www.victorruoshui.co.kr

이자료는 저작권법에 따라 보호받는 저작물이므로 무단배포 및무단복제를 금하며, 내용을 이용하려면, 한국 VictorRuoshui 社

의서면동의를 받아야 합니다.

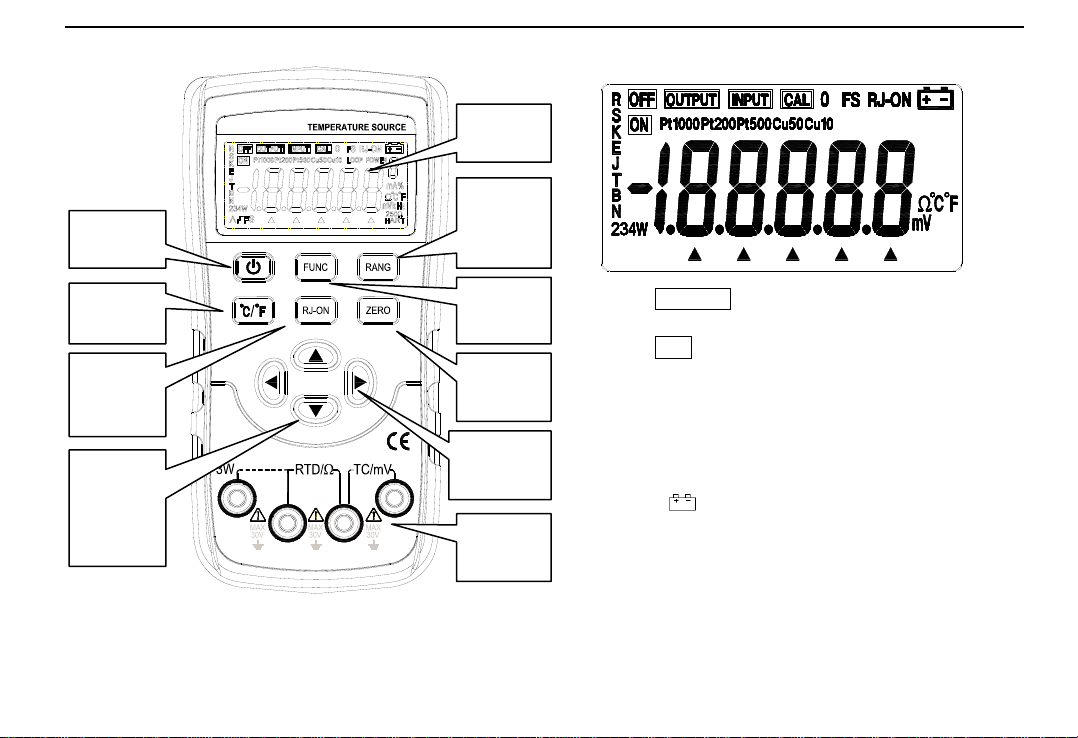

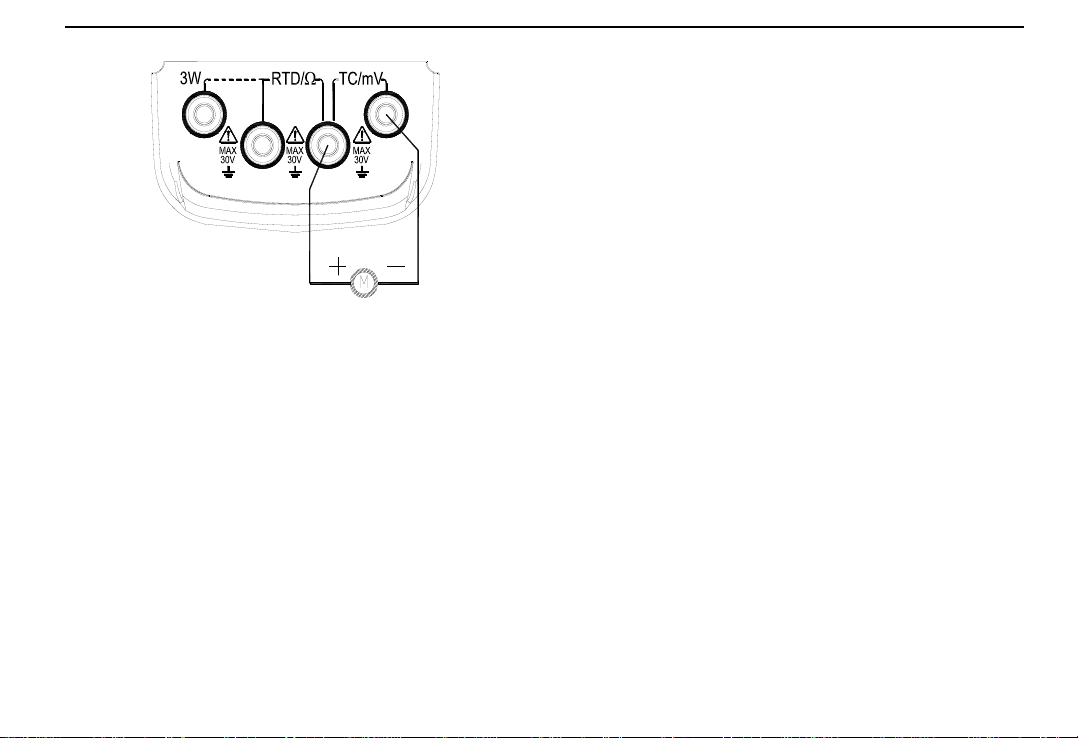

Figure 5-1

5. Press 〔〕/〔〕key , change the value of set bit,

and the value can carry or abdicate automatically,

and hold the key, the value will alter constantly after

one second.

6. Press the 〔ZERO〕key, the output will be set as

000.00mV or 0000.0mV.

(2) Thermocouple (TC )simulate output

1. Insert the testing probe into the jack of the meter‟s

output terminal (TC/mV), and connect the other end

with input terminal of the Users‟ meter, see Figure

5-1;

2. Press 〔FUN 〕key , select thermocouple(TC)

function, and display „C‟ unit and „R‟ graduation no.;

3. Press 〔RANG 〕key, select corresponding

graduation no.;

4. Press 〔〕/〔〕key, select output set bit;

5. Press 〔〕/〔〕key , change the value of set bit,

and the value can carry or abdicate automatically,

and hold the key, the value will change constantly

after one second.

6. Automatic compensation of cold junctions

When calibrating meter with temperature cold

junction compensation directly, press 〔RJ-ON〕key to

start the automatic compensation function of cold

junctions of this meter, and it will output the necessary

temperature thermoelectric force, and display „RJ-ON‟.

(See Section Seven for the accuracy of cold junction

compensation), and :

Output thermoelectric force = the corresponding

thermoelectric force of set temperature –the

corresponding thermoelectric force of room temperature

* The Users need to wait for 2 seconds when

starting the interior cold junction compensation of

the meter and the meter will make automatic

compensation every 10 seconds

* When the operation ambient temperature change,

the Users need to wait until the interior

compensation sensor stabilizes (about 10 minutes)

and then use

* If the Users do not use the automatic compensation

function of this meter, press the〔RJ-ON〕key and

the symbol‘RJ-ON’will not display any more

7. Press〔ZERO〕key, the output will be set as 0000C

(R, S graduation), 400C(B graduation),