C

on

ten

t

s

Chapter I: Product Introduction

1. Product Characteristics ...............................................................................................01

2. Main Applications ........................................................................................................02

3. Battery Construction ....................................................................................................02

4. General Specification ..................................................................................................03

5. VRLA Technology ........................................................................................................04

Chapter II: Electrical Characteristics

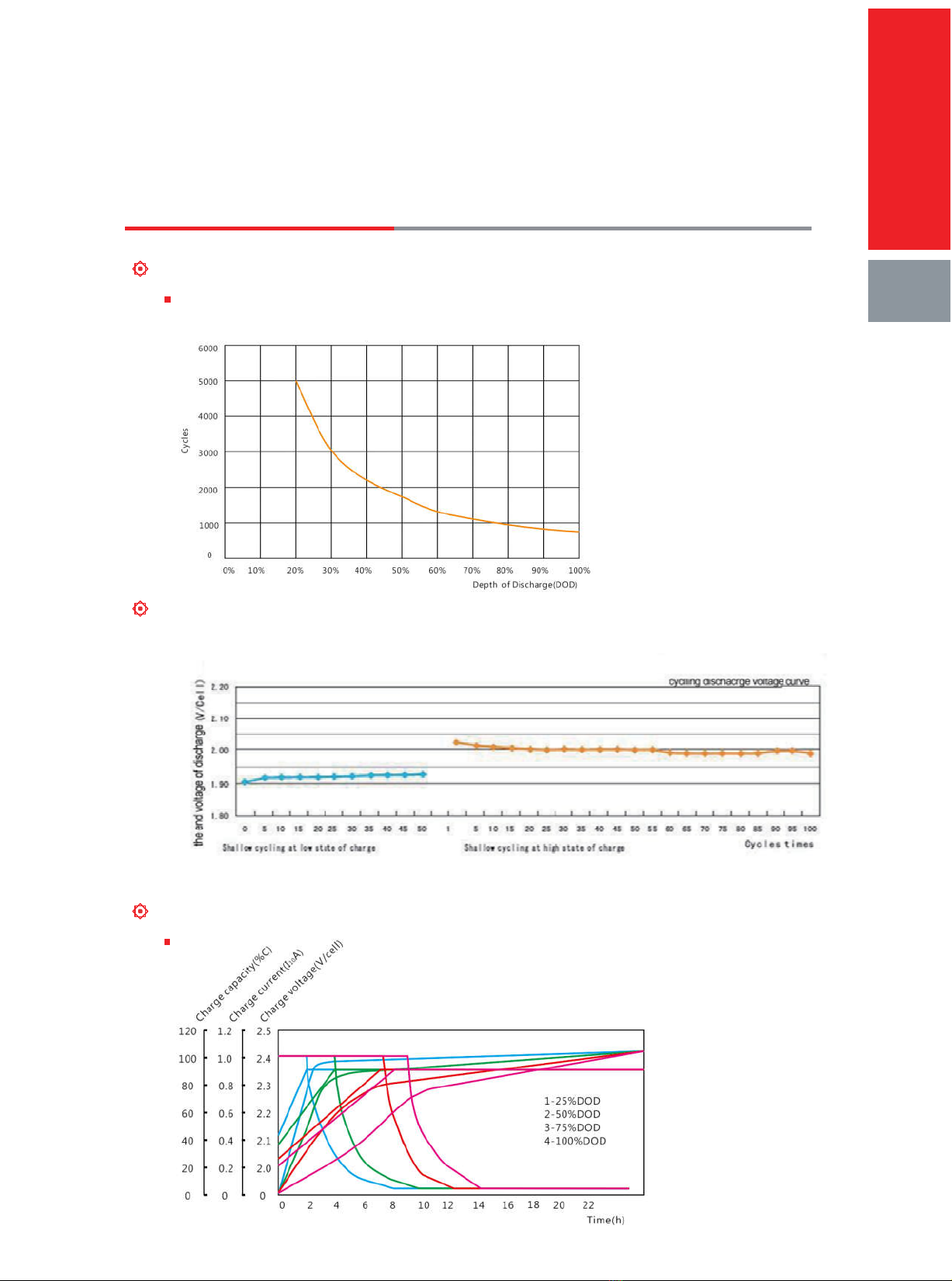

1. Performance Curve ...................................................................................05

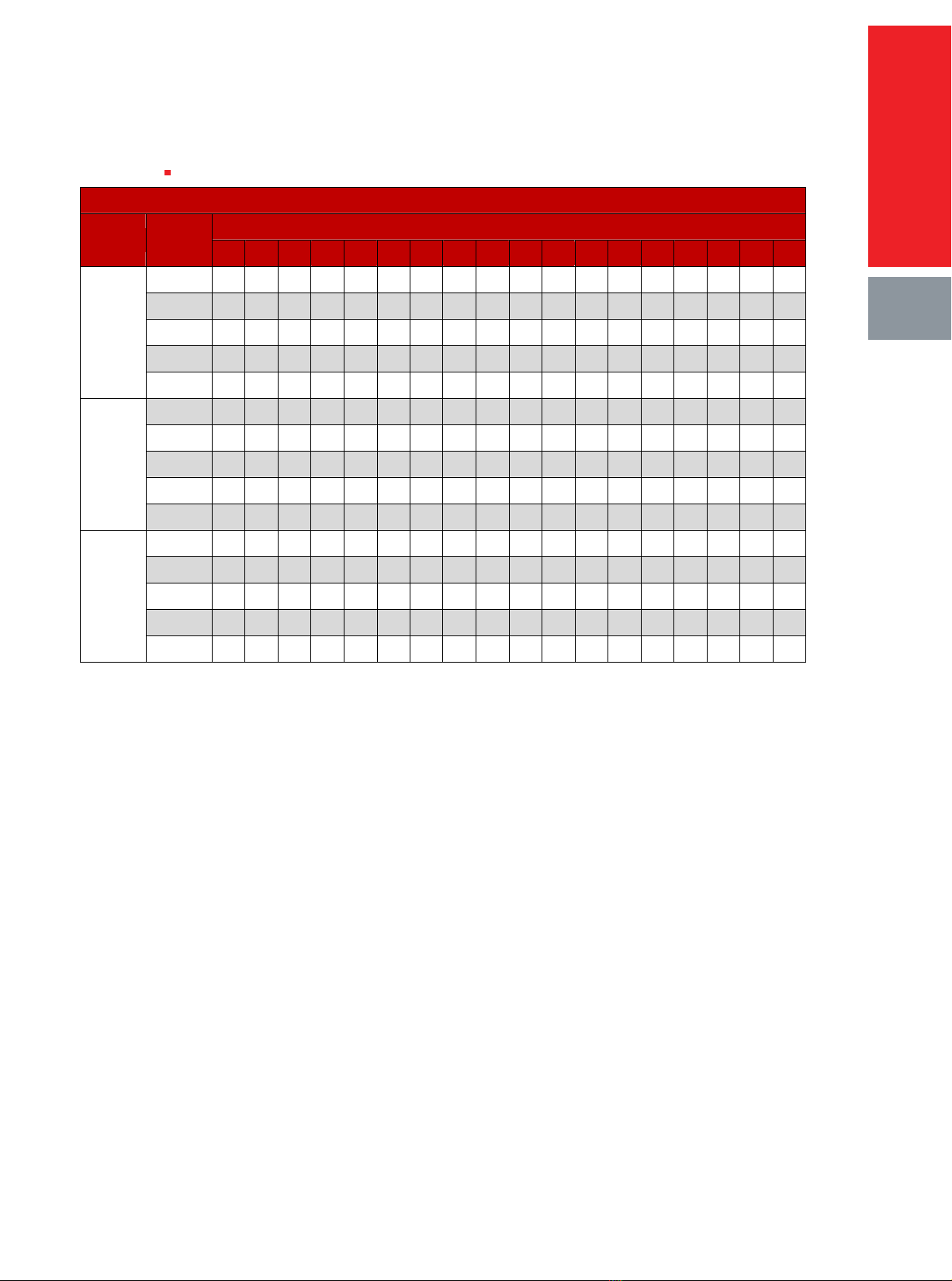

2. Performance Data ........................................................................................................06

Chapter III: Operation and Maintenance

1. Security Instruction ......................................................................................................09

2. Discharge.................................................................................................10

3. Temperature Effect On Battery Capacity .........................................................10

4. Temperature Effect on Battery Service Life.....................................................11

5. Floating Charge And Equalizing Charge .........................................................11

6. Recharge .................................................................................................13

7. Storage..................................................................................14

8. Installation ................................................................................................14

9. Connection ...............................................................................................14

10. Commissioning .........................................................................................15

11. Maintenance .............................................................................................15