Table Of Contents

Sewing Machine Safety............................................... 1

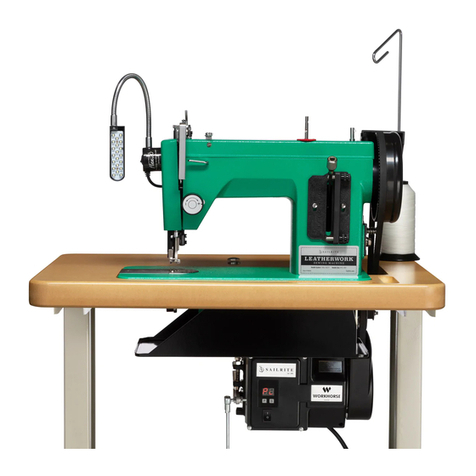

Sailrite Fabricator Set-Up .......................................... 2

Power Stand Assembly .............................................. 3

Installing the Drawer................................................... 5

Installing Rubber Foot Pads ....................................... 6

Installing the Treadle .................................................. 7

Installing the Linkage Bar ........................................... 8

Oil Pan and Machine Installation................................ 9

Check Motor Rotation............................................... 11

Securing the Stitch PRO Balance Wheel ................. 12

Belt Adjustment for the Workhorse Servo Motor ...... 13

Attaching the Balance Wheel Belt Cover ................. 14

Attaching the Bobbin Winder.................................... 15

Mounting the Led Light............................................. 16

Mounting the Thread Stand...................................... 16

Installing the Knee Lift Assembly.............................. 17

Check the Machine for Operation............................. 18

Auto Lubrication .......................................................19

Manual Oiling ...........................................................21

Coordinating the Needle, Thread and Material

Installing Needles ..................................................... 25

Thread Recommendations ....................................... 26

Preparing to Sew

How to Wind a Bobbin.............................................. 28

Bobbin Thread Winding Adjustment ......................... 30

Removing and Installing the Bobbin Case ............... 31

How to Thread the Bobbin........................................ 32

Threading the Sewing Machine................................ 33

Pulling Up the Bobbin Thread................................... 35

Sewing with the Sailrite Fabricator

Starting to Sew ......................................................... 36

Setting the Stitch Length &

Operating in Reverse ............................................... 37

Adjusting the Pressure of the Presser Feet.............. 38

Adjusting Upper Tension Assemblies ....................... 39

Adjusting Bobbin Thread Tension............................. 40

Removing Material from Under the Presser Feet..... 41

Sewing in Light to Moderate Weight Fabrics............ 41

Fabricator Maintenance

Feed Dog Height Adjustment ................................... 43

Setting the Feed Dog Position.................................. 44

Adjusting Needle Position & Clearance

Between Presser Feet.............................................. 45

Timing Between the Needle & the Rotating Hook .... 46

Adjusting the Presser Foot Lift ................................. 50

Adjusting the Vertical Lift

of the Outer Presser Foot......................................... 51

Adjusting Feed Timing of the Needle Bar,

Presser Foot and Feed Dog ..................................... 52

Stitch Length Adjustment Between

Forward & Reverse .................................................. 53

Adjusting the Thread Take-Up Spring....................... 54

Troubleshooting

Skipped Stitches....................................................... 56

Lack of Stitch Tension............................................... 57

Schematics.................................................................58

Machine Specications............................................. 75

Warranty ..................................................................... 76