S.I.S.E. MV3-IM Series User manual

www.sise-plastics.com

SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En

MV3-IM and MV3-TS Series USER Guide

Hot runner temperature control

Software MV3-IM and MV3 Series Multizone Controllers

Written by : K. PERRIN

Date : 08/04/19

Approved by : NCN

Date : 08/01/20

Change history Date Change description

A 08/04/19 Merge MV3-IM and MV3-TS, 6.0 Version

B 08/01/20 Version 7.3

Translated from the original manual

Page 3 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

1) FIRST START-UP.................................................................................................................. 5

2) GENERAL PRESENTATION OF THE INTERFACE .......................................................... 5

2.1) C .......................................................................................................... 5

2.1.1) Contextual help ............................................................................................................... 6

2.1.2) Locking/Unlocking the user interface ........................................................................ 6

2.1.3) Screen shots ................................................................................................................. 7

2.1.4) Navigation and screens .................................................................................................. 7

2.2) S ........................................................................................................... 9

2.3) G ......................................................................... 10

2.3.1) Information on heating zones........................................................................................ 10

2.3.1.1) Control screen.................................................................................................. 10

2.3.1.2) Alarm screen.................................................................................................... 11

2.3.2) Changing the number of zones displayed..................................................................... 13

2.3.2.1) Zoom in or out by swiping ................................................................................ 13

2.3.2.2) Zoom in or out using the navigation icon ......................................................... 14

2.3.3) Selection .......................................................................................................................14

3) USING THE SYSTEM ......................................................................................................... 15

3.1) S ......................................................................................................... 15

3.1.1) Software configuration .................................................................................................. 15

3.1.1.1) General configuration....................................................................................... 15

3.1.1.2) Regional parameters........................................................................................ 16

3.1.1.3) Changing the interface lock passwords ........................................................... 17

3.1.1.4) Network settings............................................................................................... 18

3.1.2) Temperature control configuration................................................................................ 18

3.1.2.1) Temperature control configuration settings...................................................... 18

3.1.2.2) Ramp Softstart Settings ................................................................................... 19

3.1.2.3) Heating zone configuration .............................................................................. 21

3.1.2.4) Zone Groups .................................................................................................... 26

3.1.2.5) Zone configuration table................................................................................... 28

3.1.3) Configuration files ......................................................................................................... 29

3.1.3.1) Creating a configuration file ............................................................................. 30

3.1.3.2) Displaying a configuration file .......................................................................... 31

3.1.3.3) Loading a configuration file.............................................................................. 32

3.1.3.4) Updating a configuration file............................................................................. 32

3.1.3.5) Deleting a configuration file.............................................................................. 32

3.1.3.6) Duplicating a configuration file ......................................................................... 32

3.1.3.7) Exporting and importing configuration files using a USB flash drive................ 33

3.2) N ........................................................................................................................... 35

3.2.1) Selecting the operating mode ....................................................................................... 35

3.2.1.1) Description of operating modes ....................................................................... 35

3.2.1.2) Setting the operating mode.............................................................................. 36

3.2.1.3) Changing the system mode ............................................................................. 36

3.2.2) Heating zone management........................................................................................... 37

3.2.2.1) "Quick change" action bar ............................................................................... 37

3.2.2.2) Automatic and manual setpoint........................................................................ 38

3.2.3) Alarms........................................................................................................................... 38

3.2.3.1) Viewing alarms................................................................................................. 38

3.2.3.2) Alarm log.......................................................................................................... 39

CONTENTS

Page 4 / 60

www.sise-plastics.com

3.2.3.3) Alarm Parameters ............................................................................................ 40

3.2.4) Electrical analysis of the mold....................................................................................... 41

3.2.4.1) Mold verification (MoldScan) ........................................................................ 41

3.2.4.2) Readings .......................................................................................................... 42

3.2.4.3) Mold monitoring................................................................................................ 42

3.2.4.4) Consumption .................................................................................................... 46

3.3) A ........................................................................................................... 46

3.3.1) Remote log-in................................................................................................................ 46

3.3.2) Communication ............................................................................................................. 47

3.3.3) System information ....................................................................................................... 47

3.3.3.1) Restoring factory settings .............................................................................. 48

3.3.3.2) Loading a company logo ................................................................................. 48

3.3.4) Data acquisition ............................................................................................................ 49

3.3.4.1) Data recording.................................................................................................. 49

3.3.4.2) Curves ............................................................................................................. 51

3.3.5) Documentation files ...................................................................................................... 52

3.3.6) Programmable Clock .................................................................................................... 53

3.3.6.1) Weekly Planning ........................................................................................... 53

3.3.6.2) Duration Programming ............................................................................. 54

4) MAINTENANCE INSTRUCTIONS..................................................................................... 55

4.1) T............................................................................................................... 55

5) CONTACT US...................................................................................................................... 58

Page 5 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

1) FIRST START-UP

Connect the power cord to the appropriate power supply (see nameplate and operating instructions).

Check all incoming and outgoing connections.

Turn on the system using the interruptor located on the front.

After a few seconds, the display screen lights up.

System type/

Serial number/

Software version

2) GENERAL PRESENTATION OF THE INTERFACE

2.1) C

The user interface always displays these 3 elements:

Status bar at the bottom of the screen

Action bar on the right side

4 navigation tabs at the top of the screen

Navigation

tabs

Contextual

help

Interface

locking

Status bar

Screen

capture

Information on

current screen

Name of the

screen

Operating mode

indicator

Action

bar

Loaded

configuration

file name

Date and time

Page 6 / 60

www.sise-plastics.com

The status bar provides general information on the system status such as date and time, current

configuration file, current screen name (as well as other information relevant to the screen such as

the number of zones displayed out of the total number of zones, the number of zones selected and

the number of zones in alarm), current operating mode (Stop/Gradual stop/Standby/Production - see

§3.2.1). On the left, there are also three icons for actions concerning the graphical user interface.

The status bar blinks red if alarms are triggered.

The contents of the Action bar depend on the screen currently in view and display icons which act

directly on system settings.

2.1.1) Contextual help

The question mark icon activates or deactivates the contextual help function displaying a description

over the icons. This function is useful during learning how to use the user interface or when you have a

doubt about the meaning of an icon.

2.1.2) Locking/Unlocking the user interface

There are 3 privilege levels which allow access to all or some of the interface functions. The current

privilege level is displayed at the bottom of the page:

Current privilege

level

Page 7 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

Functions available for the different privilege levels are listed below:

Privilege level Accessible functions

0 The interface is "read-only", no changes can be made to the system.

1

Possible modifications are:

• Change a setpoint

• Turn zones On/Off

• Auto/Manual mode

• Change the operation mode

• Load a file

2 The interface is fully accessible, all modifications are possible.

By default, on start-up, the user interface is not locked (privilege level 2), all functions are accessible.

By pressing the open or closed padlock icon at the bottom of the screen, a numeric keypad

appears allowing changes to the privilege level by entering the appropriate password:

• to change to privilege level 1, enter the default password for this level, "654321",

to confirm press ;

• to change to privilege level 2, enter the default password for this level, "123456",

to confirm press ;

• to change to privilege level 0, enter the password of the current level, to confirm press .

To change the passwords for privilege levels, refer to §3.1.1.3.

To set the user level on start-up, refer to §3.1.1.1.

2.1.3) Screen shots

The camera icon is displayed when a USB flash drive or hard disk is connected. This icon enables

you to capture screens and save them at the root of your USB device.

Note: Please wait a few seconds before withdrawing the USB device to make sure that your screen

capture is completely saved on the system.

2.1.4) Navigation and screens

The four navigation tabs at the top of the screen represent the four different views provided in the user

interface: System view, Control view, Alarm view and Configuration view.

The current view depends on which tab is selected.

Each tab gives access to a set of screens. For example, to change or view the settings of one or more

zones, press "Control view" . The different screens of this view are represented by thumbnails.

Page 8 / 60

www.sise-plastics.com

Select the

appropriate

thumbnail to

access the

screen

Press the tab to return to

this display

Press the «Zone configuration table» thumbnail to go to that screen. You can now check the status of

the control zones by clicking on the "Control view" tab and by selecting the "Control" thumbnail.

Page 9 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

2.2) S

The screens are assigned to the different views according to their function:

• The SYSTEM view pertains to the whole system (i. e. mold files).

• The CONTROL view pertains to the temperature control.

• The ALARM view pertains to alarm management.

• The CONFIGURATION view pertains to the software configuration options.

The table below gives a summary of the screens available under the different tabs.

Tab Screen

System

• Configuration files

• Operating Mode

• Time Programming / Scheduling

• Documentation

Control

• Control

• Zone configuration table

• Temperature control settings

• Power consumption

• Mold monitoring

• MoldScan

• Group management

• Ramp settings

• Data acquisition

Alarms

• Table of active alarms

• List of active alarms

• Alarm log

• Alarm Parameters

Configuration

• General configuration

• Regional parameters

• Privileges

• Network settings

• System info

• External parameters

Page 10 / 60

www.sise-plastics.com

2.3) G

The "Control" and "Table of active alarms" screens both contain information on the heating zones. On

each of these screens the zones are represented in a grid: zoom in or out to re-size this grid.

"Control" screen "Table of active alarms" screen

2.3.1) Information on heating zones

The information displayed for each zone also depends on the selected zoom level and on the screen

size.

The color indicates the status of the zone:

• Red: zone with alarm.

• Green: zone without alarm.

• Grey: zone OFF.

• Blue: zone with low temperature alarm.

• Purple: zone using the temperature probe of another zone.

The name of the reference zone is displayed in place of the setpoint temperature.

• White: zone ON, system in STOP mode.

• Beige: zone under surveillance

2.3.1.1) Control screen

Max. information displayed

Zone with alarm Zone switched off

Zone name + Group identification icon

Group

Temperature

Status

% of power or current Configuration

Setpoint or slave zone

Page 11 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

Min. information displayed

Zone without alarm Zone with low temperature alarm

Zone name + Group identification icon

Temperature

Status

The meaning of the various status icons is described below:

Icon Description

Temperature of the zone is below setpoint: Low temperature alarm.

Temperature of the zone is above setpoint: High temperature alarm.

The zone has an alarm triggered which is not High or Low temperature.

A ramp has been applied to the zone so that its setpoint can be gradually reached.

The zone is in Boost mode (§3.1.2.1- §3.1.2.3).

The zone is backed up: the power applied to the zone is identical to the power

applied to the slave zone (§3.1.2.3).

The zone is in manual mode. The power applied is set by the ‘Manual Setpoint».

There is no temperature control on the zone.

The zone is being monitored

2.3.1.2) Alarm screen

The information displayed for each zone also depends on the selected zoom level and on the screen

size.

The color indicates the status of the zone just like in the control screen.

Max. information displayed

Zone in high temperature alarm or other alarms Zone without alarm

Zone name + Group identification icon

Group

Temperature

Temperature alarm

% of power or current

Power alarm

Page 12 / 60

www.sise-plastics.com

Min. information displayed

Zone with high temperature alarm or other alarms Zone with low temperature alarm

Zone name + Group identification icon

Temperature alarm

Power alarm

The meaning of the various temperature alarm icons is described below:

Icon Fault

Temperature of the zone is below setpoint: Low temperature alarm.

Temperature of the zone is above setpoint: High temperature alarm.

Cut Thermocouple.

Reversed Thermocouple.

The zone is in manual mode after the thermocouple has been cut.

This function must be previously activated (§3.1.2.1).

Zone temperature is above the abnormally high temperature threshold (§3.1.2.1).

The meaning of the power alarm icons is described below:

Icon Fault

Load Fault.

Power monitoring detected a different power than the reference measurement.

Triac fault on the zone.

Current measurement is different from the reference measurement.

A power supply phase is absent on the power cards.

Overvoltage

Page 13 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

2.3.2) Changing the number of zones displayed

It is possible to zoom in or out so as to display more or fewer zones. This allows an overall view of

the system showing fewer details for each zone, or alternatively to view more information of a smaller

number of zones.

The various zoom levels depend on the screen set up on the system:

• 7" landscape-oriented screen: 48, 24, 16, 12 or 8 zones can be displayed at once.

• 10" and 15" portrait screens: 96, 72, 48, 24 or 16 zones can be displayed at once.

The zoom level can be changed in either of two ways: either by swiping diagonally upwards to zoom in

(displaying fewer zones) and diagonally downwards to zoom out (displaying more zones), or by using

the navigation icon in the Action bar.

2.3.2.1) Zoom in or out by swiping

Zoom in Zoom out

The number of zones currently displayed is shown in the status bar. If the system is capable of managing

more zones than the number currently displayed, you can navigate around the zones displayed by

swiping upwards or downwards. There is a position indicator on the right-hand side of the window giving

further information on the scrolling of the zones.

Number of zones which can be displayed

and number of zones currently displayed

Scroll

Bar

Towards

zone 1

Towards

the last

zone

Page 14 / 60

www.sise-plastics.com

2.3.2.2) Zoom in or out using the navigation icon

Pressing the navigation icon in the Action bar brings up a double icon bar with the following

actions:

Icon Action

Scroll up, equivalent to moving towards the first zone.

Scroll down, equivalent to moving towards the last zone.

Zoom in, display fewer zones but with more detail.

Zoom out, display more zones but with less detail.

2.3.3) Selection

It is possible to carry out certain operations on only specifically selected zones. These zones can be

selected by pressing a zone, which is then highlighted in orange:

Selected zone

Pressing an already-selected zone deselects it.

It is also possible to select or deselect several zones at the same time by using the selection menu in

the Action bar . Once this menu has been activated, a double Action bar offers the following actions:

Icon Action

Exit the selection menu

Select zones by group

Select all zones

Deselect all zones

You can also select a set of zones by pressing the first zone desired (e.g. zone 3) and then holding down

the last zone desired (e.g. zone 7). All zones between these two will then be selected (zone 3 to zone 7).

Page 15 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

3) USING THE SYSTEM

In order to use the system correctly, it is necessary to configure it properly before you use it for the first

time. This greatly facilitates daily use.

The software also has advanced features including remote operation and customizable company

information.

3.1) S

3.1.1) Software configuration

Software configuration is done during its first use, or occasionally if you want to change an overall

software setting.

3.1.1.1) General configuration

The overall settings of the software can be configured in the "General configuration" screen, accessible

in the "Configuration" view .

Electric current display :

It is possible to choose the display of the applied power (% of nominal power or load current in Amperes).

This mode chosen will be used in displaying the zones on the "Control" and "Alarms" pages.

Temperature units :

The preferred temperature units (°C or °F) will be used throughout the interface.

Page 16 / 60

www.sise-plastics.com

Heating neutralization input action :

This option is used to select the action of the HEATING NEUTRALIZATION input (see §6.4 of the

Operating instructions). This input makes the system switch to the ‘Stop’ or ‘Gradual stop’ states. To

restart heating, changing the input is necessary, but not enough. The Operating mode selector of the

screen must be used (except for the last option: see the list of options below).

Possible actions are:

• No action: the input is ignored.

• Stop if the input is open: the system enters 'Stop' mode if the input is set to 0.

• Stop if the input is closed: the system enters 'Stop' mode if the input is set to 1.

• Gradual stop if the input is open: the system enters 'Gradual stop' mode if the input is

set to 0.

• Gradual stop if the input is closed: the system enters 'Gradual stop' mode if the input is

set to 1.

• Stop if the input is open, ... Production if the input is closed: the system enters ‘Stop’ mode if

the input is open, and ‘Production’ mode if the input is closed.

Standby input action :

This option is used to select the action of the STANDBY input (see §6.4 of the Operating instructions).

Possible options are:

• No action: the input is ignored.

• Standby if the input is open: the system enters 'Standby' mode if the input is set to 0 AND current

mode is 'Production'. Switching to' Production' mode is no longer possible via the display.

• Standby if the input is closed: the system enters 'Standby' mode if the input is set to 1 AND

current mode is 'Production'. Switching to' Production' mode is no longer possible via the display.

For a description of the operating modes, see §3.2.1.

Priviledge on power-up :

This option is used to select the privilege level applied on power-up. Possible options are:

• Priviledge 0: The system will always start at priviledge level 0.

• Priviledge 1: The system will always start at priviledge level 1.

• Priviledge 2: The system will always start at priviledge level 2.

• Current level: The system will start at the priviledge level at which it was turned off.

For a description of priviledge levels, see §2.1.2.

3.1.1.2) Regional parameters

Regional parameters are date, time and language settings used by the interface. They can be configured

in the "Regional parameters" screen, accessible in the "Configuration" view .

Page 17 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

Choose

language

Set date and

time Time zone

To change the date, press one of the fields (day, month, year), then use the up and down arrows to

increase/decrease the value in this field.

To change the language of the interface, click on the corresponding flag.

The time zone parameter must be specified when a time server is used (§3.1.1.4) and for the automatic

calculation of summer/winter time.

The modifications are confirmed when the icon is pressed. In case of language change, the interface is

reloaded and the "System" view is displayed.

3.1.1.3) Changing the interface lock passwords

The password for privilege levels 1 and 2 can be changed in the "Priviledge" screen. The user will be

asked for both the current and new passwords.

Page 18 / 60

www.sise-plastics.com

3.1.1.4) Network settings

Choose to assign an IP address automatically or manually, and configure network settings such as a

Network mask or Gateway. Connect an ethernet cable between the unit and a PC or Injection Molding

Machine to modify the network parameters.

The icon indicates that the system is connected and the network is working. The icon

indicates that the system is not connected.

When using a remote screen or VNC client display, network configuration will not be possible.

3.1.2) Temperature control configuration

The temperature control configuration is used to adapt software operation to the mold in use.

It is to be carried out during the first use of a mold.

3.1.2.1) Temperature control configuration settings

The "Temperature control settings" screen, accessible in the "Control" view , allows you to

configure the parameters associated with temperature control.

Page 19 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

Minimum automatic mode setpoint and maximum automatic mode setpoint :

Maximum and minimum setpoints can be specified for the automatic mode.

Abnormally high temperature threshold :

This value determines the temperature above which an Abnormally high temperature alarm is triggered,

even if the zone involved is stopped.

Changeover to manual mode if a thermocouple is cut :

If a thermocouple is cut, the zone concerned switches to manual mode, with the last power percentage

applied. This allows production to continue.

Boost duration :

The duration of the Boost function can be set in this field. For more information on this function, see

§3.1.2.3 - Configuring Boost value and §3.1.2.5.

The Boost function can unblock an injection point where the material is too cold.

Boost Duration without alarm :

With this field, you can specify the duration during which no temperature alarm will be triggered after

boosting.

Start-up mode on power-up :

This field allows you to specify the default operating mode of the system.

For a description of the operating modes, see §3.2.1.

3.1.2.2) Ramp Softstart Settings

The "Ramp settings" screen, accessible in the "Control" view , allows you to set the heating ramp

parameters.

Depending on the type of ramp selected, different parameters appear, along with a curve to visualize

them.

Page 20 / 60

www.sise-plastics.com

Start-up ramps:

On start-up, the zones in automatic mode are heated gradually until they reach their operating setpoint.

There are four possible types of start-up ramps:

Duration ramp

The system heats at the maximum gradient of A,

then maintains the temperature at B for a period

of C minutes.

During cooling, gradient E will be applied

down to temperature I, considered cold.

Gradient ramp

The system heats at the maximum gradient of A.

During cooling, gradient E will be applied

down to temperature I, considered cold.

Synchronized ramp

y

The system automatically selects the zones which

are working properly (no failed thermocouples or

heating elements), and then starts heating these

zones. An algorithm allows the fastest zones to

follow the temperature evolution of the slowest

zones, within the maximum gradient A.

During cooling, slope E will be

applied down to temperature I, considered cold,

and the fastest zones will follow the slowest zones.

Staggered ramp

gg

This ramp uses the grouping of zones in

manifold or nozzle groups (§3.1.2.4). Initially all

the zones in "manifold" type groups are heated

in a synchronized ramp, while the zones in

"nozzle" type groups are kept at temperature B

for a period of time C. When all the zones in the

"manifold" groups have reached their particular

setpoints, the system stabilizes their heating by

means of a waiting time D, and then executes

a synchronized ramp on the zones in the

"nozzle" groups. The staggered ramp is terminated

when all zones have reached their operating

setpoints.

During cooling, the nozzles will be

first cooled and then stabilized at temperature

F for a period of time G, then the blocks will be

cooled at the same temperature, then stabilized

for a period H. Finally, all zones will be cooled

down synchronously to temperature I, considered

cold.

Page 21 / 60SISE_M_REGUL_SerieM_MV3-IM_MV3-TS_V7.3_20200108_B_En www.sise-plastics.com

A and E ramp gradients:

A and E ramp gradients determine the heating / cooling gradient and thus the instantaneous power

consumption. Settings will therefore be done according to criteria of technical necessity and the need to

limit the peak current during heating.

Optimized power consumption AND non-optimized heating time.

Moderately optimized power consumption AND optimized heating time.

Unlimited power consumption AND heating time reduced to a minimum.

Uncontrolled cooling time.

Optimized cooling time.

Maximum cooling time.

Power restriction :

In all four start-up modes power is limited to 15% at the start of the ramp for 1 minute or until the zone

reaches 100°C.

3.1.2.3) Heating zone configuration

Heating zones can be configured from the "Control" page or from the "Zone configuration table" (§3.1.2.5).

The "Control" screen is accessible in the "Control" view .

To configure a heating zone, press it twice ("double-click" on it) or press the Zone configuration icon

.

To configure more than one heating zone simultaneously, select a number of zones (§2.3.3) and press

one of them twice ("double-click"). This zone then becomes the "reference zone".

This brings up the Zone configuration screen:

Selected zones

This manual suits for next models

1

Table of contents

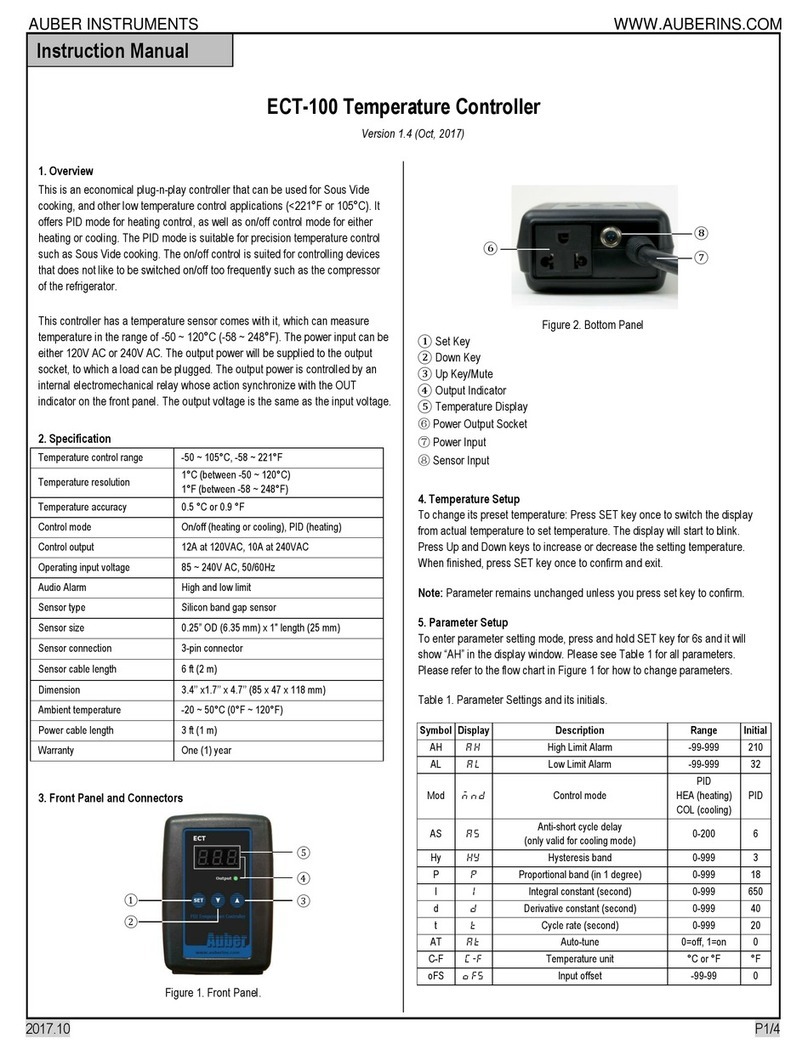

Popular Temperature Controllers manuals by other brands

Auber Instruments

Auber Instruments ECT-100 instruction manual

Nibe

Nibe PCM 40 Installer manual

Dwyer Instruments

Dwyer Instruments 16A2 Series instructions

NOUS

NOUS E6 instruction manual

Temperature Guard

Temperature Guard VM500-2 Operating Manual and Installation Instructions

dixell

dixell XH360L operating instructions

Omega

Omega CN76000 manual

Danfoss

Danfoss ECL Comfort 110 operating guide

Hydrolevel Company

Hydrolevel Company Fuel Smart HydroStat 3200 Installation instructions and operating manual

Ekinex

Ekinex EK-EQ2-TP- Series Applications manual

Auber

Auber WS-1500EBPM operation instruction

SYStronics

SYStronics STH-PR5N-F user manual