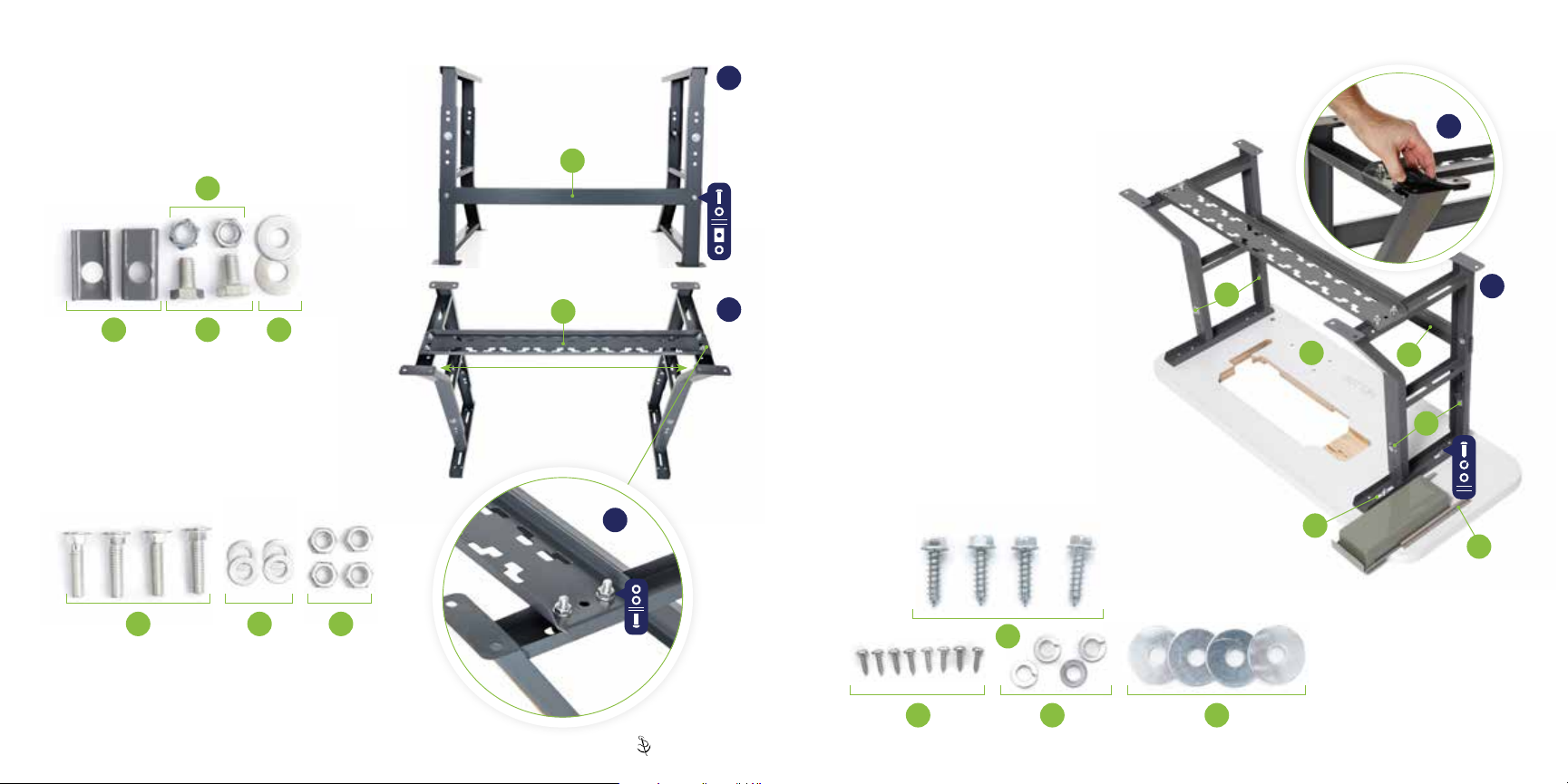

15

17

16

18

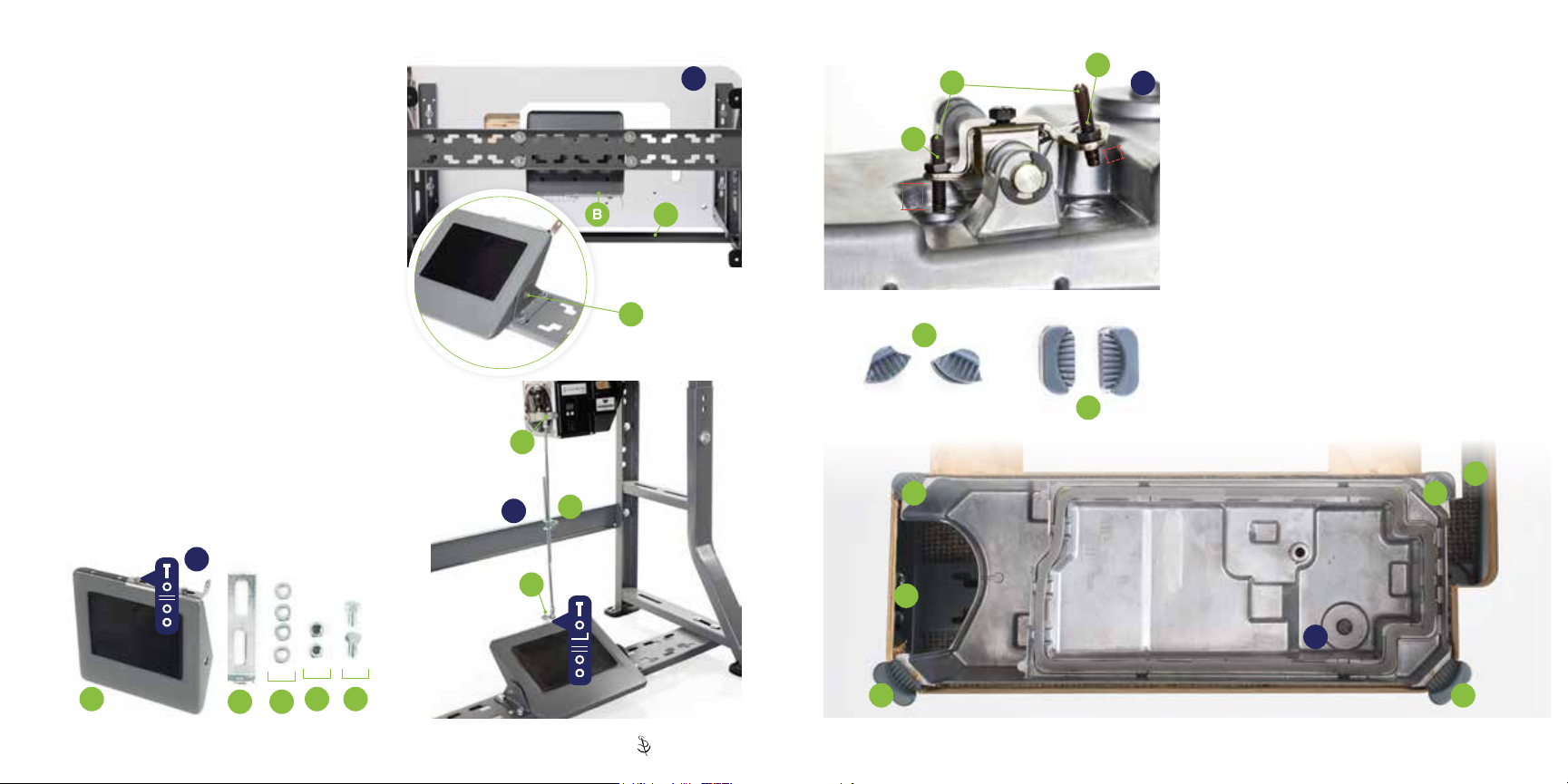

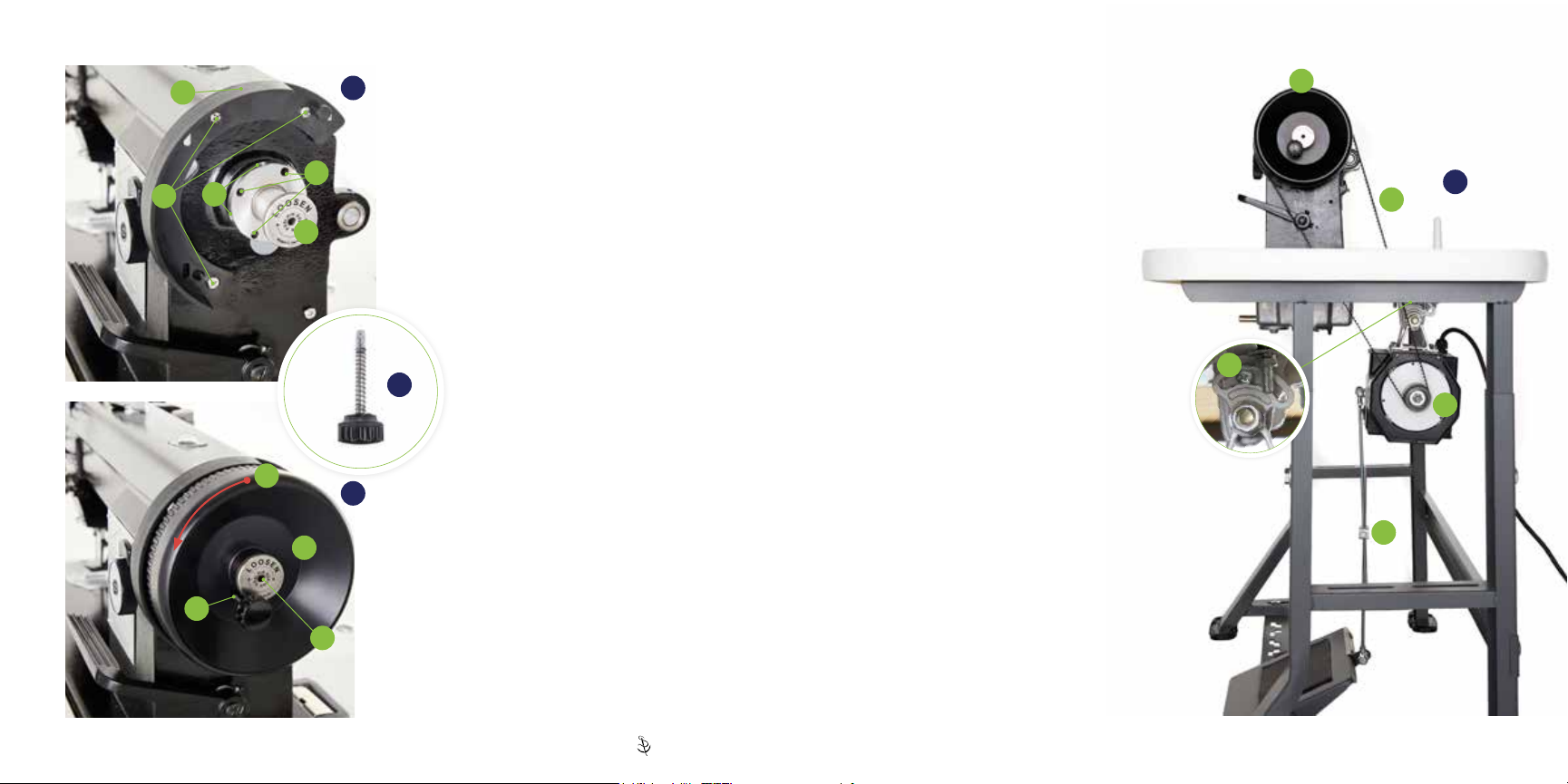

Securing the Stitch PRO

Balance Wheel

Remove the three screws (A) for the belt cover

installation. Position the C-shaped belt guard

(B) and reinstall the screws, making sure

washers are positioned as shims behind the

guard to keep it from being bent out of shape.

Unscrew the reverse-threaded Posi-Pin®nut

(C). Slide the Stitch PRO Balance Wheel (D)

onto the bushing, making sure it does not

interfere with the belt guard. If the wheel

hits the guard, reposition the washers

placed under the C-shaped belt guard

or move the bushing out further by

loosening the set screws in the bushing

ange (E).

Push the Posi-Pin®(16) through the

hole in the balance wheel (F). While

maintaining pressure on the Posi-Pin,

rotate the balance wheel (G) until the

Posi-Pin locks into one of the balance wheel

bushing holes (H). Rotation of the balance

wheel will now cause the machine to function.

To disengage the machine (for bobbin winding),

pull the Posi-Pin out of the balance wheel. The

balance wheel will now rotate without operating

the machine. Push the Posi-Pin into the hole at

the center of the Posi-Pin nut (I) to store.

Belt Adjustment for the

Workhorse®Servo Motor

Before installing the drive belt (J), loosen the

screw (K) to allow the Workhorse Servo Motor to

freely pivot.

With the machine tilted back, slip the drive belt

over the balance wheel track (L) and guide it

onto the motor pulley (M) then carefully lower

the machine.

Pivot the motor back to tighten the belt. Proper

adjustment of the belt results in 3/8 inch of slack

when pressed by nger at its center. Retighten

set screw (K). The Linkage Bar (N) may also

need to be readjusted.

Once installed, the belt should not touch the

table and should be centered on the track of

both the balance wheel and motor pulley. Adjust

the positioning of the motor left or right by

loosening the bolts attaching the motor to the

table.

Once the motor is in the correct position and all

bolts are tightened, tilt the machine back and

remove the belt so the pulley bracket can be

installed.

Before Continuing: See “Installing the Pulley

Cover” in the Workhorse instructions.

A

H

C

G

D

I

F

N

M

K

J

L

B

E

7 | Sailrite.com Fabricator®Assembly Instructions | 8

Standard Fabricator®Assembly Standard Fabricator®Assembly