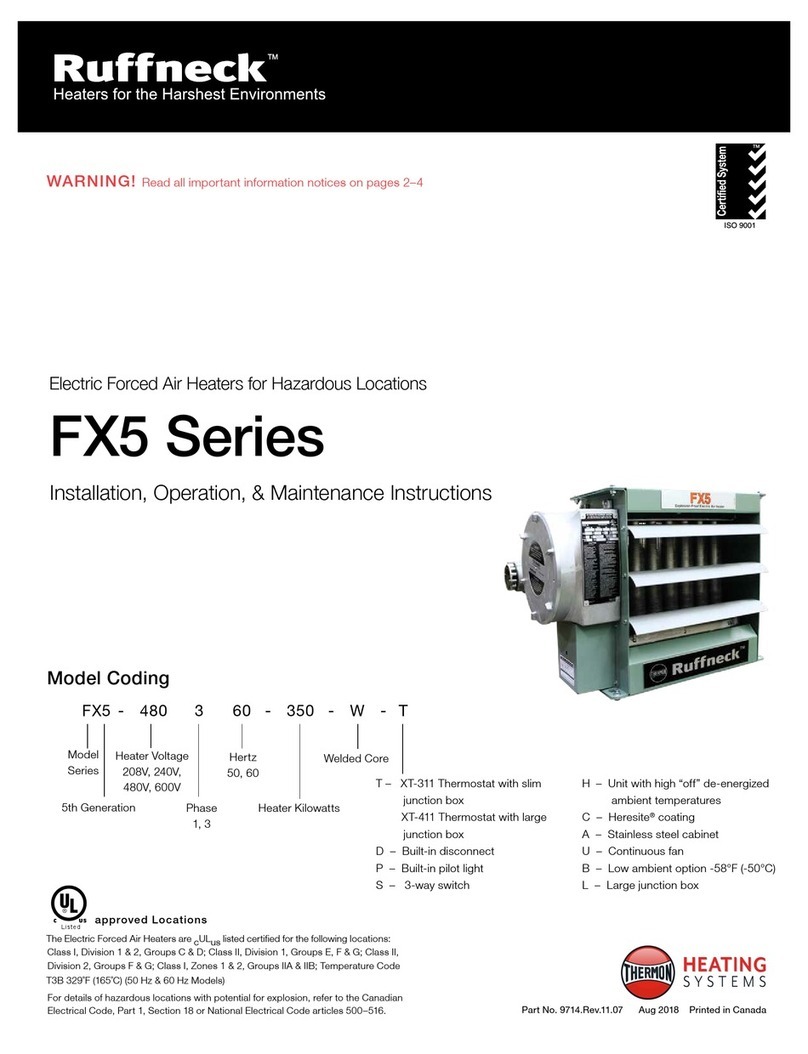

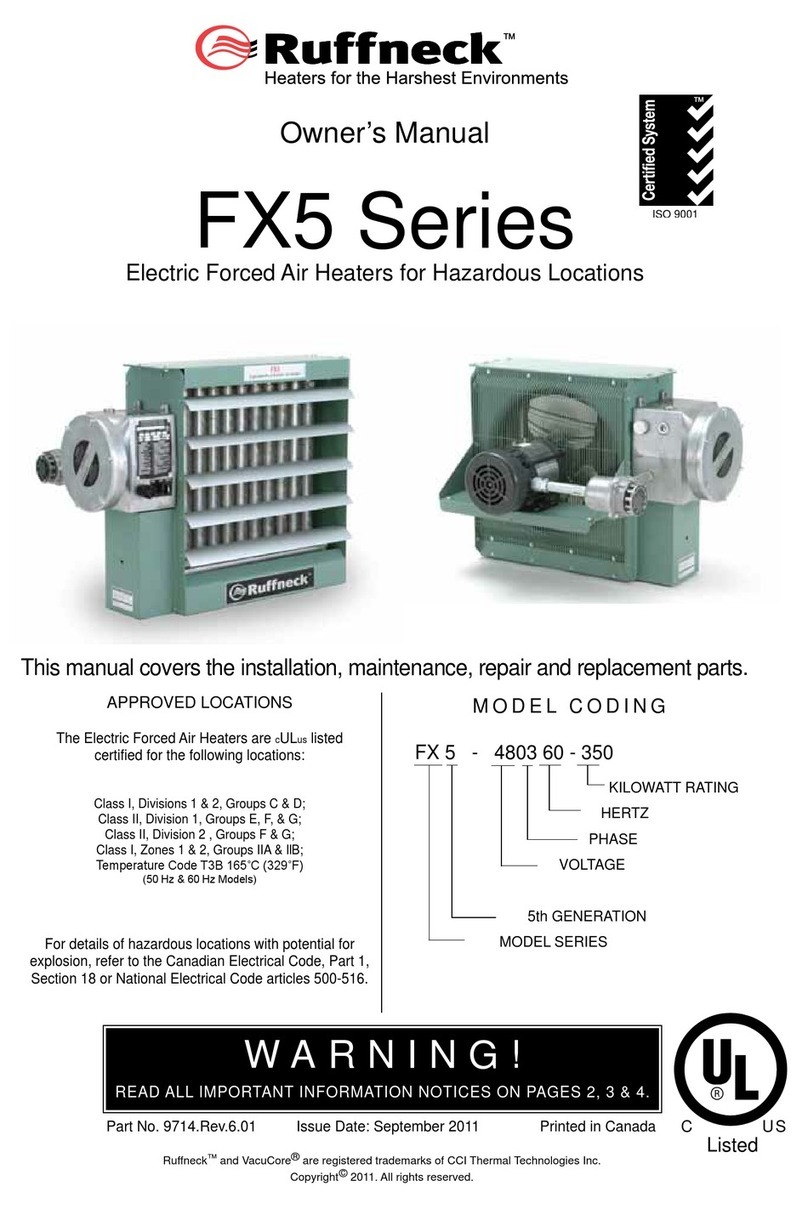

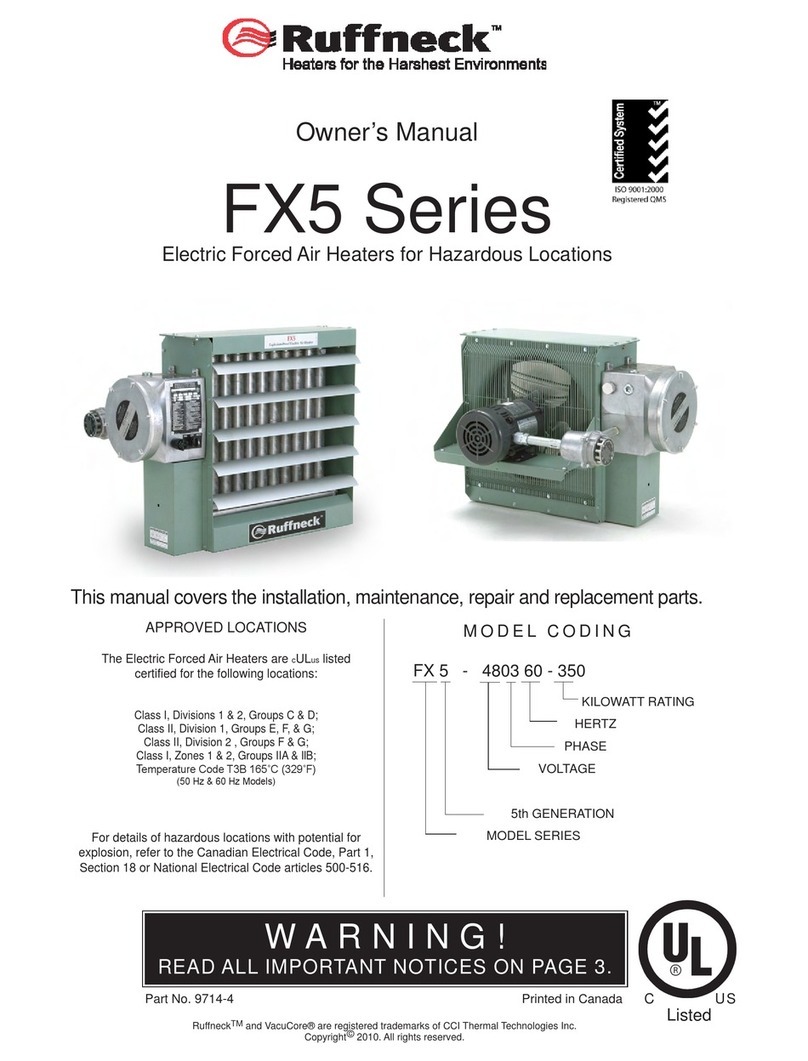

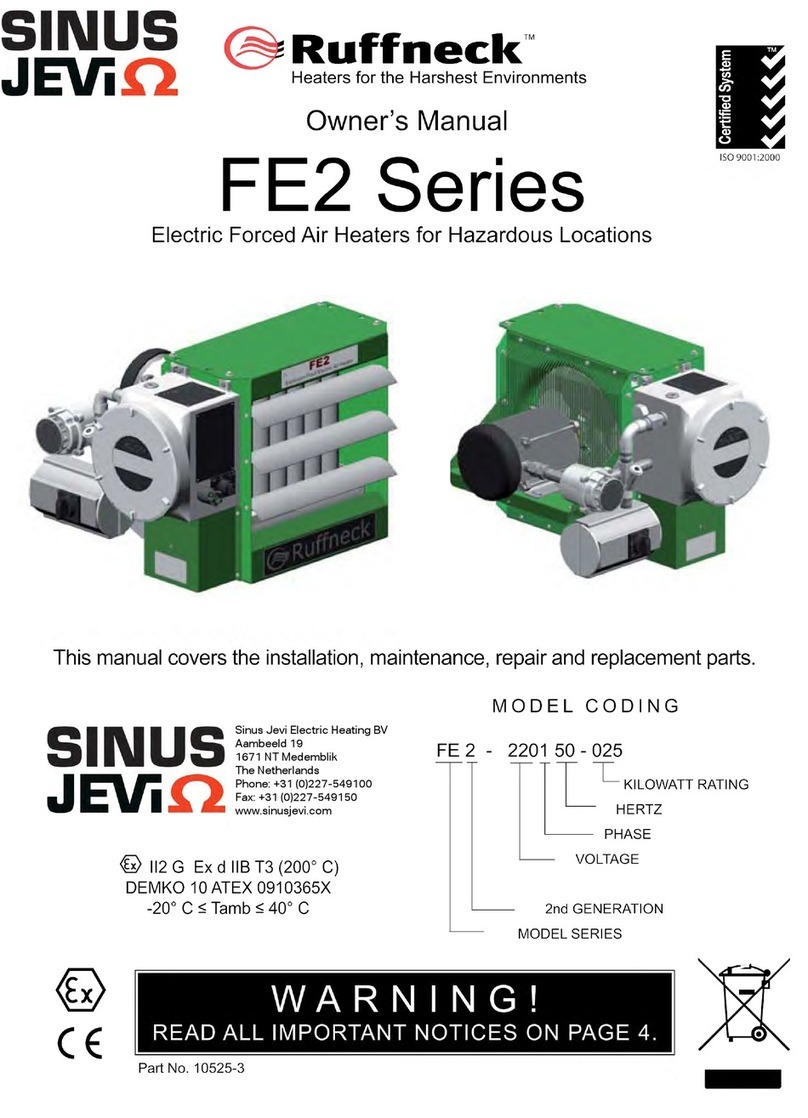

C. INSTALLATION

All applicable codes must be adhered to. For optimum heating, the

heater should be installed as follows:

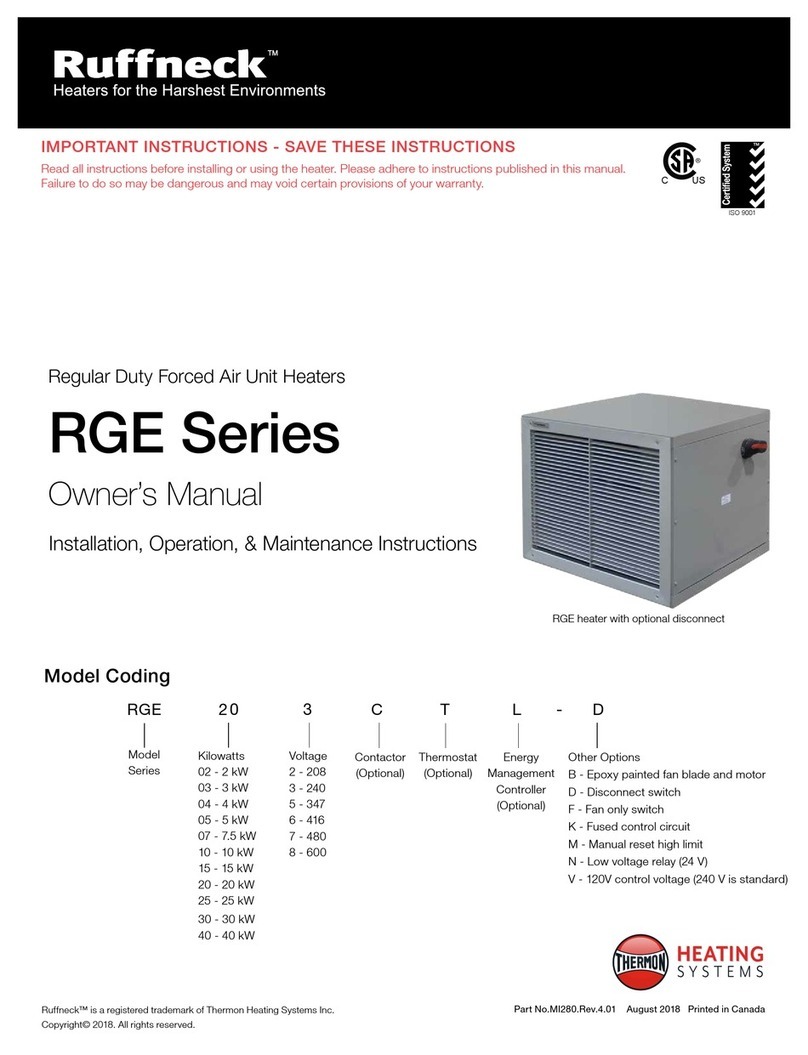

C.1 Mechanical

1. Location

1.1 The air discharge is not directed at a thermostat.

1.2 The air discharge is across areas of heat loss, such

as windows.

1.3 If equipment freeze protection is of importance,

locate heater as close to equipment as possible.

2. Mounting

2.1 Heater must be mounted level on a vertical surface

using the factory supplied mounting brackets such

that there are no obstructions to impede air inlet or

discharge.

2.2 The mounting surface must be strong enough to:

–Support the heater’s weight, refer to Section D.

Specications, page8.

–Withstand abusive situations such as transportable

installations of the heater.

2.3 Secure mounting brackets to vertical surface with the

top mounting hole 1.5" (38mm) below the desired top

surface height (Figure1, page4). Refer to Figure3,

page5, Figure4 and Figure5, page4 for physical

dimensions and Figure5, page6 for required

installation clearances. Mounting brackets are to be

spaced to match the slots in the rear panel of heater

cabinet.

2.4 After mounting brackets are secured, tilt the heater

and lower it onto the top tabs of the mounting

bracket such that the tabs go into the mounting

slots on the rear panel of the heater cabinet (Figure2,

page5).

1.5"

(38.0mm)

Figure1