15 16

bracket using the 5 mm hex key (supplied).

3. Reposition the riving knife (3) left or right, as required in order

aligning the riving knife (3) with the saw blade.

4. Once properly aligned, securely retighten the socket head bolts

(36).

WARNING: The riving kinfe must always be correctly aligned so

that the cut workpiece will pass on either side of the riving knife

without binding or twisting to the side.

WARNING: Improper riving knife alignment can cause kickback

and serious injury.

ADJUSTING THE BEVEL STOPS (FIG. 6-1, 6-2 & 6-3)

This saw has positive stops that will quickly position the saw blade

at 90° or 45° to the table.

The angle settings of the saw have been set at the factory and,

unless damaged in shipping, should not require setting during

assembly. After extensive use, it may need to be checked. Make

adjustments only if necessary.

1. Unplug the saw.

2. Raise the blade to the maximum height by turning the high

adjusting handle clockwise.

3. Using a square (37), set the blade to exactly 90°. (Fig. 6-2)

4. If the blade stops bevelling before it gets to 90°, loosen the 90°

stop screw (38) (located in the left of the table insert) (Fig. 6-1)

with the 5 mm hex key (supplied), and then adjust it to 90°.

5. With the blade set at 90°, slowly turn the 90°-stop set screw until

you feel resistance. Bevel the blade away from 90° a little, and

then back to the stop.

6. Re-measure the angle, and repeat the stop adjustment as

necessary until the blade stops at 90°.

7. Set the 45° stop in the same way. The set screw for the 45° stop

(39) is located in the right of table insert.

INSTALLING BATTERY FOR LASER GUIDE (FIG. 7-1 & 7-2)

WARNING: The laser must align with the saw blade.

1. Raise the saw blade (13) to the heightest position.

2. Turning the saw blade to 0° position and lock blade bevel lock

knob (8).

3. Loose the cross-screw (40) with the screwdriver (not supplied).

4. Remove the laser cover (41).

5. Place the batteries (42).

NOTE: Pay attention to correct polarity.

6. Refix the laser cover (41).

7. Tighten the cross-screw (40).

WARNING: Do not operate when the saw is on working.

ADJUSTING LASER GUIDE (FIG. 7-1)

WARNING: The laser must align with the saw blade.

1. Raise the saw blade (13) to the heightest position.

2. Turning the saw blade to 0° position and lock blade bevel lock

knob (8).

3. Loosen the two cross-screws (43).

4. Align the laser (44) to the saw blade.

5. Tighten the two cross-screws (43).

LASER GUIDE

1. A laser beam is not a toy, and it should not be used by children.

Misuse of the laser line can lead to irreparable eye damage.

2. It is strongly advised that you use laser protective eyewear for

the specific wavelength of emitted light when working on or near

reflective surface.

3. Do not perform any adjustments that are intended to increase

the power of the laser.

4. When using the laser line, do not point the laser beam at people

and/or reflecting surface. Even a low-intensity laser beam can

cause eye damage. Do not look directly into the laser beam.

5. If the laser line will not be used for more than three months.

Remove the batteries in order to avoid damage from possible

leakage.

6. The laser line does not include any user-serviceable components.

Do not open the housing in an attempt to repair it.

7. Repairs should only be carried out at a service centre or by an

authorized service technician.

TO ASSEMBLE THE BLADE GUARD (FIG. 8-1 & 8-2)

WARNING: The saw blade guard must be in position at all times

to prevent contact with the blade. It should lift up and onto

the workpiece when the workpiece is passed through the saw.

1. Attach the blade guard (1) over the riving knife (3) so that the

hole in the guard and the hole in the riving knife are aligned.

2. Insert the screw M6 x45 (31) and fit the flat washer 6 (32) and

hex nut M6 (30).

3. Tighten the hex nut (30) sufficiently so that the guard rests on

the table top but will lift when the workpiece is pushed into the

table.

4. Blade guard (1) in place as shown in Fig. 8-2.

WARNING: The blade guard should return to its rest position after

the workpiece has been cut.

CHANGING THE BLADE DEPTH (FIG. 9)

The saw blade depth should be set so that the outer points of the

saw blade are higher than the workpiece by approximately 1/8” (3.2

mm) to 1/4” (6.4 mm), but the lowest points (gullets) (45) are below

the top surface.

1. Unplug the saw.

2. Turn the blade bevel lock knob (8) clockwise to tighten it

securely.

3. Raise the blade (13) by turning the height adjusting handle

clockwise, or lower it by turning the handle counterclockwise.

CHANGING THE BLADE ANGLE (FIG. 10)

1. Unplug the saw.

2. Loosen the blade bevel lock knob (8) by turning it counterclockwise.

3. To adjust the bevel angle, turning the height/bevel adjusting

handwheel (10) counterclockwise increases the angle of the blade,

bringing it closer to 45°; Turning it clockwise decreases the angle,

bringing the blade closer to 90°.

4. To lock by turning the blade bevel lock knob (8) clockwise.

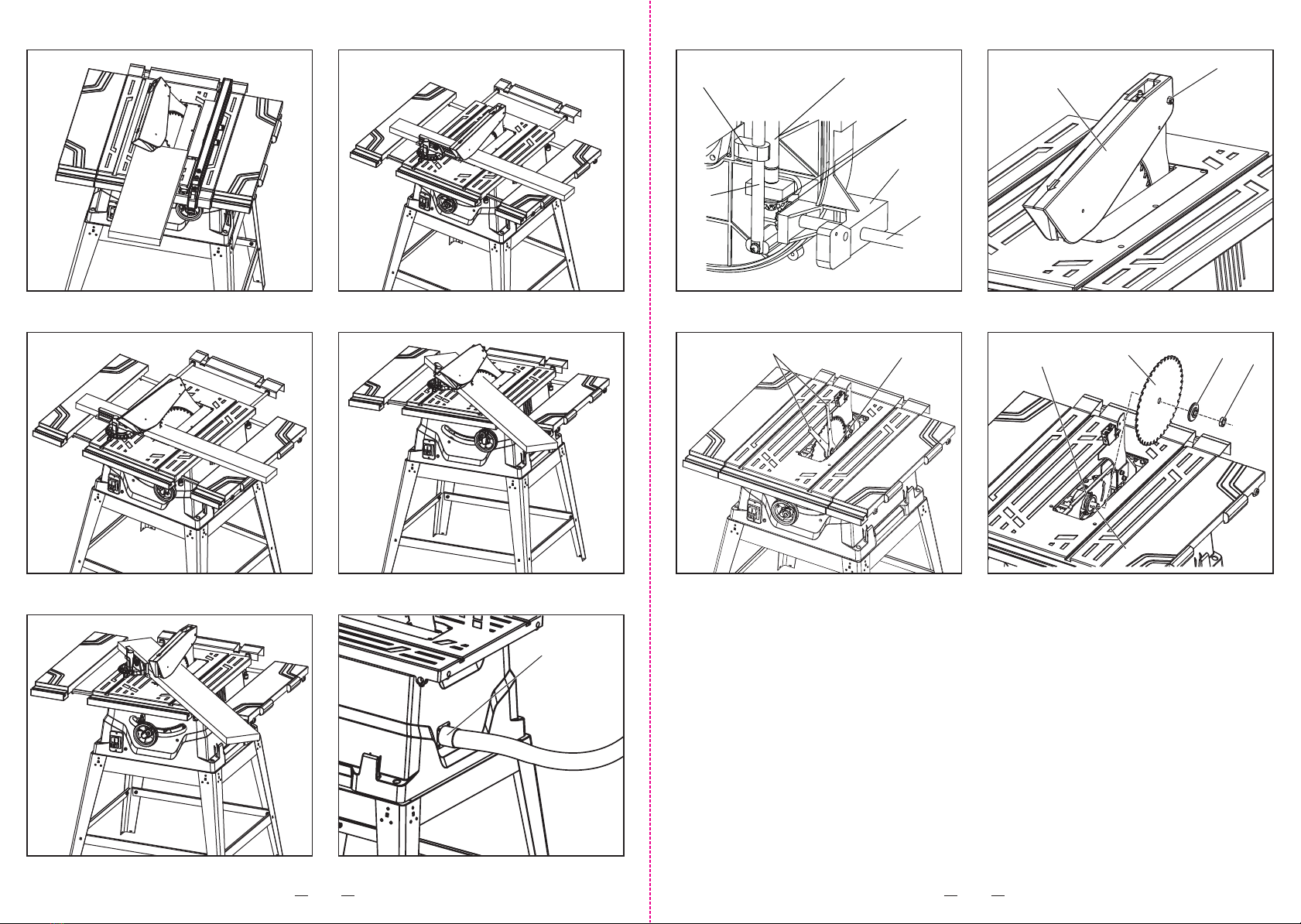

ASSEMBLY THE SIDE EXTENSION TABLE (FIG. 11-1 & 11-2)

1. Sliding the tubes (46) into the two holes at the side of the main

table.

2. Fix the screws M4 x 10 (47) into the holes at the end of both

extension tubes to prevent you from pulling the side table too far

out.

3. You can lock at the desired position with the two locking knobs

(48) at the bottom of the main table.

ASSEMBLY THE REAR EXTENSION TABLE (FIG. 12-1 & 12-2)

1. Sliding the tubes (46) into the two holes at the back of the main

table.

2. Fix the screw M4 x 10 (47) into the hole at the end of extension

tube located near the sliding table to prevent you from pulling the

side table too far out.

3. You can lock at the desired position with the two locking knobs

(48) at the bottom of the main table.

TO ASSEMBLY THE RIP FENCE (FIG. 13)

Lift the rip fence handle (49) until the rear holding clamp (50) is fully

extended.

1. Place the rip fence (4) on the saw table, lowering the rear of the

fence onto the table first.

2. Push down the rip fence handle (49) in order to lock the rip fence

in position.

ADJUSTING THE RIP FENCE INDICATOR (FIG. 14)

1. The rip fence indicator (51) points to the measurement scale (52).

The scale shows the distance from the side of the fence closest

to blade.

2. Measure the actual distance with a ruler. If there is a difference

between the measurement and the indicator, adjust the indicator.

Loosen the screw, and slide the indicator to the correct

measurement on the scale. Tighten the screw, and re-measure

with the ruler.

TO ASSEMBLY THE AUXILIARY RIP FENCE (Fig. 15-1 & 15-2)

When cutting narrow workpieces and for bevel cuts, the auxiliary

rip fence (15) (aluminum) must be mounted to the rip fence (4).

The auxiliary rip fence (15) can be mounted left or right side of the

rip fence (4).

1. Insert the profile rail into the groove on the short side of

the auxiliary rip fence.

2. Position the profile rail in front of the rip fence in such a manner

that the holes of both parts are in alignment.

3. Insert the fastening knobs (53) through the lateral holes in the rip

fence and tighten them.

When sawing high, narrow work pieces, the auxiliary rip fence

(aluminum) must be mounted directly to rip fence.

1. Fasten the auxiliary rip fence with the 2 square nuts (54) (not

supplied) and the fastening knobs directly to the rip fence.

INSTALLING THE MITER GAUGE (Fig. 16-1 & 16-2)

1. Attach the rip fence for miter gauge (55) to the miter gauge by

tighten two locking knobs (56). (Fig. 16-1)

2. Insert the guide rail of the miter gauge into one of the guide

grooves (57) of the saw table intended for this purpose.

ADJUSTING THE MITER GAUGE (Fig. 17-1 & 17-2)

1. Loosen the locking handle (58) in order to allow the miter body

(59) to rotate freely.

Position the miter body at 90° so that the positive detent secures

it in position. Tighten the locking handle in order to hold the miter

body securely in position.

2. If the pointer (60) requires adjustment, loosen the cross-screw

(61) that is located under the pointer using a screwdriver. Adjust

the pointer to 90° on the scale, and then tighten the adjusting

screw firmly.

3. In order to change the angle of the miter gauge, loosen the

locking handle (58) and the rotate the miter body (59) to

the desired angle, as indicated on the scale. Tighten the locking

handle (58) in order to hold the miter body (59) securely

in position.

OPERATION

For safety reasons, verify that the operator has read the section

entitled general safety guidelines for the table saw before operating

this saw. Verify the following before every time the table saw

is used:

• The blade is tight.

• The blade bevel lock knob is locked.

• If ripping, the rip fence locking knob is tight, and the fence

is parallel to the miter gauge groove and the blade.

• If crosscutting, the miter gauge knob is tight.

• The blade guard and splitter are in place, and are working properly.

• Safety glasses are worn.

• Failure to adhere to these safety rules will greatly increase the

chances of injury.

Before using the table saw, polish the tabletop with an automotive

polishing wax in order to keep it clean, and to make it easier to slide

the workpiece.

There are two basic types of table saw cuts: ripping and crosscutting.

Ripping refers to cutting along the length of the grain and the work

piece. Crosscutting refers to either cutting across the width or across

the grain of the work piece. This distinction may be hard to make

with man made materials. Therefore, cutting a piece of material

to a different width is ripping, and cutting across the short dimension

is crosscutting.

Neither operation can be performed safely freehand: ripping requires

the use of the rip fence, and crosscutting requires the use of the

miter gauge. Never use the rip fence and the miter gauge at the

same time during the cutting operation.

ON/OFF SWITCH (Fig. 18)

Switching On

To start the operation, press the green I-push button (62).

Switching Off

Press the red O-push button (63) to stop the saw.

OVERLOAD PROTECTION (Fig. 19)

This saw is equipped with a reset overload relay button. It is situated

at the immediate right of the ON/OFF switch.

The reset button will restart the motor after it shuts off due

to overloading or low voltage.

If the motor stops during operation, press the red O-push button (63)

to make sure the switch is OFF. Wait approximately five minutes

for the motor to cool down and push the reset button. Now you can

switch to the ON position again.

WARNING: In order to avoid injury and prevent accidental start-up

when the reset button is pushed, the switch should be in the off

position, and the power cord should be unplugged from the outlet

while the saw is cooling down. Overheating may be caused by an

under-sized extension cord, an extension cord that is too long,

misaligned parts, or a dull blade. inspect the saw for proper set-up

before using it again.

USING SIDE EXTENSION TABLE (Fig. 11-1 & 11-2)

1. Unlock the side extension table locking knob (48) underneath

the main table.

2. Slide the extension tubes (46) in or out until the scale on the tube

is positioned at the desired distance. Lock the extension table

locking knob (48).

3. To adjust the position of the rip fence, loosen the locking handle

(49), and place the auxiliary rip fence (15) in position by using

the calibration point in red.

4. Tighten the locking handle (49).

USING REAR EXTENSION TABLE (Fig. 12-1 & 12-2)

1. Unlock the rear extension table locking knob (48) underneath

the main table.

2. Slide the extension tubes (46) in or out until the tube is positioned

at the desired distance. Lock the extension table locking knob

(48).

RIPPING (Fig. 20)

1. Remove the miter gauge, and secure the rip fence to the table.

2. Raise the blade until it is approximately 1/8” (3.2 mm) above the

top of the work piece.

3. Place the work piece flat on the table and against the fence so

that the larger portion of the work piece is between the blade and

the fence. Keep the work piece approximately 1” (2.5 cm) away