Switching from

Straight to Zigzag Stitch

The stitch width adjustment lever controls

the stitch type as well as the width of your

zigzag stitch (15). When the lever is on “0” the

machine is in straight stitch. Moving the lever

to “1” produces a 1mm zigzag stitch and so

on through “5”.

DO NOT change the position of the stitch

width lever when the needle is in the fabric or

the needle may bend.

Straight Stitch

Needle Positioning

In straight stitch mode (stitch width

adjustment lever at “0”), the needle can be

moved left, right, or center (16). This is very

helpful when installing zippers where it is best

to have the needle as close to the zipper teeth

as possible. Gently push down on the lever

before moving it left, right or center. It may

also be helpful to move the balance wheel a

little while moving the lever.

DO NOT change the needle positioning when

the needle is in the fabric or the needle may

bend.

Sewing in Reverse

Position the needle fully up or fully down and

push the stitch length lever all the way down.

Hold the lever down until the reverse sewing

is completed. The lever is spring loaded and

will return to its forward position when you

release it. When the machine is operating at

1/4-speed or faster, reverse can be engaged

on the y.

DO NOT rotate the balance wheel in the

wrong direction. Always turn it towards you

(from the top) to avoid thread jams in the

lower mechanism.

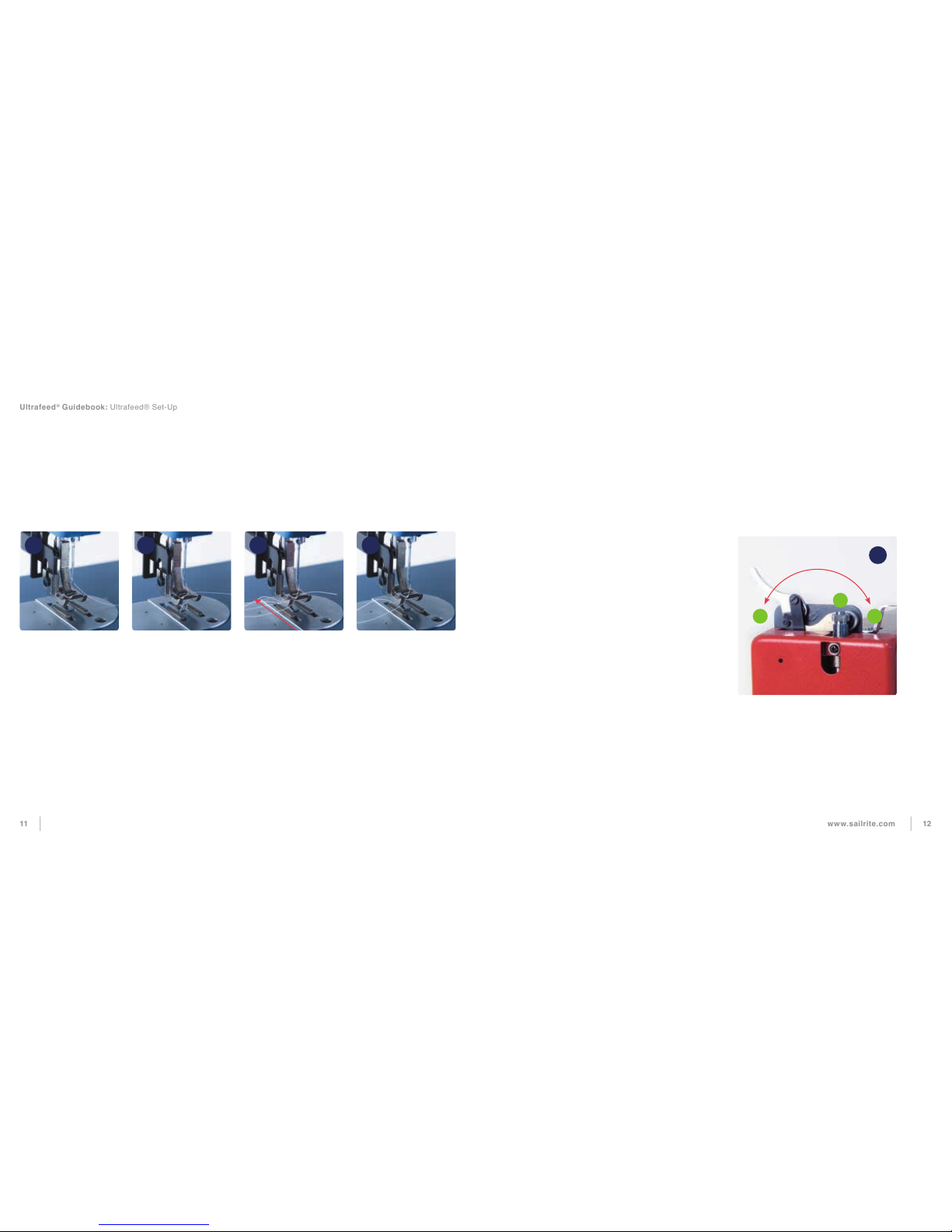

Turning Corners

First turn the balance wheel toward you until

the needle is at its lowest point. Then lift the

presser foot, turn the material to the new

direction (the needle acts as an axis), drop

the foot and start sewing in the new direction.

DO NOT attempt to change sewing directions

when the machine is at rest with the needle

positioned mid-stroke. This will cause a

skipped stitch or needle deection.

Rotating the fabric while the machine is at

rest with the presser foot down may bend the

needle.

Applies to LSZ-1 Model Only

Forward Feed

Reverse Feed

0 mm

Regulating Stitch Length

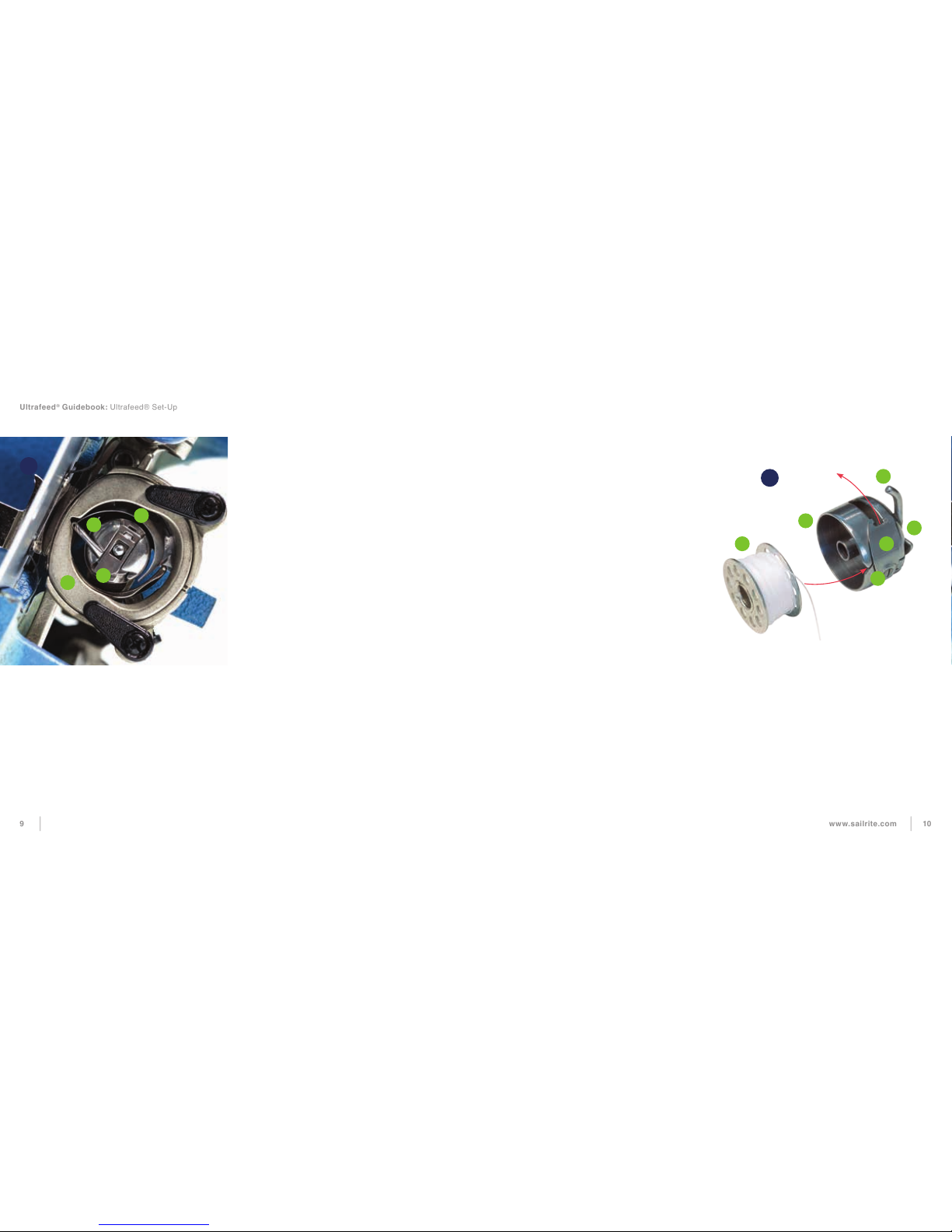

The EZ Set Stitch Length Plate (14) sets both

forward and reverse stitch length. To set the

stitch length, loosen the two thumb screws

(A), slide the posts up or down and tighten

the screws. The thumb screw stops (B)

restrict the movement of the Feed Regulator

Lever (C), which is spring loaded to always

rest against the upper stop.

B

C

A

15

16

+6 mm

Longest

Forward

+6 mm

Longest

Reverse