M.HIST.0138.23 R1 Page 3 of 28 October, 06 th 2020

INDEX

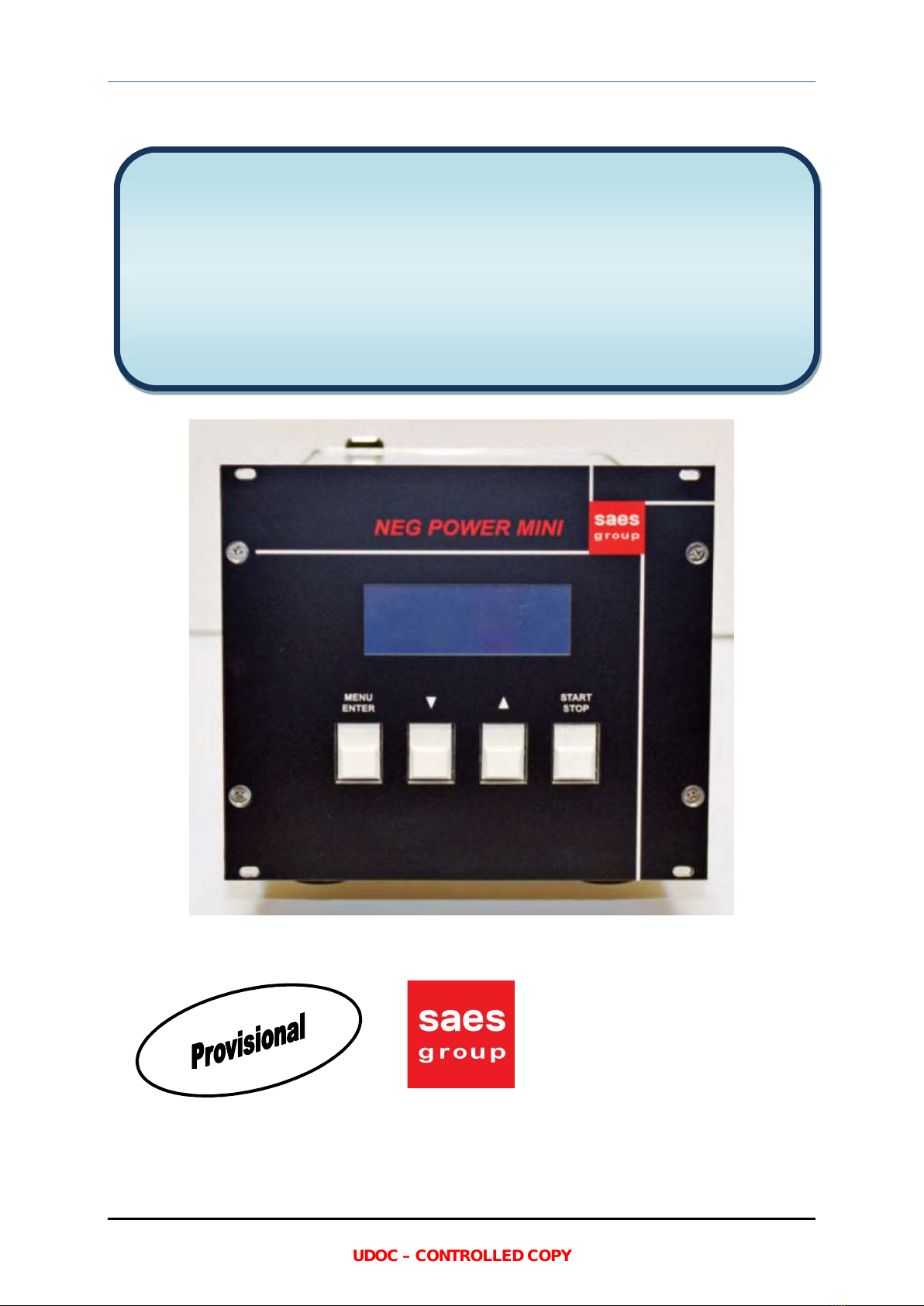

1. APPLICATION ........................................................................................ 4

2. INTRODUCTION .................................................................................... 4

2.1. General description .......................................................................... 4

2.1. Main Features .................................................................................. 5

2.2. Electronic circuit features ................................................................. 5

2.3. Remote and multi Control ................................................................ 5

2.4. The front panel of the unit ................................................................ 6

2.5. The rear panel of the unit ................................................................. 6

2.6. NEG POWER MINI Dimensions and Weight .................................... 7

2.7. Supplied accessories ....................................................................... 7

3. INSTALLATION ...................................................................................... 8

3.1. Rack mounting ................................................................................. 8

3.2. Electrical connections ...................................................................... 8

3.3. Cleaning .......................................................................................... 8

4. USAGE ................................................................................................... 9

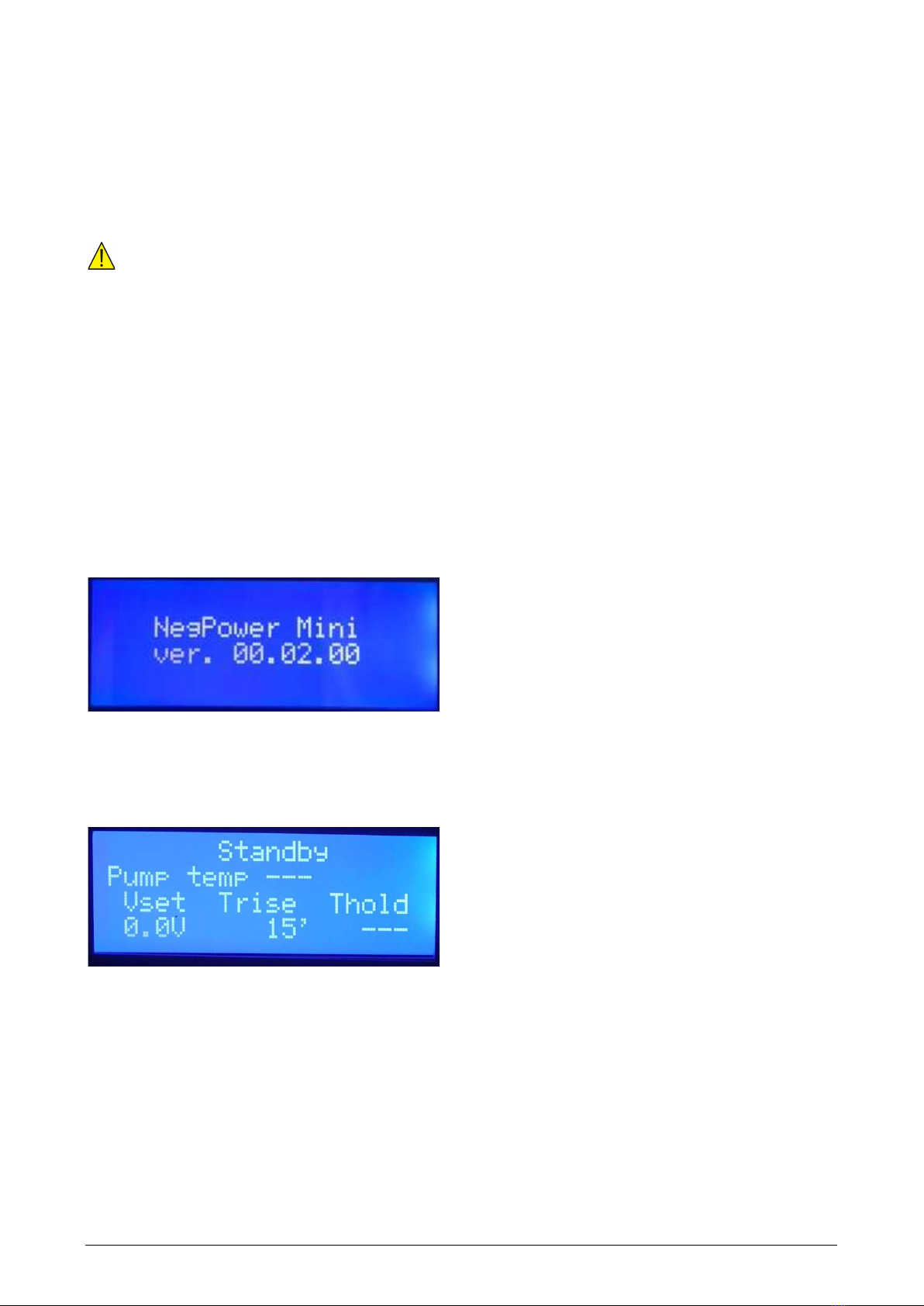

4.1. Initial setup ...................................................................................... 9

4.2. Setting Menu ................................................................................. 11

4.3. Maximum Allowed Pump Temperature .......................................... 12

4.4. Logging .......................................................................................... 12

5. ABNORMAL SITUATION AND ALARM NOTIFICATION ...................... 13

5.1. INTERLOCK Alarm ........................................................................ 13

5.2. PUMP OPEN Alarm ....................................................................... 14

5.3. OVER CURRENT Alarm ................................................................ 14

5.4. PUMP OVER TEMPERATURE Alarm ........................................... 14

5.5. VMON - UNDER VOLTAGE - OVER VOLTAGE ........................ 15

6. RECOMMENDED SETTINGS .............................................................. 16

6.1. Voltage level for the correct heating ............................................... 16

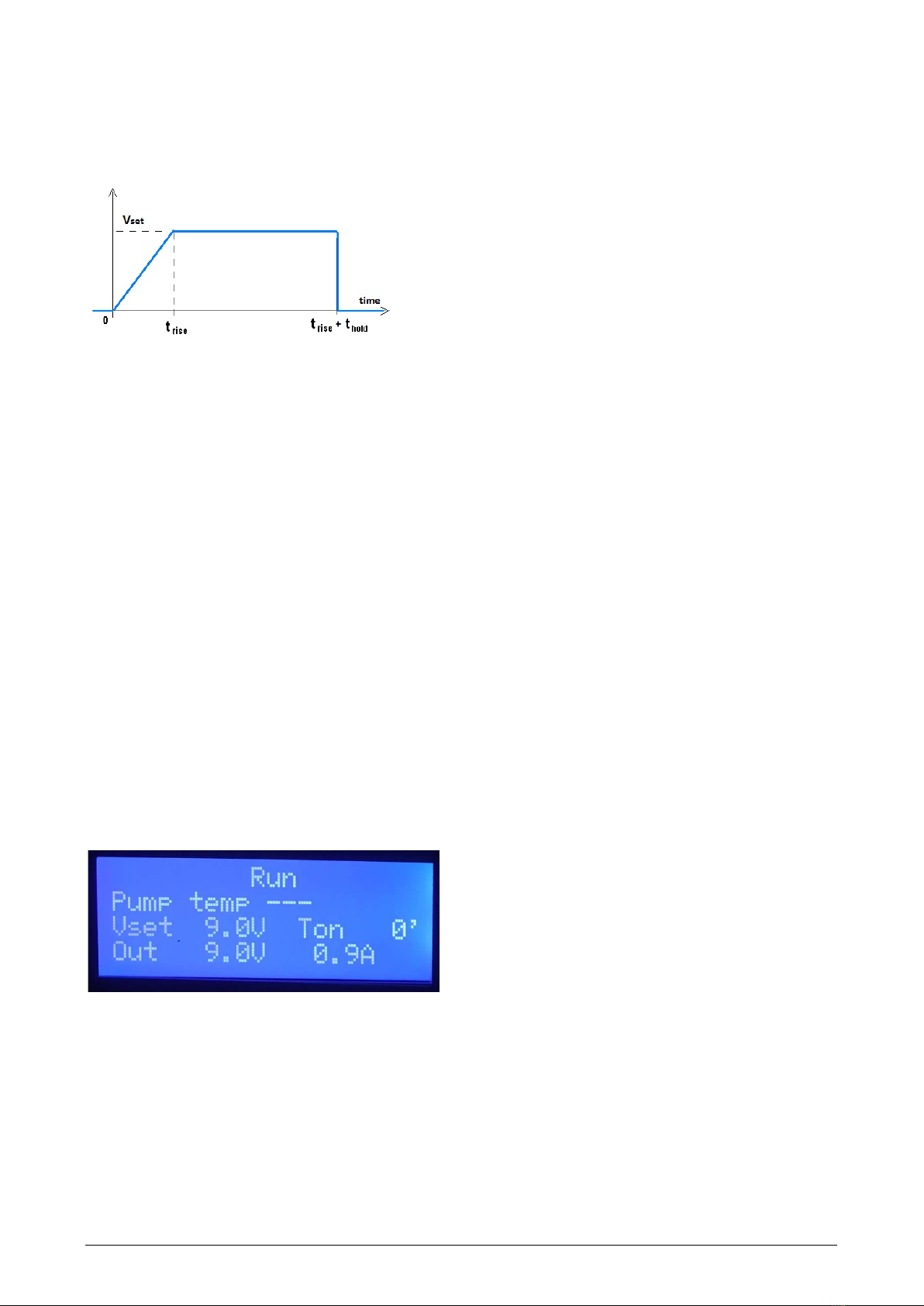

6.2. Slow Heating.................................................................................. 18

6.3. Heating without automatic stop ...................................................... 18

7. THE OUTPUT CONNECTOR FUNCTION ............................................ 19

7.1. Pin layout of DB9 IN/OUT Interface connector ............................... 19

8. ELECTRICAL SPECIFICATIONS ......................................................... 20

9. MAINTENANCE ................................................................................... 20

10. PRODUCT CONFIGURATIONS AND ACCESSORIES ........................ 21

10.1. NEG POWER MINI configurations and accessories: ................... 21

10.2. Pump cables and accessories: .................................................... 21

11. INSTRUCTION FOR INSTRUMENT DISPOSAL .................................. 22

12. WARRANTY CONDITIONS .................................................................. 23

13. SERVICE .............................................................................................. 24

13.1. Sales & Service Locations: ......................................................... 24

APPENDIX A: Supply cables ....................................................................... 25