INSTALLATION

Thermostatic mixing valves are temperature sensitive appliances so must not

be subjected to extreme temperatures (either hot or cold) in use or

installation.

BRAZING OR SOLDERING ON OR NEAR THE MAIN VALVE BODY MUST BE

AVOIDED.

The valves should be fitted where they can be easily accessed for

commissioning and maintenance.

Offer up the valve to the system and mark out where the valve is to be fitted.

With the smaller of the provided Allen keys loosen the grub screws securing

the fixing ring to the back of the valve and remove it.

Mark out, drill and rawplug the fixing holes and secure the fixing ring to the

wall (the mounting surface must be strong enough to take the weight of the

valve).

Fit the valve to the fixing ring and tighten the grub screws evenly.

COMMISSIONING

The Euromixer thermostatic mixing valve is supplied factory set at 41°C with

2 bar equal pressures in a non adjustable form. There are three forms in which

this valve can be commissioned:

1. It can be commissioned at any fixed non-adjustable temperature

between 35°C and 50°C.

2. It can be commissioned in an adjustable form with a set maximum

temperature.

3. It can be commissioned in an adjustable form with no preset

maximum temperature.

General

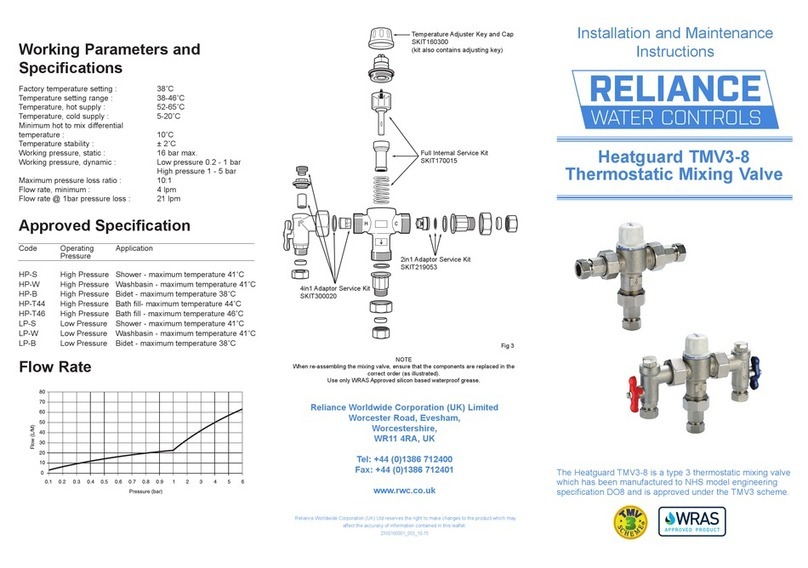

Ensure that both water supplies are turned on and that the hot water

temperature is 55-60°C minimum. Check that the dynamic water pressure on

both hot and cold supplies is within the working parameters of the valve at

the installations maximum and minimum flow rates. If the hot cold and cold

water pressure differential is greater than 2 : 1 then pressure reducing valves

may be required.

w rate

TROUBLE SHOOTING

I CAN ONLY GET HOT OR COLD WATER FROM THE OUTLET?

• Checkthatthevalveisconnectedupcorrectly,withthehot

and cold supplies connected the corresponding fittings on

the valve.

• Checkthatthesuppliesarebothworkingcorrectly.

• Checknon-returnvalvesandstrainersininletfittingsfor

blockages and clean if necessary.

• Checkthatsupplyconditionsarewithinthosestatedinthe

working parameters at the beginning of this booklet.

I AM GETTING FLUCTUATING MIXED OUTLET TEMPERATURE?

• Debrisisfoulingthevalvecausingittobecomesluggish.

Service valve as per maintenance instructions.

• Checknon-returnvalvesandstrainersininletfittingsfor

blockages and clean if necessary.

I AM GETTING FLUCTUATING AND/OR POOR FLOW RATES?

• Checknon-returnvalvesandstrainersininletfittingsfor

blockages and clean if necessary.

• Checkisolationvalvesarefullyopen.

• Checkthatsupplyconditionsarewithinthosestatedinthe

working parameters at the beginning of this booklet.

I AM GETTING CROSS FLOW OF HOT WATER INTO THE COLD WATER

SUPPLY OR VICE VERSA?

• Checknon-returnvalvesandstrainersininletfittingsfor

blockages and clean if necessary.

• Checkthatsupplyconditionsarewithinthosestatedinthe

working parameters at the beginning of this booklet.

THE VALVE WILL NOT SHUT DOWN?

• Checkthatthehotsupplytomixtemperaturedifferential

is a minimum of that stated in the working parameters.

• Debrisisfoulingthevalvecausingittostick.Servicevalve

as per maintenance instructions.