USER GUIDELINES

CAUTION

· Please consider the safety of patient first and take care during the product operating.

· Only qualified person in dental surgery can be allowed to use the product.

· Please purchase the battery recommended by manufacturer and take care of the usage manual of

battery manufacturer before use it for the product.

· Do not use the machine with the file which is bended, damaged, deformed and/or not in ISO standard,

otherwise, it might cause injury by some possible fragments.

· Do not place or maintain the battery in the place in high temperature such as the place exposed to

direct sunlight, inside of a car in high temperature or beside of stove and fire and so on.

· Please take care of shaving, vibration, noise and heat of the product before use and test by rotating

naturally. Stop to use the product if fell abnormal condition of the product and contact to representative.

· Keep bur or file clean, otherwise dust might cause poor chucking power and it may cause vibrations during operation.

· Before changing the head or bur, turn off the power of the motor handpiece. Changing it during

power on may cause unintended rotation by accidental activation of the ON/OFF button.

· When inserting the motor handpiece into the battery charger, position the handpiece correctly.

Pushing it into the charger forcibly in the incorrect direction may cause damage.

· Take care not to put needle, pin into the charging terminal of the battery charger.

· Place the motor handpiece into the charger after clean the liquid or dust off. If the charging terminal is

in dirty, it can be rusted and cannot be charged properly.

· Users are responsible for operation, maintenance and inspection.

· Applications of machine is restricted by this manual and not-recommended applications by

a manufacturer should be avoided.

· Keep the speed of the usage tool as recommend by tool manufacturer. The excess speed limitation

might cause the accident.

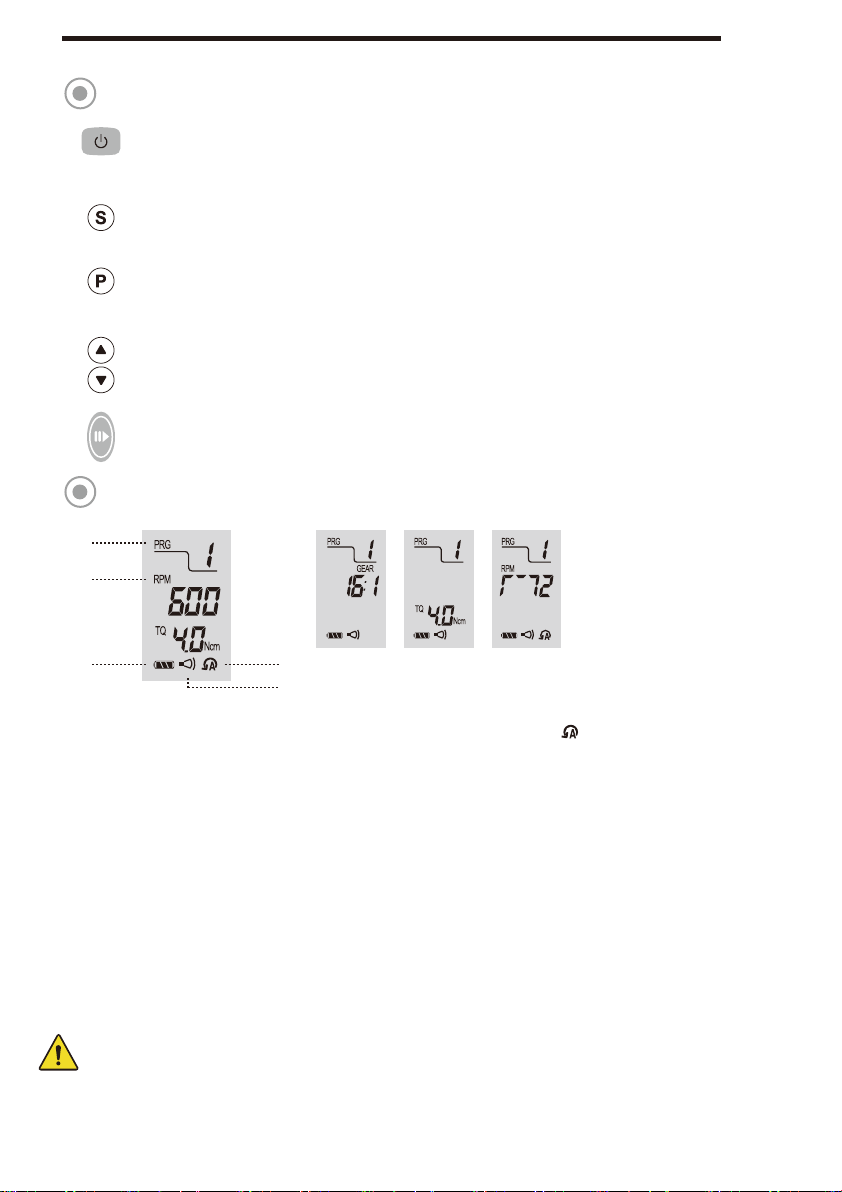

· Contact dealer when display shows wrong message, it might cause an accident.

· Only recommended product and consumable parts by manufacturer have to be used with the product,

otherwise, it may cause the accident.

· Manufacturer may change specification and design of this product in order to improve the quality.

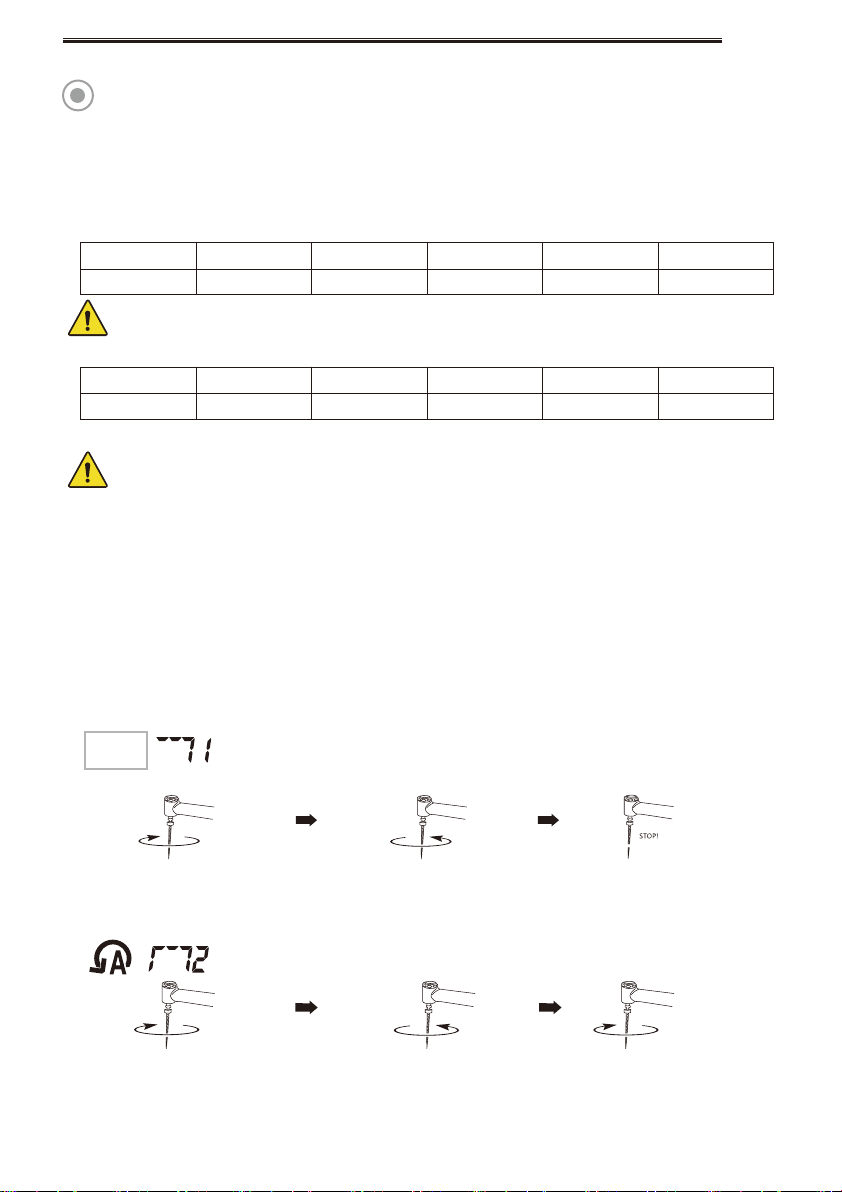

· Before use, please check if the control unit has set the gear ratio to match with the gear ratio in the contra angle.

· If motor operating speed is too fast or stop during operation, contact dealer.

· Take care not to drop or damage the motor and contra angle handpiece. Do not operate the product if

product is not operated properly after drop on the floor or water, contact the head office or dealer.

That case may cause bur vibration, excessive heat and damage to the ball bearings.

2