C

on

ten

t

s

Chapter I: Product Introduction

1. Product Characteristics ...............................................................................................01

2. Main Applications ........................................................................................................02

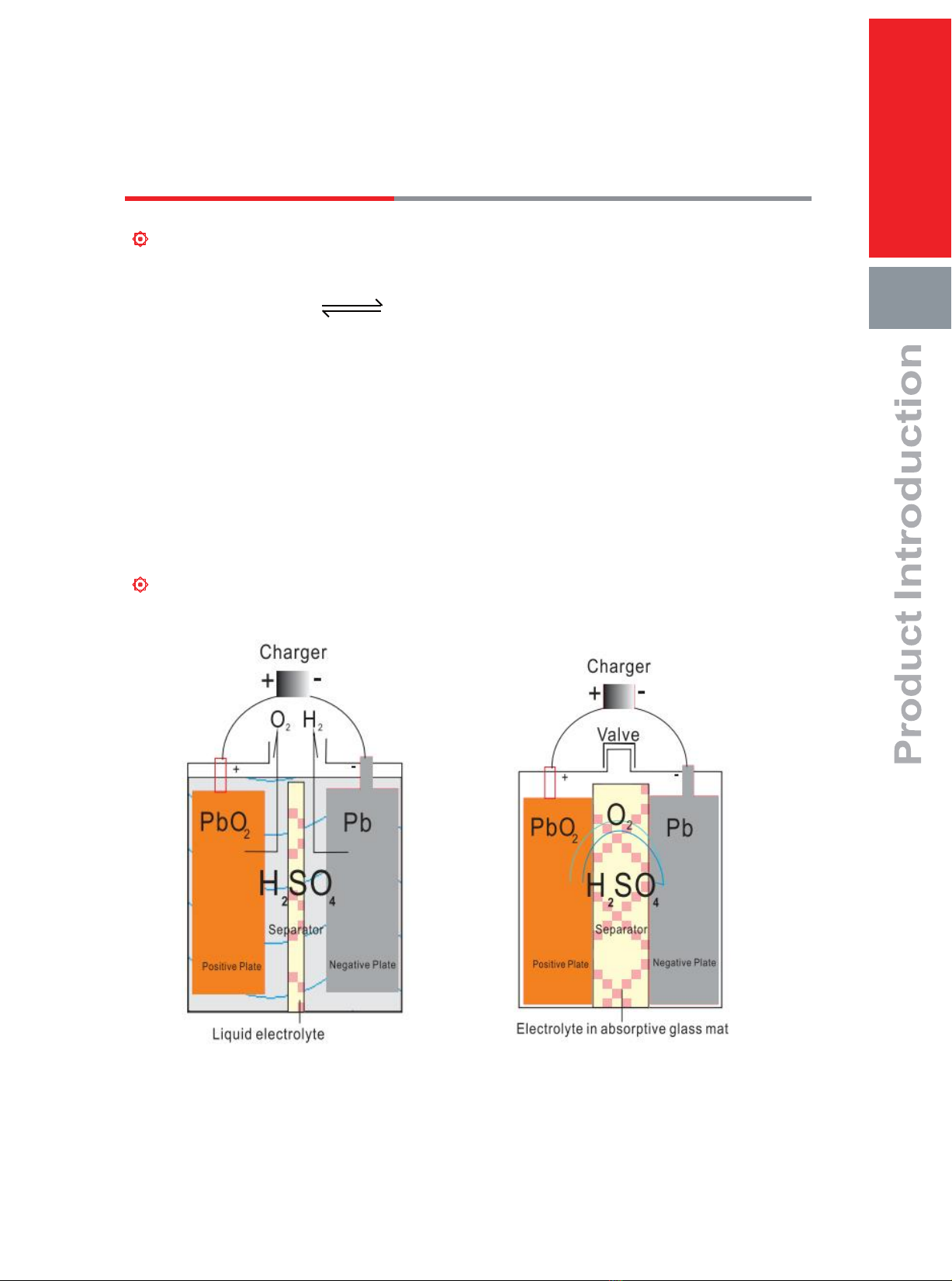

3. Battery Construction ....................................................................................................02

4. General Specifications .................................................................................................03

5. Working Principle ........................................................................................................04

Chapter II: Electrical Characteristics

1. Discharge Curve ..........................................................................................................05

2. Charge Curve ..............................................................................................................06

Chapter III: Operation and maintenance

1. Safety Instructions......................................................................................07

2. Operating Conditions and parameters .........................................................................08

3. Factors Influencing Capacity .........................................................................10

4. Temperature Effect on Battery Capacity ........................................ ..........................10

5. Recharge ............................................................................................11

6. Temperature Effect on Battery Design Life ..........................................................12

7. Charge Requirement ..................................................................................13

8. Storage.....................................................................................................13

9. Maintenance..............................................................................................15