Sagem Ultima 600 User manual

SRef.: 21821085-0/A

Issue 02/99 1-1

S

MAINTENANCE MANUAL

AFTER SALES DEPARTMENT

ZI Route de MAMERS

72405 LA FERTE-BERNARD - France

Tel.: 02 43 60 43 60 - Fax: 02 43 60 43 61

Printed in France; total or partial reproduction prohibited without prior written authorization. The information contained in this

document is subject to change without prior notice and cannot be understood under any circumstances as contractually binding.

.

ULTIMA 600

SRef.: 21821085-0/A

Issue 05/99 1-2

SECTION 1 – PRELIMINARY PAGES

TABLE OF CONTENTS

SECTION 2 UNPACKAING / COMMISSIONING.................................................. 2-1

2.1 - UNPACKAGING THE UNIT......................................................................................2-1

2.1.1 - Opening the cardboard boxes........................................................................................... 2-1

2.1.2 - Setting up the unit ............................................................................................................. 2-2

2.1.3 - Installing the printer paper................................................................................................. 2-3

2.1.4 - Installing the tubes ............................................................................................................ 2-3

2.1.5 - Installing the tightness fitting............................................................................................. 2-5

2.1.6 - Initial startup...................................................................................................................... 2-5

SECTION 3 DESCRIPTION / OPERATION .......................................................... 3-1

3.1 - GENERAL INFORMATION.......................................................................................3-1

3.2 - DESCRIPTION OF FRONT PANEL..........................................................................3-1

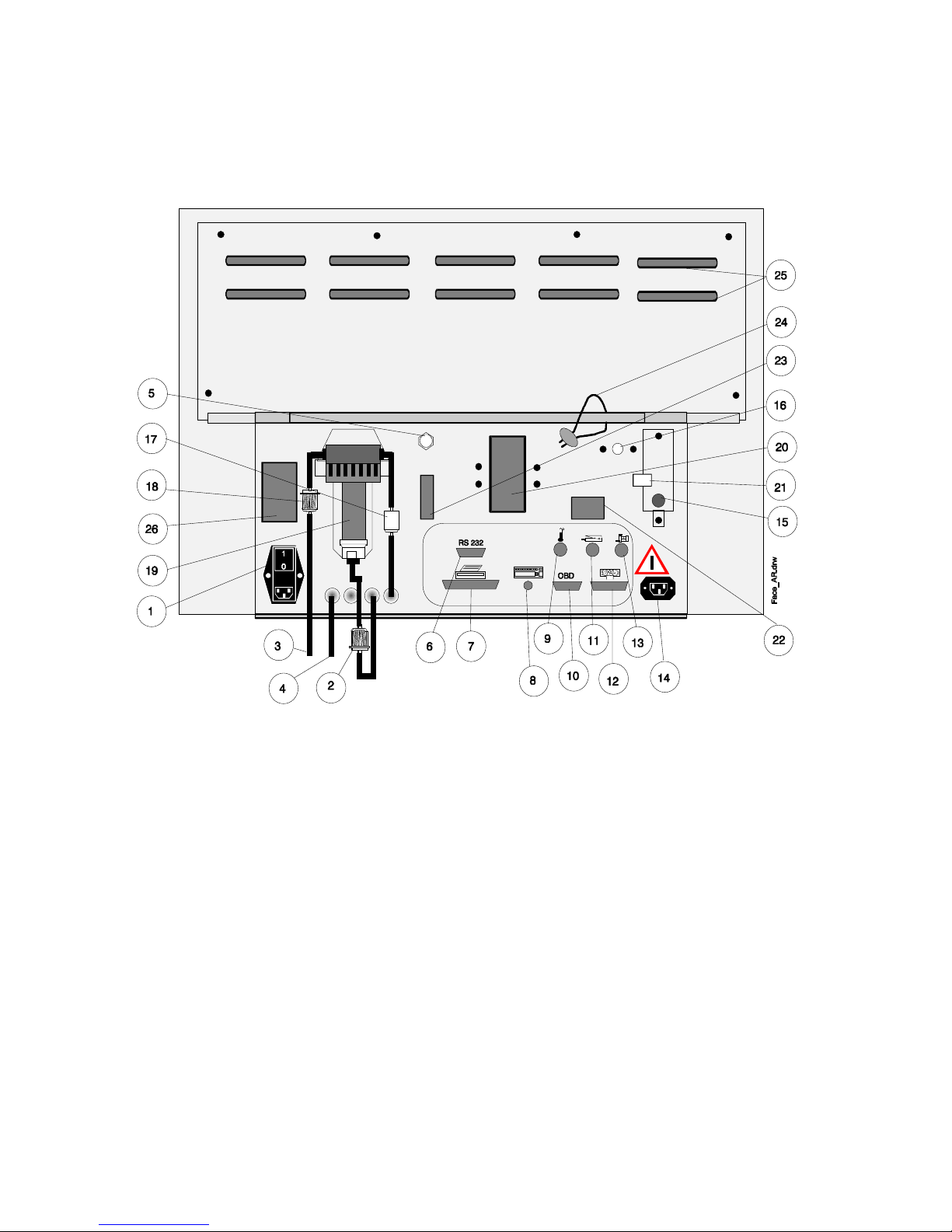

3.3 - DESCRIPTION OF REAR PANEL............................................................................3-4

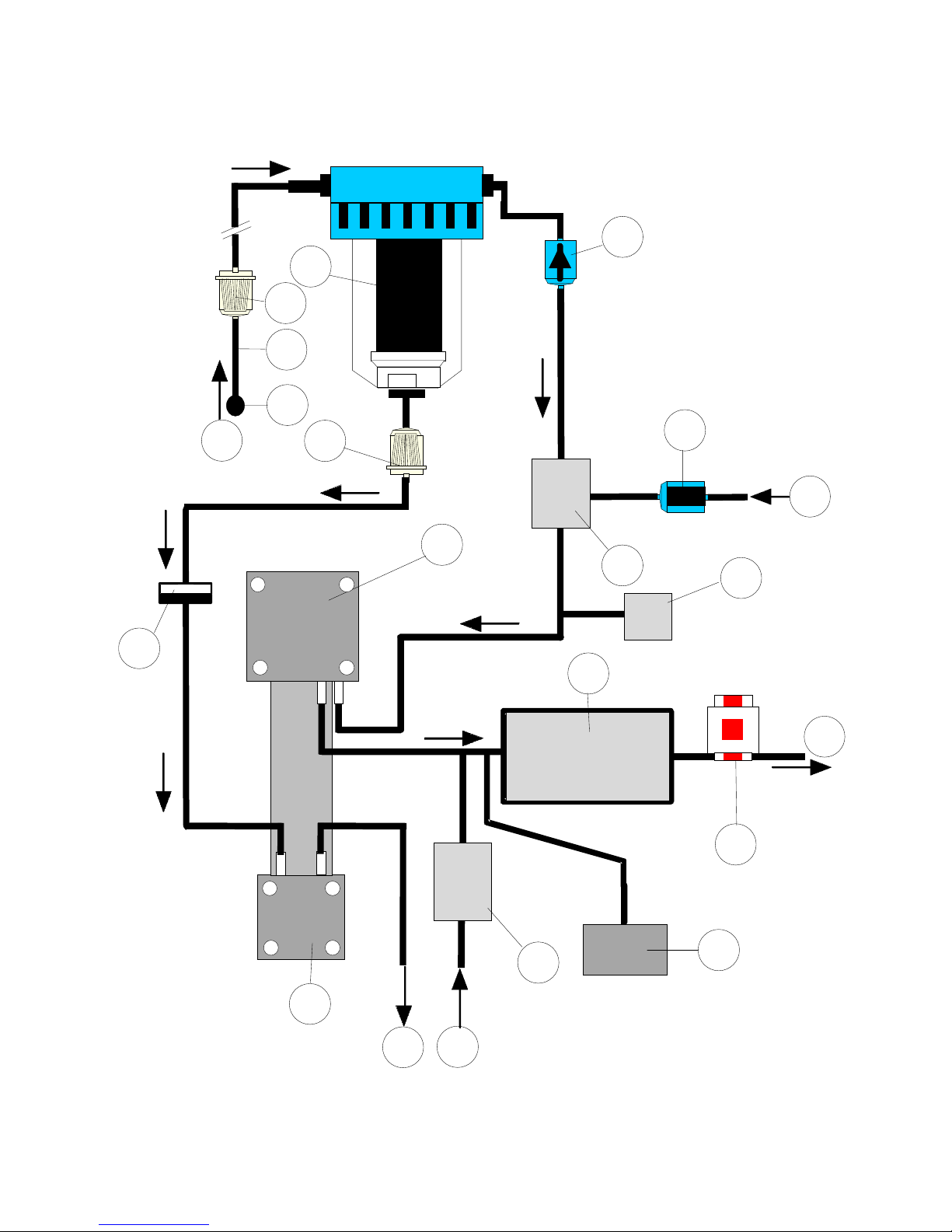

3.4 - DESCRIPTION OF PNEUMATIC CIRCUIT ..............................................................3-6

SECTION 4 PREVENTIVE MAINTENANCE......................................................... 4-1

4.1 - « GAS » MODE CUSTOMER SELFTEST ................................................................4-1

4.1.1 - Tightness test.................................................................................................................... 4-1

4.1.2 - Version, CS, FEP .............................................................................................................. 4-3

4.1.3 - Lambda control ................................................................................................................. 4-3

4.1.4 - HC residue test ................................................................................................................. 4-4

4.1.5 - Adjustement information ................................................................................................... 4-5

4.1.6 - Cell status.......................................................................................................................... 4-5

4.1.7 - Cleaning the unit and its accessoires.................................................………….................4-7

4.1.4 - Filter .................................................................................................................................. 4-7

4.1.5 - O2 cell ................................................................................................................................ 4-7

4.2 - « SERVICE » MAINTENANCE MODE......................................................................4-8

4.3 - « OPACITY » MODE CUSTOMER SELFTEST ......................................................4-11

SECTION 5 CORRECTIVE MAINTENANCE........................................................ 5-1

5.1 - SOFTWARE ..............................................................................................................5-1

5.1.1 - 1 point adjustment test ...................................................................................................... 5-1

5.1.2 - 2 point adjustement test: ................................................................................................... 5-5

5.1.3 - Replacement of O2 sensor .............................................................................................. 5-10

5.1.4 - Negative values selftest .................................................................................................. 5-12

5.1.5 - Downloading the software :............................................................................................. 5-14

5.1.6 - Downloading a new boot and a provisional application.................................................. 5-16

SRef.: 21821085-0/A

Édition 05/99 1-3

5.2 - HARDWARE ...........................................................................................................5-18

5.2.1 - Replacing fuses............................................................................................................... 5-18

5.2.2 - Replacing filters............................................................................................................... 5-18

5.2.3 - Disassembly of rear cover............................................................................................... 5-20

5.2.4 - Disassembly of equipped unit ......................................................................................... 5-21

5.2.5 - Disassembly of pump...................................................................................................... 5-22

5.3 - EXTENDED ACCESS .............................................................................................5-23

5.3.1 - Reading indicators .......................................................................................................... 5-23

5.2.2 - Installing the opacimeter option ...................................................................................... 5-24

SECTION 6 SPARE PARTS CATALOGUE......................................................... 6-1

SECTION 7 TECHNICAL MODIFICATIONS RECORD ....................................... 7-1

SECTION 8 LIST OF DRAWINGS ........................................................................ 8-1

SRef.: 21821085-0/A

Issue 05/99 1-4

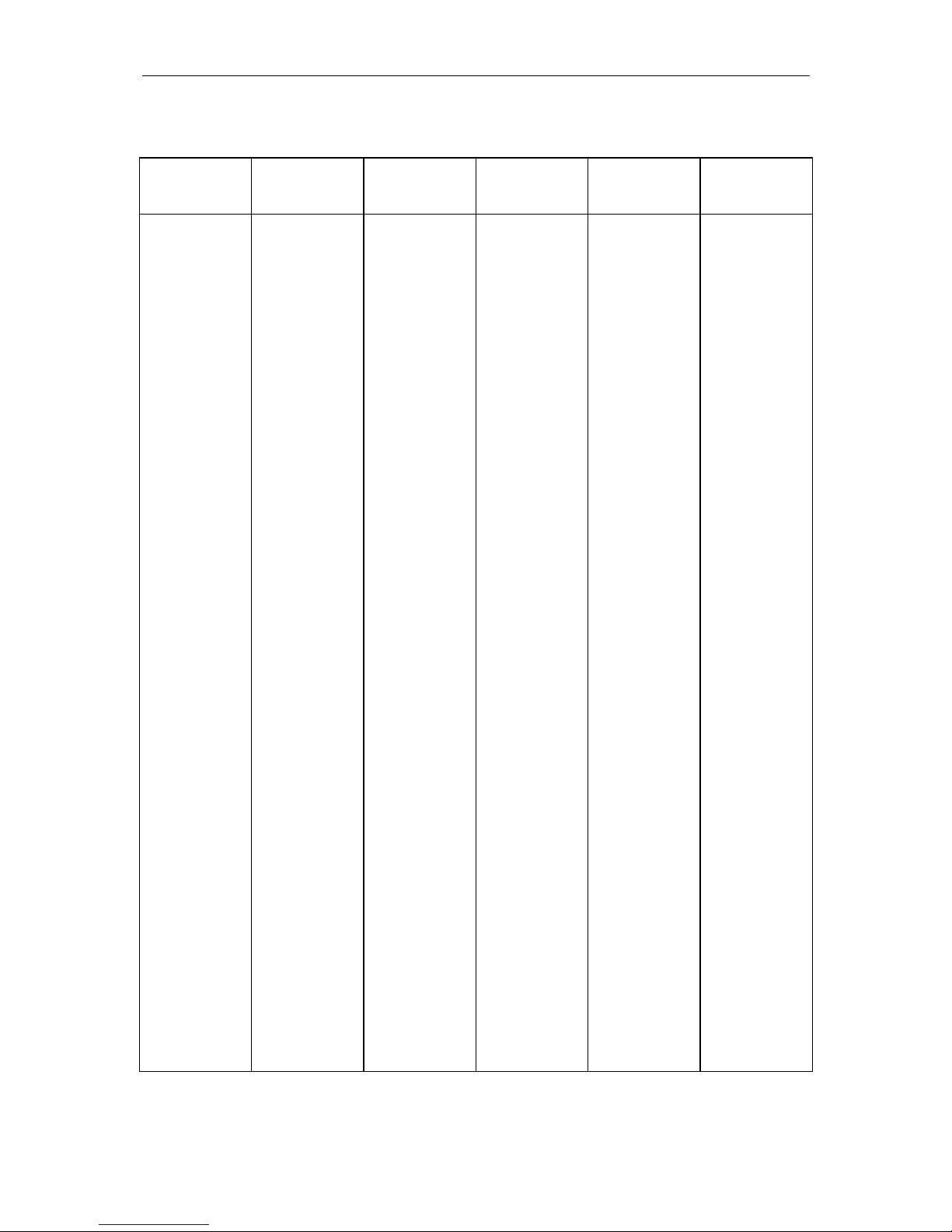

REVISION INDEX

PAGE No. DATE OF

ISSUE

PAGE No. DATE OF

ISSUE

PAGE No. DATE OF

ISSUE

1-1

1-2 to 1-5

1-6

2-1 to 2-4

2-5

2-6

3-1 to 3-10

4-1 to 4-13

5-1 à 5-22

5-23 à 5-25

6-1

6-2

6-3 to 6-4

6-5

6-6

6-7

02/99

05/99

02/99

02/99

05/99

02/99

02/99

05/99

02/99

05/99

02/99

05/99

02/99

05/99

02/99

05/99

SRef.: 21821085-0/A

Édition 05/99 1-5

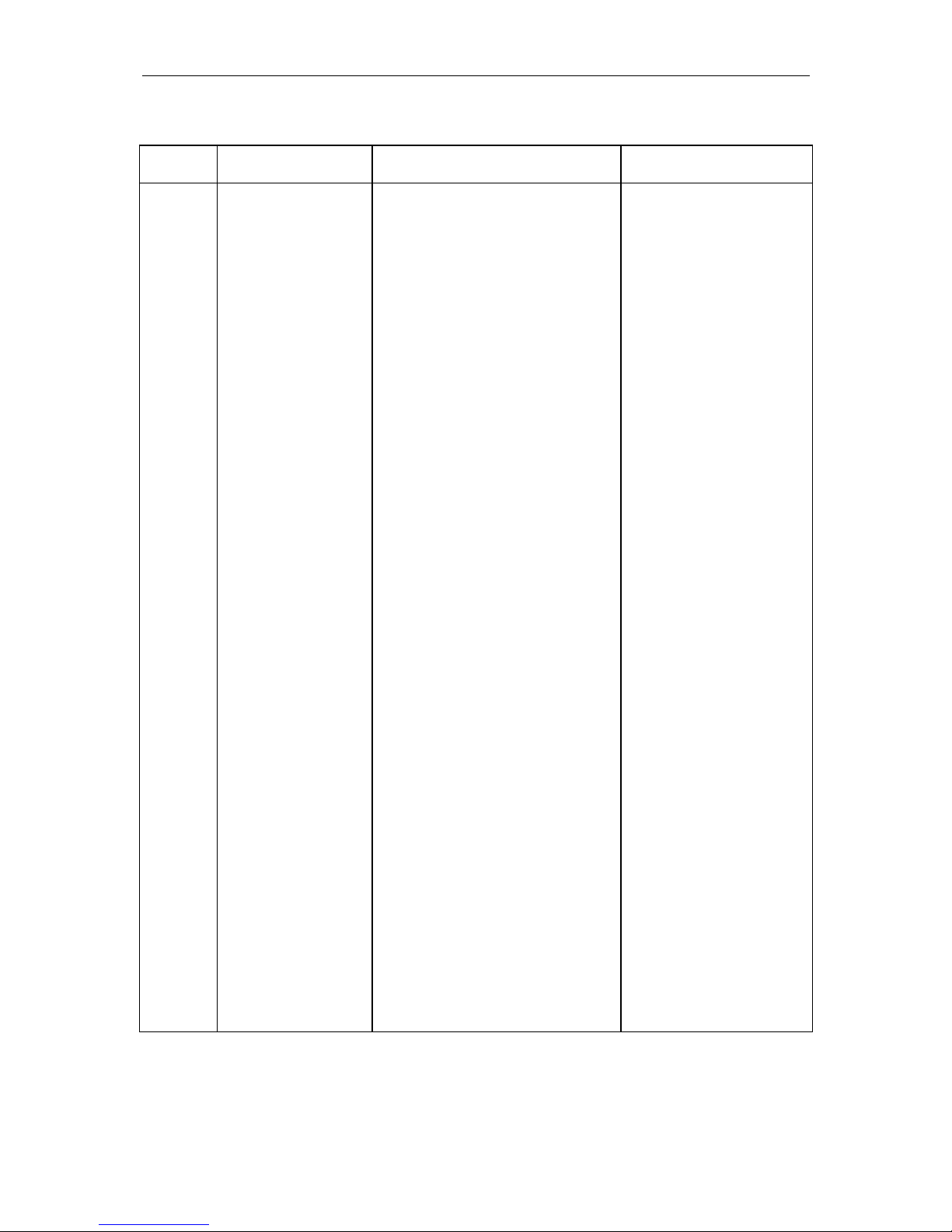

UPDATE RECORD

No. REFERENCE REMARKS UPDATE

1

Opacimeter modifications MAY 12, 1999

SRef.: 21821085-0/A

Issue 05/99 1-6

FIGURES AND DRAWINGS

SECTION 2

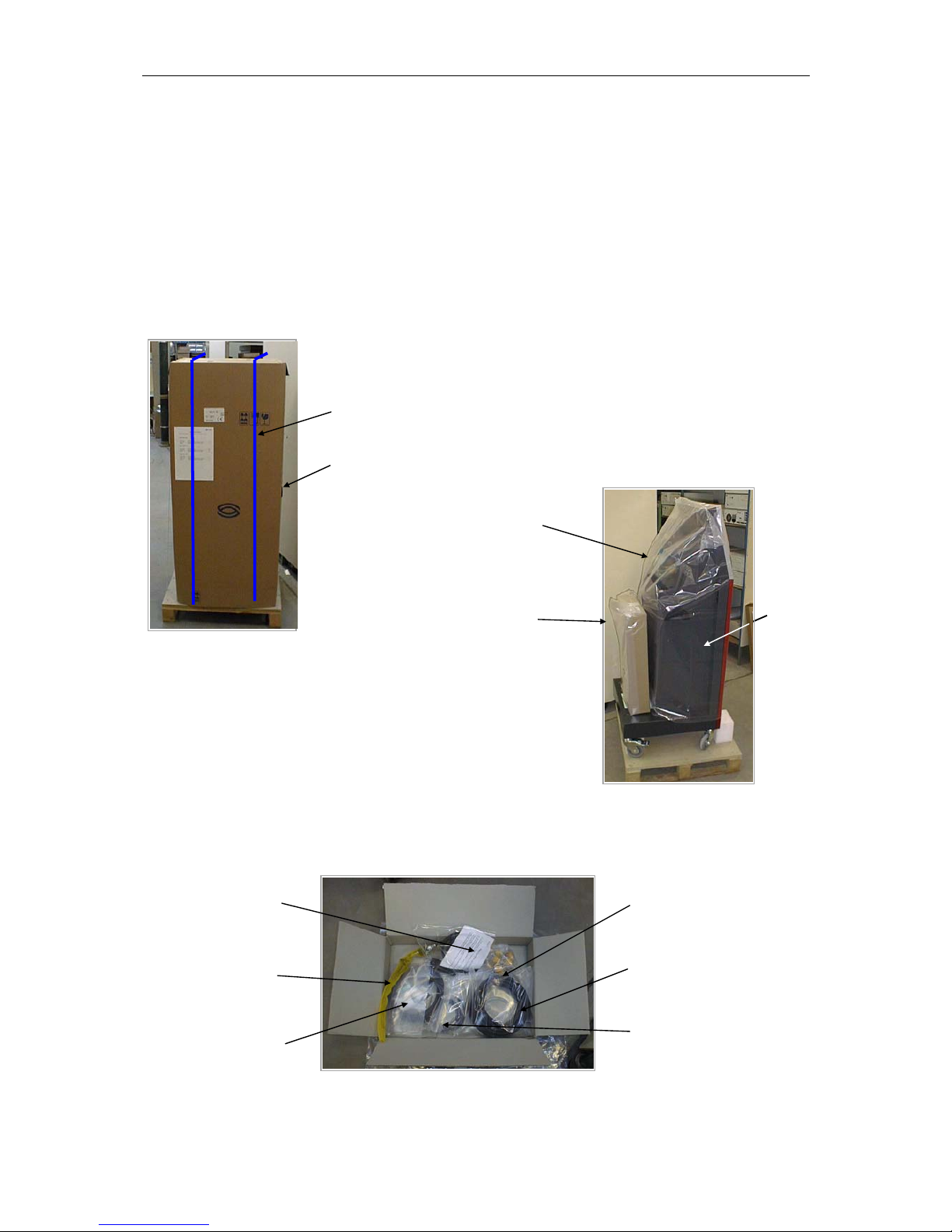

Figure 2.1 - ULTIMA 600 in its package

Figure 2.2 - ULTIMA 600 with cardboard box removed

Figure 2.3 – Accessory box

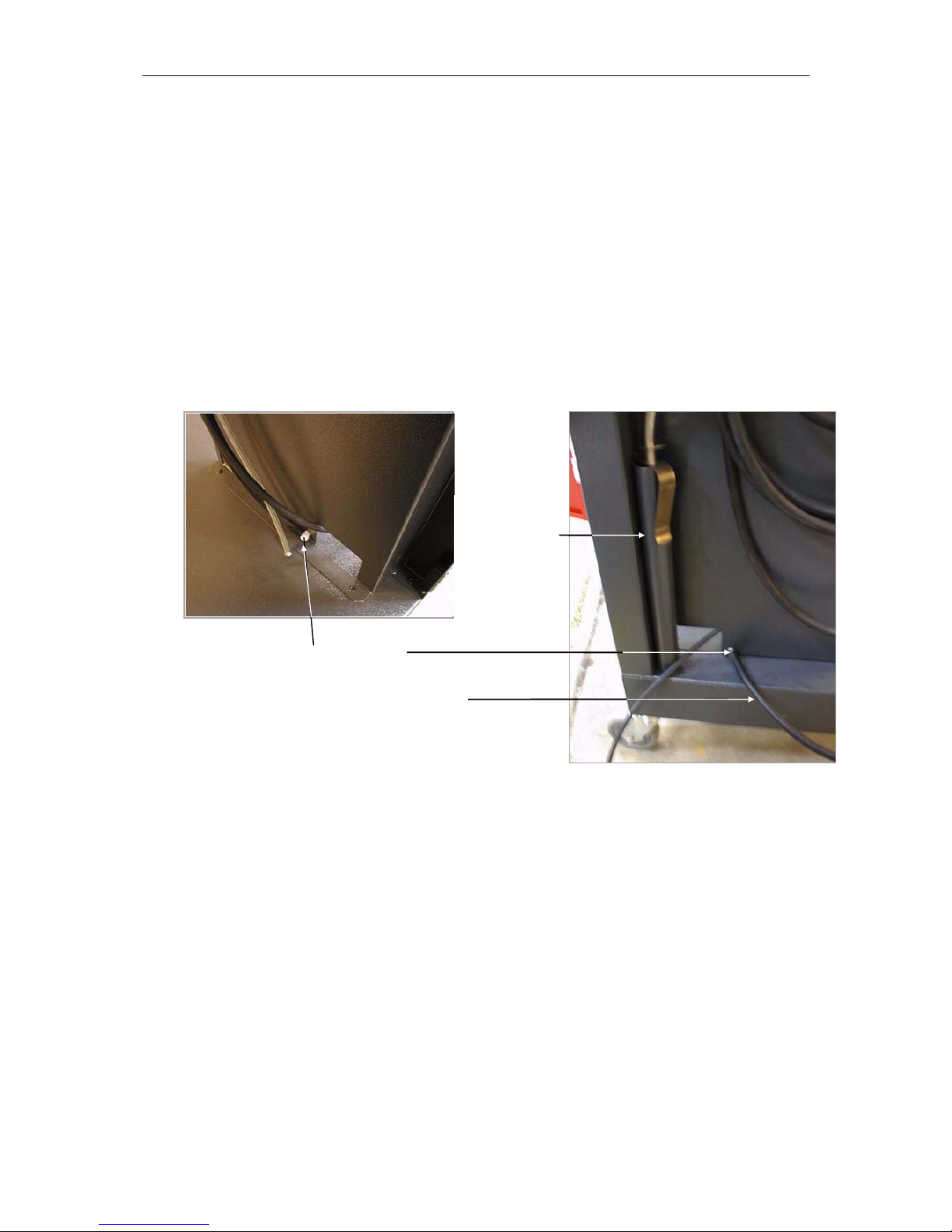

Figure 2.4 – Storage compartment for documents supplied with unit

Figure 2.5 – Installing the printer paper

Figure 2.6 - ULTIMA 600 / Rear panel

Figure 2.7 – Installing gas sampling sensor

Figure 2.8 – Power up

Figure 2.9 – Pre-heating screen

SECTION 3

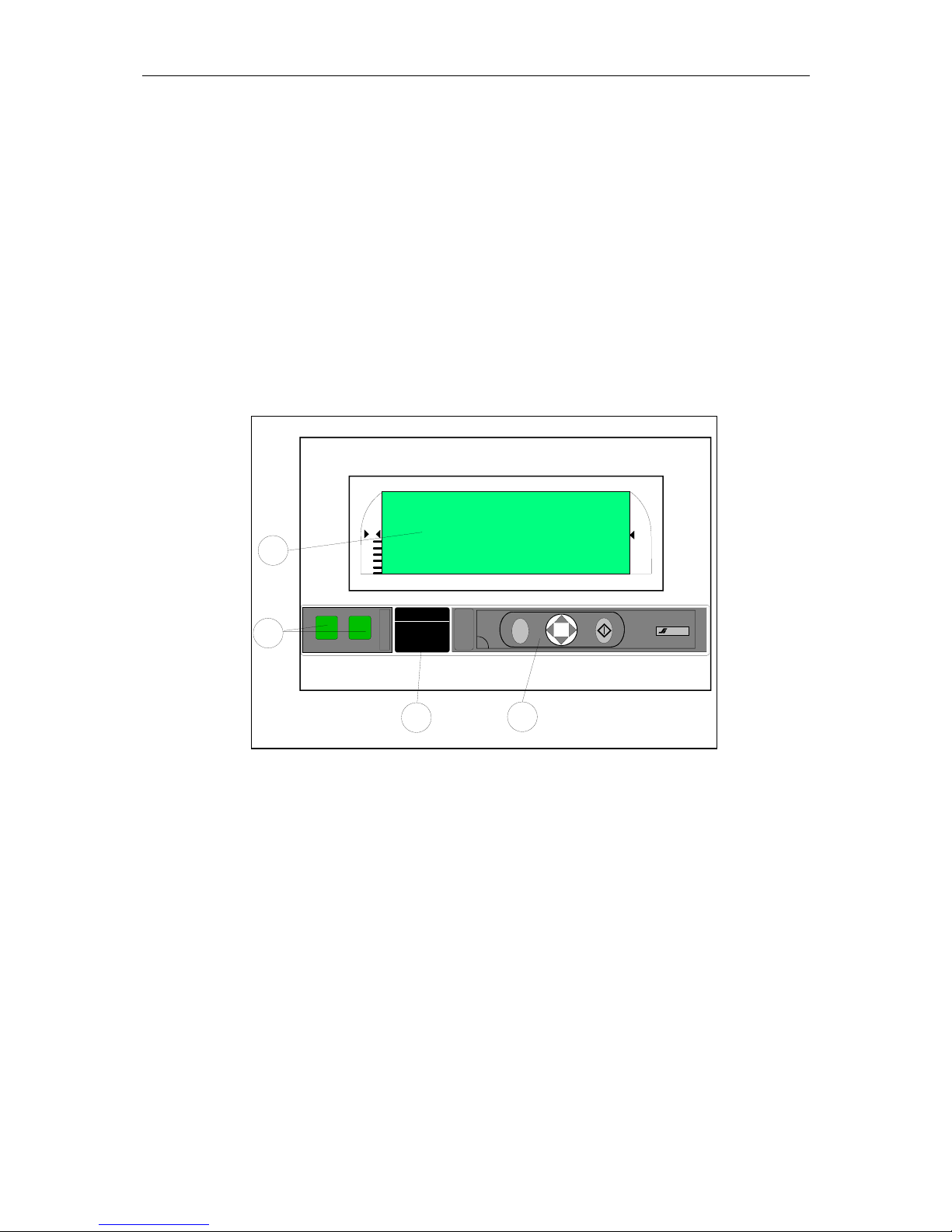

Figure 3.1 - ULTIMA 600 / Front panel

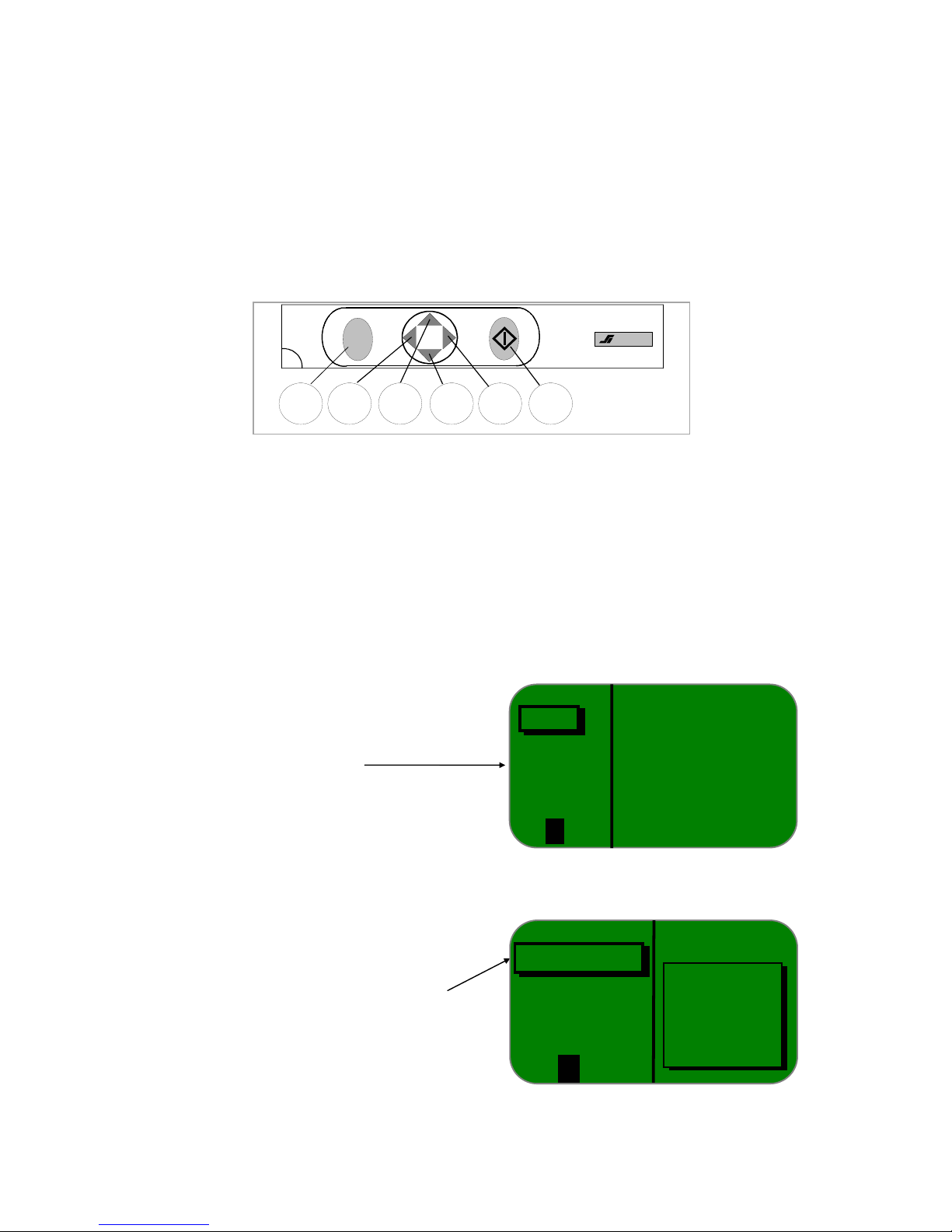

Figure 3.2 – 6-key keypad

Figure 3.3 – Sequence of screens to reach self-test

Figure 3.4 - ULTIMA 600 / Rear panel

Figure 3.5 – Pneumatic circuit

SECTION 4

Figure 4.1 – Tightness test – Display screens

Figure 4.2 – HC residue test – Display screens

SECTION 5

Figure 5.1 – Internal component locations

Figure 5.2 – Connector locations

Figure 5.3 – Cleaning and replacement of pump seal

SECTION 8

SRef.: 21821085-0/A

Édition 05/99 1-7

sRef.: 21821085-0/A

Issue 02/99 2-1

SECTION 2

UNPACKAGING - COMMISSIONING

2.1 - UNPACKAGING THE UNIT

2.1.1 - Opening the cardboard boxes

Figure 2-1 - ULTIMA 600

in its package

5. Open the accessory box on the top

(Cut the adhesive paper using a cutter).

6. Open the plastic bag containing the accessories

using a pair of scissors.

7. Check the contents of the box (Fig. 2-3).

Lock

Retainer

1. Cut the plastic retainers.

2. Unlock the lock (fig. 2-1).

3. Remove and fold the cardboard box.

4. Remove the accessory box at the rear

of the unit. (fig. 2-2)

Sampling

Sensor

Power cable

with printer

roll

Gas sampling

tube

Oil T°

sensor

Gasoline

engine speed

sensor

Spare filters

Figure 2-3 - Accessory box

Figure 2-2 - ULTIMA 600

with cardboard box

removed

ULTIMA 600

Accessory box

Plastic

envelope

SRef.: 21821085-0/A

Issue 02/99 2-2

Figure 2-4 - Storage compartment for

documents supplied with unit

8. Lower the unit off the pallet.

9. Stow the pallet.

10. Using a cutter, remove the plastic envelope from the unit.

11. Remove the adhesive protections from the screen and panel.

12. Open the trolley door (fig. 2-4) and check for:

- the warranty voucher,

- the user manual (Ref. 218200705),

- the metrology book.

2.1.2 - Setting up the unit

Work area:

The ULTIMA 600 must be placed:

- near a 230 volts / 50 Hertz / + ground power outlet.

- in a clean, non-corrosive atmosphere; avoid:

. body work preparation areas (sanding, paint),

. battery storage or replacement rooms,

. areas in the vicinity of gasoline flowmeters, washing gantries

. exposure to weather.

Operating temperature range:

+5 °C to +40°C.

Outside these limits, the unit is no longer under normal operating conditions.

Safety:

The power cable must be easily accessible and connected near the unit.

Note: The metrology book must always

be kept available to the government

authorities and certified inspectors. This

book contains information relative to

verification and repair of the unit.

- Garanty voucher,

- User manual

- Metrology book

sRef.: 21821085-0/A

Issue 02/99 2-3

2.1.3 - Installing the printer paper (fig. 2-5)

•Prepare the paper roll by removing the adhesive part (cut around 10 cm off the roll).

•Pull the printer cover lock on the front panel of the unit (to do so, grasp the lower part of

the cover between your thumb and little finger and pull out, taking care to grasp the lower

part of the lock).

•Insert the paper roll in the housing so that the end moves down naturally toward the

bottom (white side downward).

•Pull out a section of paper.

•Close the flap.

•To cut the paper, pull downwards.

Figure 2-5 - Installing the printer paper

2.1.4 - Installing the tubes (fig. 2-6)

Figure 2-6 - ULTIMA 600 / REAR PANEL

Notes: Only the treated side of the paper will be printed.

Be sure the paper roll is properly positioned.

SAGEM

C

SOURIAU

Sampling sensor

stow bracket

Power cable

stow bracket

(3) - Pump water

evacuation tube

(1) - Gas

sampling tube (4) - Gas

evacuation

tube

(6) – Temp.

sensor

(5) - Gasoline

engine speed

sensor

(2) Mains cable

SRef.: 21821085-0/A

Issue 02/99 2-4

The tubes are connected as shown in figure 2-6. Rilsan collars are provided on the frame to

guide and keep all the tubes in place.

(1) - Exhaust gas inlet (See fig. 2-7):

•Connect the 80 cm tube to the outlet of the paper filter taking care to run it through

the Rilsan collar on the frame.

•Connect the plastic 90° elbow to the 80 cm tube and to the 7 m tube coming out of

the frame by a hole provided in the lower part.

•Engage the sampling sensor on the other end.

•Roll the gas sampling tube around the bracket provided for this purpose on the left

side of the frame.

•Stow the sampling sensor in its housing.

Figure 2-7 - Installing gas

sampling sensor

(2) - Mains power cable:

•Connect the power cable to the power filter.

•Run the cable down along the frame through the hole provided for this purpose after

equipping the cable with a plastic sheath to give it a 90° angle and hold it in this

position without damaging the cable.

•Roll the cable on the lower part of the frame.

(3) - Water evacuation tube:

•The tube is already connected to the unit.

•Run the tube down along the frame, passing it through the same Rilsan collar as the

sampling sensor tube.

•Insert it in the passage provided for this purpose in the lower part of the frame.

90° elbow

Exhaust gas

inlet tube

Sampling

sensor stow

position

Inside view of

frame

External view of

frame

sRef.: 21821085-0/A

Issue 02/99 2-5

(4) - Gas evacuation tube:

•Engage the transparent tube on the « Gas evacuation » outlet (see fig. 2-6).

•Run tube through Rilsan collar provided for this purpose on frame.

•Cut the tube to the desired length.

(5) - Gasoline engine speed sensor:

•Connect the DIN connector to the gasoline engine speed sensor (see fig. 2-6).

•Roll cable on the small reel provided for this purpose on the right side of the frame.

(6) - Oil temperature sensor:

•Connect the oil temperature sensor to the DIN connector (see fig. 2-6 and 2.7).

•Stow it in the housing provided for this purpose in the frame.

2.1.5 - Installing the tightness fitting

The tightness fitting is secured to the power cable between the power connector and the

cable passage in the chassis.

2.1.6 - Initial startup

1. Connect the power cable to the mains outlet:

•General power supply : 195 - 253 Volts, 47 - 63 Hz, + ground.

•Current : 0.3 Amps

2. Start up the unit (On/Off switch set to position 1):

- Once started up, the SAGEM logo appears on the screen,

- After a few seconds: ULTIMA600 is displayed.

3. The standby screen is displayed

Figure 2-8 - Power up

S

ULTIMA 600

GAZ

OFP

OBD

Service

ULTIMA 600

GAS

SRef.: 21821085-0/A

Issue 02/99 2-6

4. Following power up, the ULTIMA 600 stays in « Preheating » mode for up to 15 minutes *

during which no measurement can be performed. During the last three minutes of

preheating in STANDBY mode, a time counter is displayed.

* The preheating time can vary:

15 minutes (unit cold)

1 to 7 minute(s) (unit hot)

5. For the remaining operations, refer to the user manual supplied with the unit.

Figure 2-9 - Preheating screen

Selftest

Service

GAS: PREHEATING

2’50

Selftest

←

SRef.: 21821085-0/A

Issue 02/99 3-1

SECTION 3

DESCRIPTION / OPERATION

3.1 - GENERAL INFORMATION

The OPTIMA 600 gas analyzer is designed to simultaneously measure the carbon monoxide

(CO), the carbon dioxide (CO2), the unburned hydrocarbons (HC) and the oxygen (O2)

contained in the exhaust gases of vehicles with positive ignition engines.

The ULTIMA 600 is also designed for use with an opacimeter option.

3.2 - DESCRIPTION OF FRONT PANEL (fig. 3-1)

Figure 3-1 - ULTIMA 600 / FRONT PANEL

(1) - Graphic display (LCD type):

•Displays operator messages and the measurement results for the four gases:

- CO, CO2, O2 in volume %

- HC in volume ppm,

- the corrected CO calculated in volume %,

- the LAMBDA (λ) parameter.

(2) - Periodic inspection labels for gas analyzer and opacimeter.

(3) - Printer

1

2

34

0

STREAM IX SYSTEM IN SIDE

C

SOURIAU

SRef.: 21821085-0/A

Issue 02/99 3-2

(4) - 6-key keypad, comprising:

- (5) Key C : exhaust or exit

- (6) Key < : move left

- (7) Key s : move up or increment

- (8) Key t : move down or decrement

- (9) Key > : move right

- (10) Key <> : validate or enter

Figure 3-2 - 6-key keypad

By pressing key (10), the unit goes into STANDBY mode; the SELFTEST and SERVICE

modes can then be accessed by key (8) and validated by key (10).

A series of options is proposed (tightness test, version CS FEP, Lambda control, calibration,

HC residue test, info and ÅReturn in the form of a scrolling menu which you can select

using keys (7) and (8).

Access and exit from a function is achieved using key (10).

To return to the standby mode, meaning exit from the SELFTEST mode, select Å.

5678910

C

SOURIAU

GAZ

OFP

OBD

Service

Å

ULTIMA 600

GAS

Standby screen

Checks that the values measured are

not diluted by air. Indicates state of

gaseous circuit from sampling sensor

up to pump (after change of filter, for

example), which is mandatory every 3

months.

SELFTEST

Tightness test

Version CS, FEP

Lambda control

Info

←

SRef.: 21821085-0/A

Issue 02/99 3-3

Figure 3-3 - Sequence of screens to reach selftest

A complete description of the various menus and their use is given in the Ultima 600 User

Manual. (Reference: 218200705)

SELFTEST

Tightness test

Version CS, FEP

Contrôle Lambda

Info

←

Checks exactness of

Calculation formula

among the various CO,

CO2, HC and O2

values (must be in the

immediate vicinity of 1).

Lambda control

SELFTEST

Tightness test

Version CS, FEP

Lambda control

Info

←

Software version,

Checksum

Cell coefficient

V

ersion CS

,

FEP

SRef.: 21821085-0/A

Issue 02/99 3-4

3.3 - DESCRIPTION OF REAR PANEL (fig. 3-4)

Figure 3-4 - ULTIMA 600 / REAR PANEL

1. On/Off switch with mains power input socket and fuse holder cover

2. Paper filter for pump protection.

3. Exhaust gas inlet for 4-cycle vehicles located in upper part of main filter (2).

4. Pump water evacuation outlet

5. Reference gas inlet

6. Connector, BB9 type, RS232 serial link

7. Connector, DB25 type, printer parallel link.

SRef.: 21821085-0/A

Issue 02/99 3-5

8. Connector, mini DIN type, keyboard link.

9. Connector, DIN type, temperature sensor link.

10. Connector, DB9 type, OBD vehicle link

11. Connector, DIN type, speed sensing clamp link for first cylinder of gasoline vehicles.

12. Connector, DB15 type, opacimeter cell link

13. Connector, DIN type, piezo speed sensing clamp link for Diesel vehicles.

14. Mains female connector to be used only for power supply of opacimeter cell

4030-0920.

15. Gas outlet.

16. Gas outlet if Nox option is used.

17. Cell end-of-protection filter.

18. First paper filter in particle filtering line, placed vertically.

19. High capacity bowl containing vyon filter cartridge.

20. Machine characteristics label.

21. O2 cell seal label.

22. Machine nameplate.

23. Punching plate.

24.Machine sealing device.

25.Air and heat evacuation vents.

26.EC marking label.

SRef.: 21821085-0/A

Issue 02/99 3-6

3.4 - DESCRIPTION OF PNEUMATIC CIRCUIT

Gas circ.drw

B

4

3

10

7

9

5

6

15

1

2

16

8

13

12 11

A

C

D

E

14

Figure 3.5 - Pneumatic circuit

Table of contents