Saalasti Crush HF Series 2 (47)

VM-20190708 Operation and maintenance manual 08.07.2019

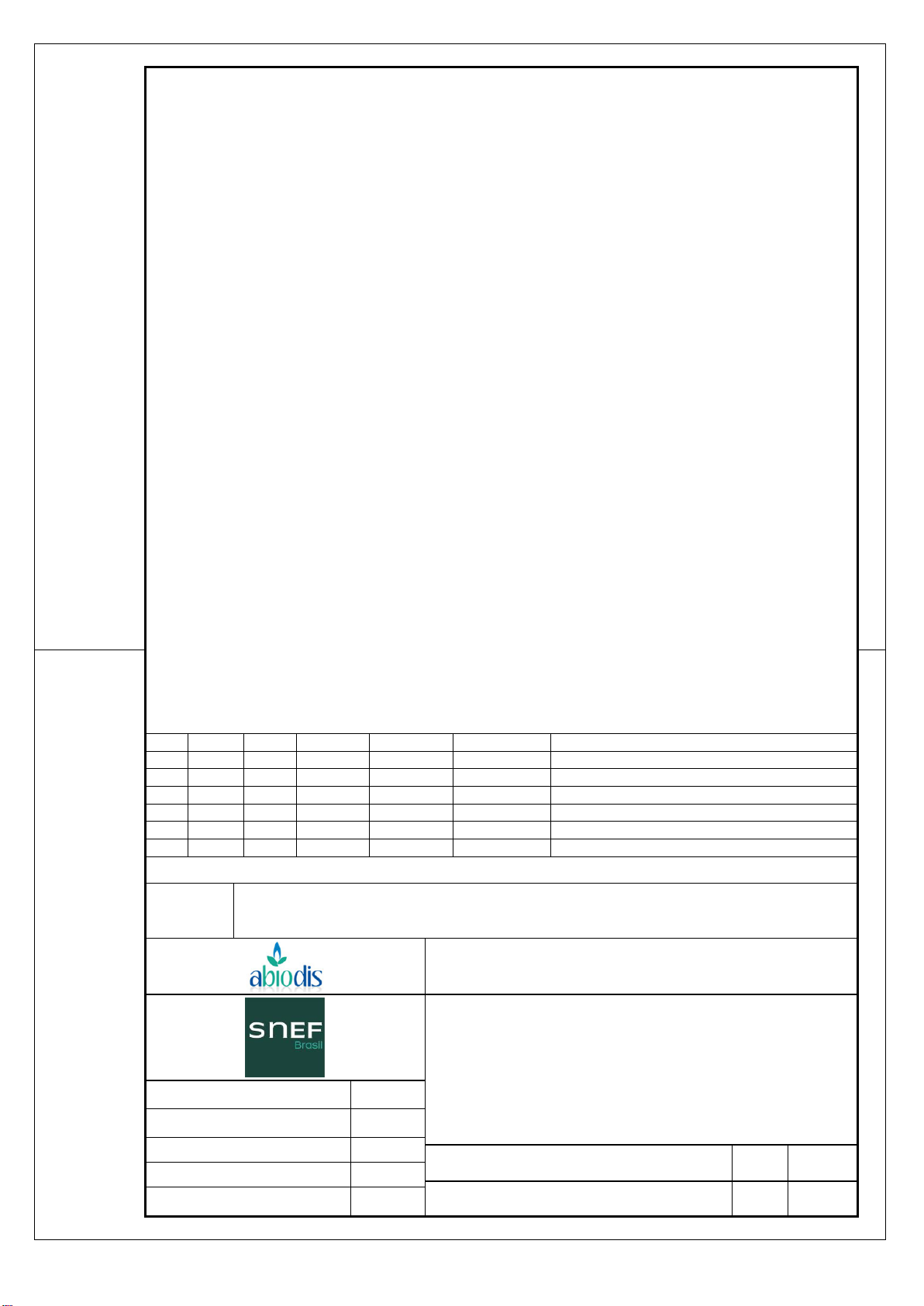

Table of Contents

1INTRODUCTION.......................................................................................................................3

2OPERATION PRINCIPLE.........................................................................................................4

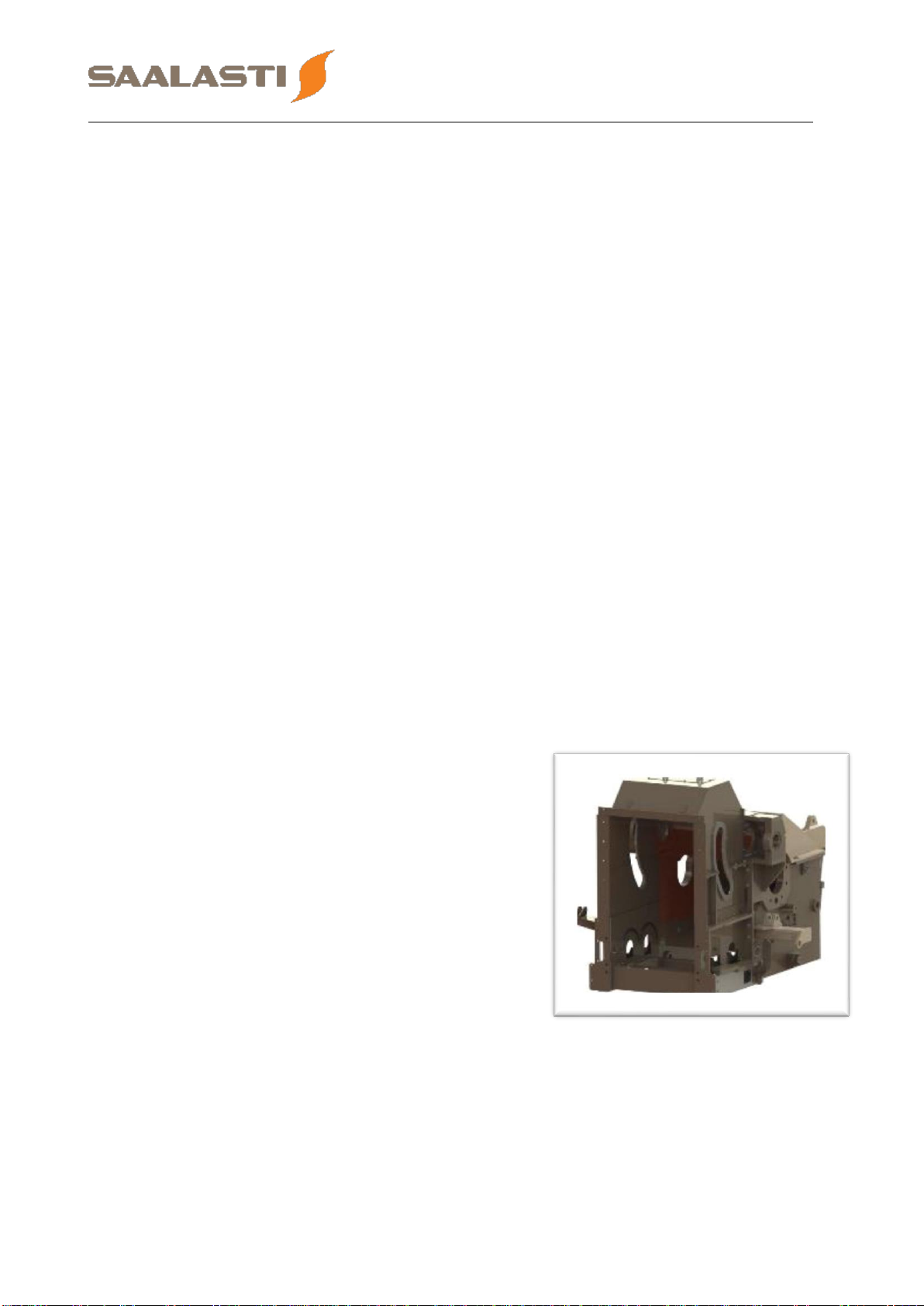

2.1 Frame........................................................................................................................................4

2.2 Lower rolls...............................................................................................................................5

2.3 Upper roll .................................................................................................................................5

2.4 Rotor.........................................................................................................................................6

2.5 Anvil Plate................................................................................................................................7

2.6 Grate.........................................................................................................................................7

3OPERATING INSTRUCTION...................................................................................................9

3.1 Before starting the Saalasti Crush........................................................................................9

3.2 Starting the Saalasti Crush ....................................................................................................9

3.3 Stopping the Saalasti Crush..................................................................................................9

3.4 Fuel selection ..........................................................................................................................9

3.5 Disturbance situations ...........................................................................................................9

4SAFETY INSTRUCTIONS......................................................................................................10

4.1 Safety in operation................................................................................................................10

4.2 Safety in maintenance ..........................................................................................................11

5MAINTENANCE......................................................................................................................15

5.1 Rotor cutting tools change ..................................................................................................15

5.2 Anvil plate cutter inserts ......................................................................................................19

5.3 Anvil plate wear plate ...........................................................................................................20

5.4 Anvil plate pins......................................................................................................................21

5.5 Grate pins...............................................................................................................................22

5.6 Changing a shear pin............................................................................................................23

5.7 Grate.......................................................................................................................................25

5.8 Frame wear plates.................................................................................................................27

5.9 V-belts ....................................................................................................................................27

5.10 Gear boxes.............................................................................................................................31

5.11 Lubrication.............................................................................................................................32

6HYDRAULICS.........................................................................................................................35

6.1 Hydraulic pump.....................................................................................................................36

6.2 Air/Oil cooler..........................................................................................................................36

6.3 Immersion heater ..................................................................................................................36

6.4 Tank equipments...................................................................................................................37

6.5 Oil purity.................................................................................................................................37

6.6 Electrovalves in hydraulic unit............................................................................................38

6.7 Starting hydraulic unit in automatic mode.........................................................................38

6.8 Upper roll height adjustement .............................................................................................39

6.9 Manual valves in hydraulic unit...........................................................................................40

6.10 Using hydraulics in maintenance........................................................................................41

6.11 Regular maintenance............................................................................................................47

6.12 Safety......................................................................................................................................47