WARNING: Installing or operating this hoist without first understanding the proper installation and operation

procedures can lead to serious injury or death. Always read and understand fully all installation

and operation manuals before installing or operating this equipment.

WARNING: Welding, oxy-fuel cutting, or grinding sparks can cause fuel to ignite that in turn can lead to injury

or death. Always take adequate steps to avoid ignition of fuel from fuel tanks when welding,

grinding, or oxy-fuel cutting during equipment installation.

WARNING: Heat from the truck's exhaust system can cause hydraulic component failure and may lead to a fire

that could cause injury or death. Always install equipment in locations where heat from the

exhaust system will not damage any hydraulic component.

WARNING: Being under a raised body can result in serious injury or death should the body unexpectedly

descend. Never position yourself or allow others to position themselves under a loaded body.

Always prop the unloaded body up using the body prop or body props supplied. Remember

body props are to be used only on an unloaded body. When two props are provided, both props

must be used.

WARNING: Malfunctioning equipment can cause property damage, injury or death. Always have faulty

equipment repaired before continuing its use. Consult the manufacturer if required.

WARNING: Overloading of a body can cause vehicle or body component damage or an accident which may

cause injury or death. Never exceed the gross vehicle weight (GVW) or the gross axle weight

(GAW) rating of your vehicle.

WARNING: The inadvertent shorting of the vehicle's electrical supply can cause a fire or equipment damage

that could lead to injury or death. Always disconnect the vehicle battery prior to installing,

servicing, or repairing the power unit.

WARNING: Damage to brake lines during equipment installation, or installing bolts or equipment in such a

way that the line will rub and become damaged can lead to brake failure which can cause an

accident and can lead to severe injury or death. Always take adequate steps to prevent brake line

damage during installation and isolate brake lines from installed equipment.

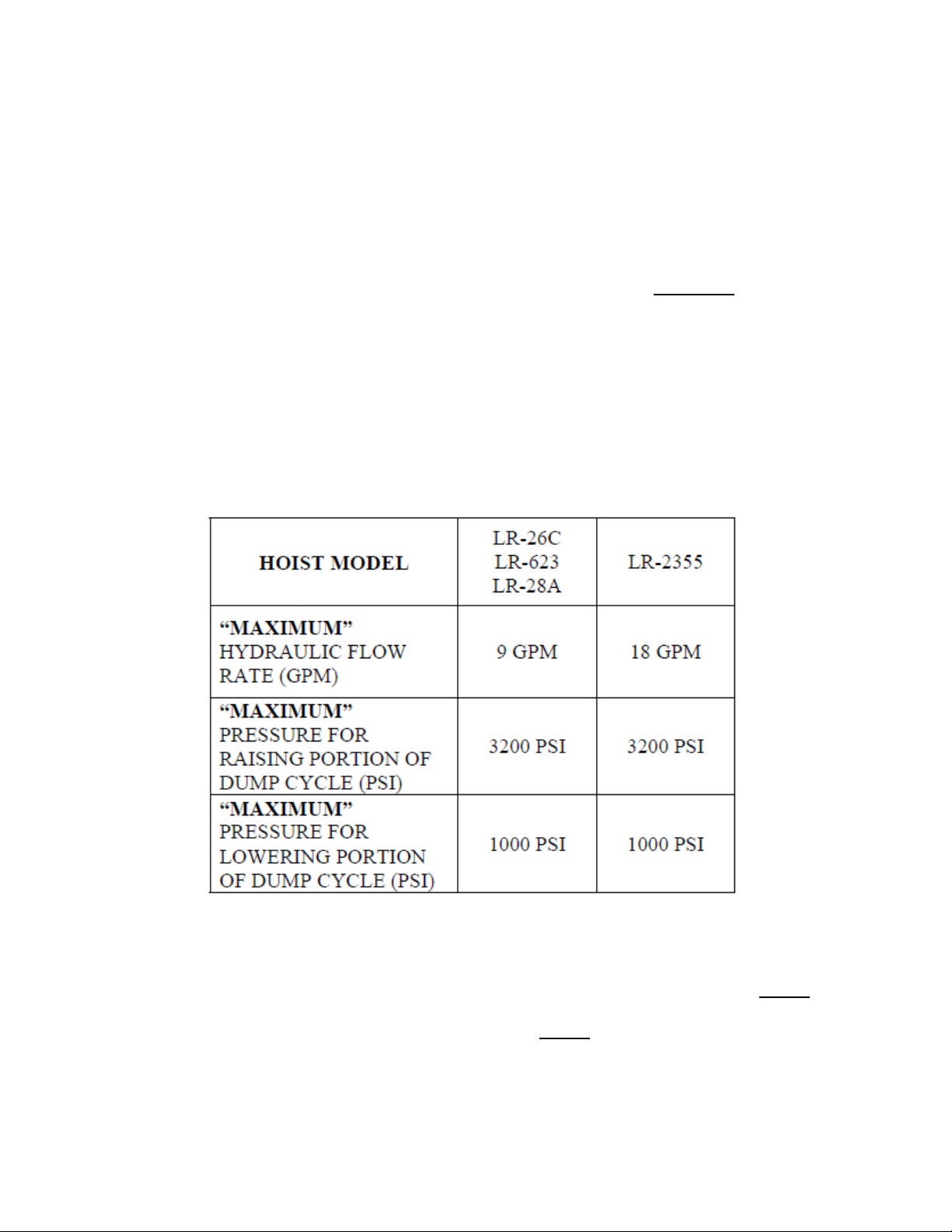

WARNING: Connecting the hoist to a hydraulic system with more pressure (psi) or flow (gpm) than is

recommended by the hoist manufacturer can cause the hoist to fail during the dumping of a load.

This could lead to damage, serious injury, or death. Be sure you have the correct pressure and

flow.