Table of Contents

Ultrafeed Safety���������������������� 1

Machine Damage Prevention�� 2

WorkerB®Speed Settings������� 3

Preparing to Sew�������������������� 4

Choosing Thread Size �����������������4

Needle Types ���������������������������5-6

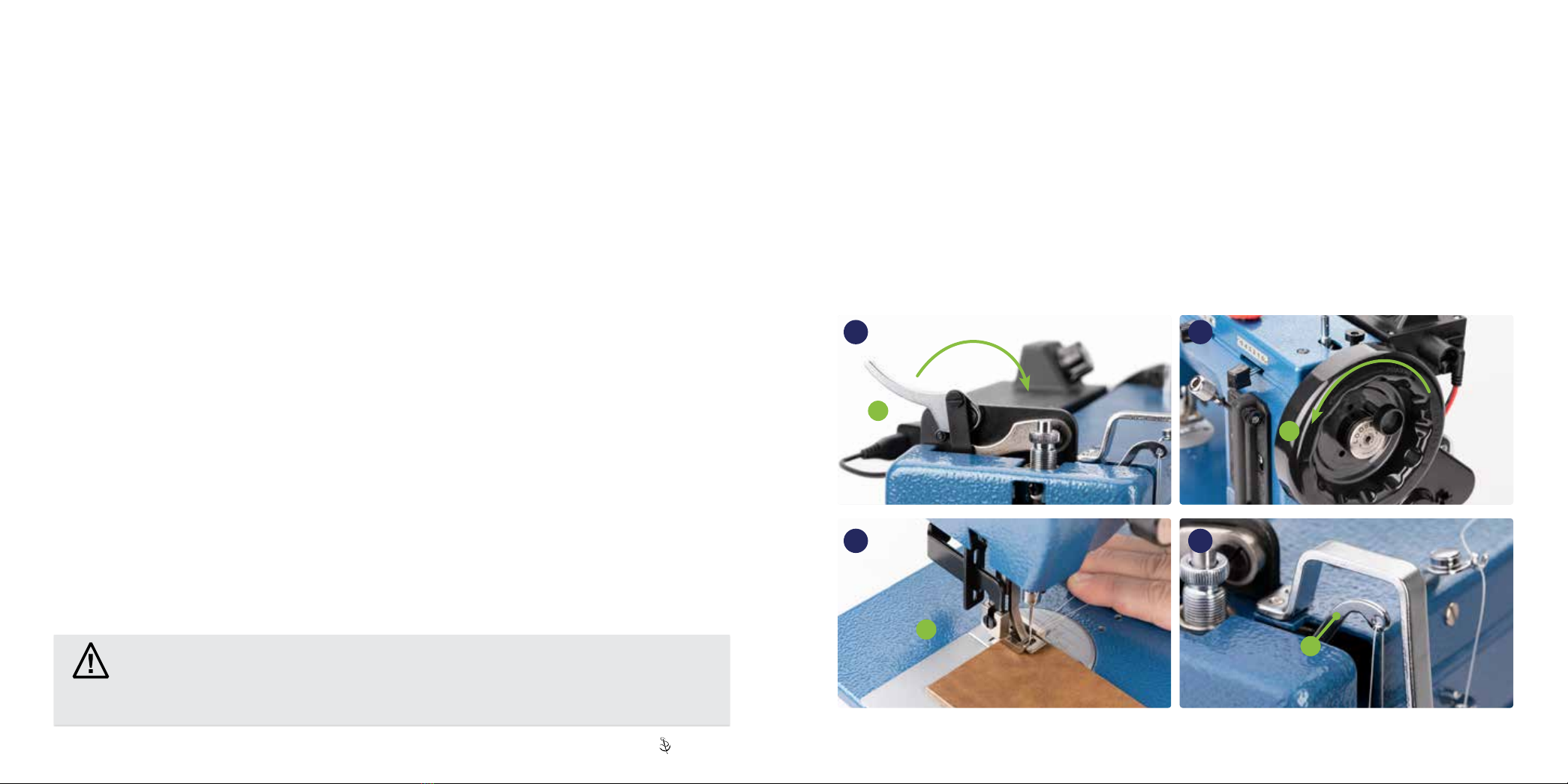

Needle Installation��������������������7-8

Presser Feet & Feed Dog

Installation������������������������������9-10

What Is the Posi-Pin®Safety

Shear? ����������������������������������� 11-12

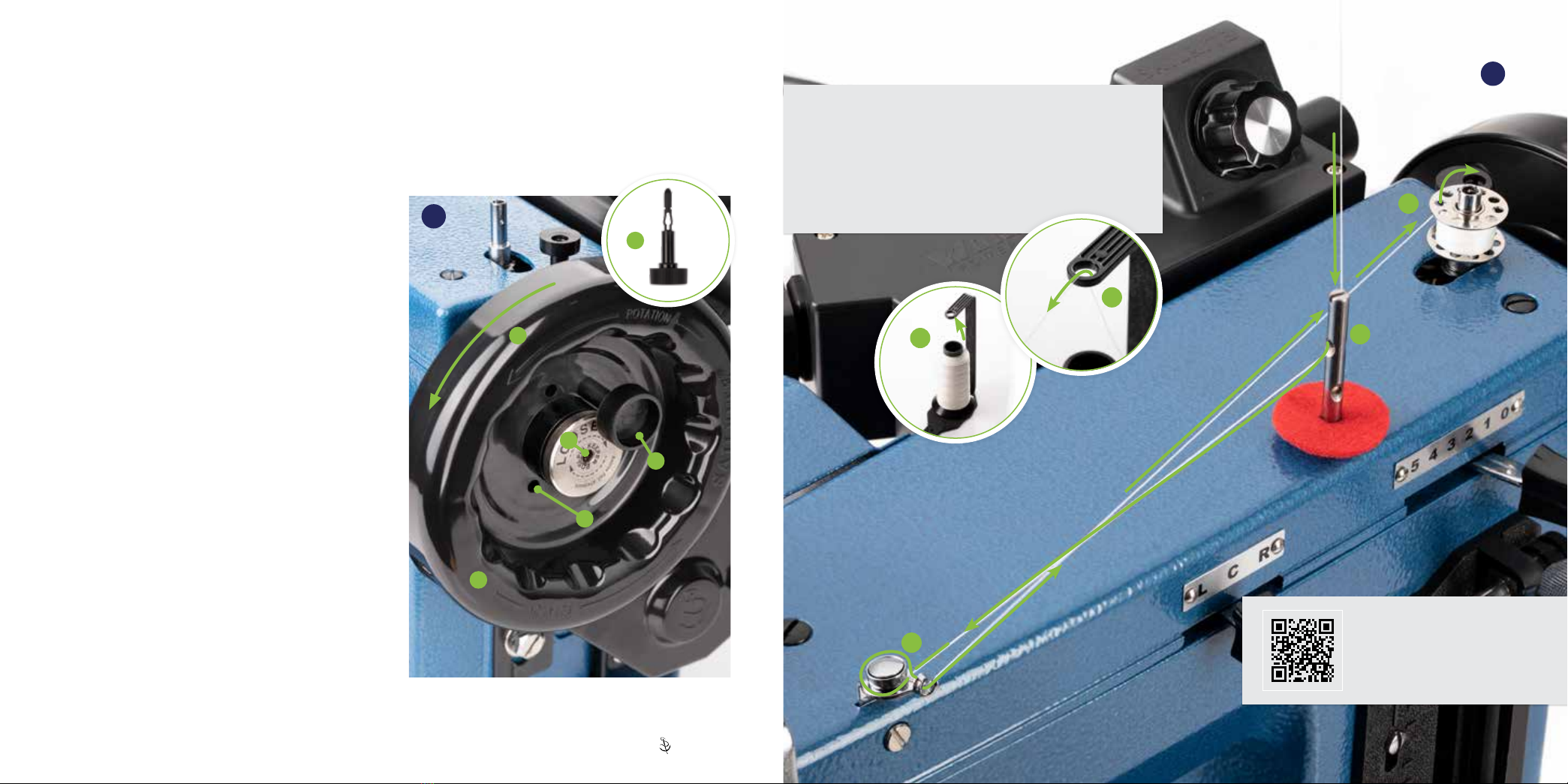

Winding Bobbins����������������������13-14

Threading the Machine������������� 15-16

Removing & Installing Bobbin Case��17

Installing Bobbin in Bobbin Case ���������������18

Picking Up Bobbin Thread ������������������������� 19

Using the Ultrafeed ��������������������������������20

Starting to Sew������������������������������������������20

Regulating Stitch Length ���������������������������21

Sewing in Reverse�������������������������������������21

Turning Corners�����������������������������������������22

Switching From Straight to Zigzag Stitch ��� 22

Straight Stitch Needle Positioning��������������22

Thread Tension Adjustment �������������������23

Advanced Thread Tension Adjustment �� 24

Adjusting Presser Foot Tension ������������ 25

Removing Material From Under the

Presser Foot�������������������������������������������26

Ultrafeed Maintenance ���������������������������27

Lubrication ������������������������������������������� 27-30

Troubleshooting the Ultrafeed ��������������� 31

Proper Needle Orientation & Installation���� 32

Replacing the Take-Up Spring ������������������� 33

Material Surface Is Being Damaged ���������� 34

If Posi-Pin®Safety Shear Breaks ��������������� 35

Removing the Hook to Clean the Shuttle

Race Guide Shaft & Free Thread Jams ����� 36

Skipped Stitches����������������������������������� 37-38

Thread Issues��������������������������������������� 39-42

Needle Issues�������������������������������������������� 43

Bobbin Winding Issues ������������������������������ 44

Ultrafeed Timing�������������������������������� 45-54

Schematics���������������������������������������� 55-66

Specifications ����������������������������������� 67-68

Warranty �������������������������������������������� 69-70

Your Sewing Journey

Starts Today!

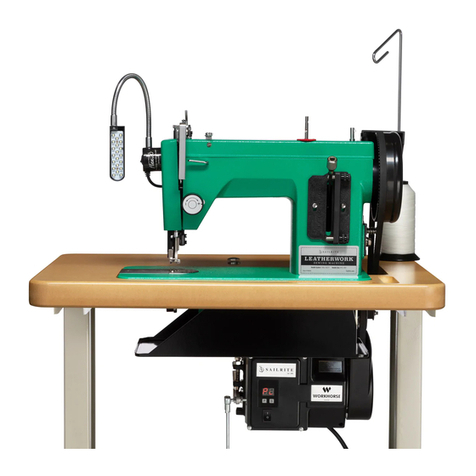

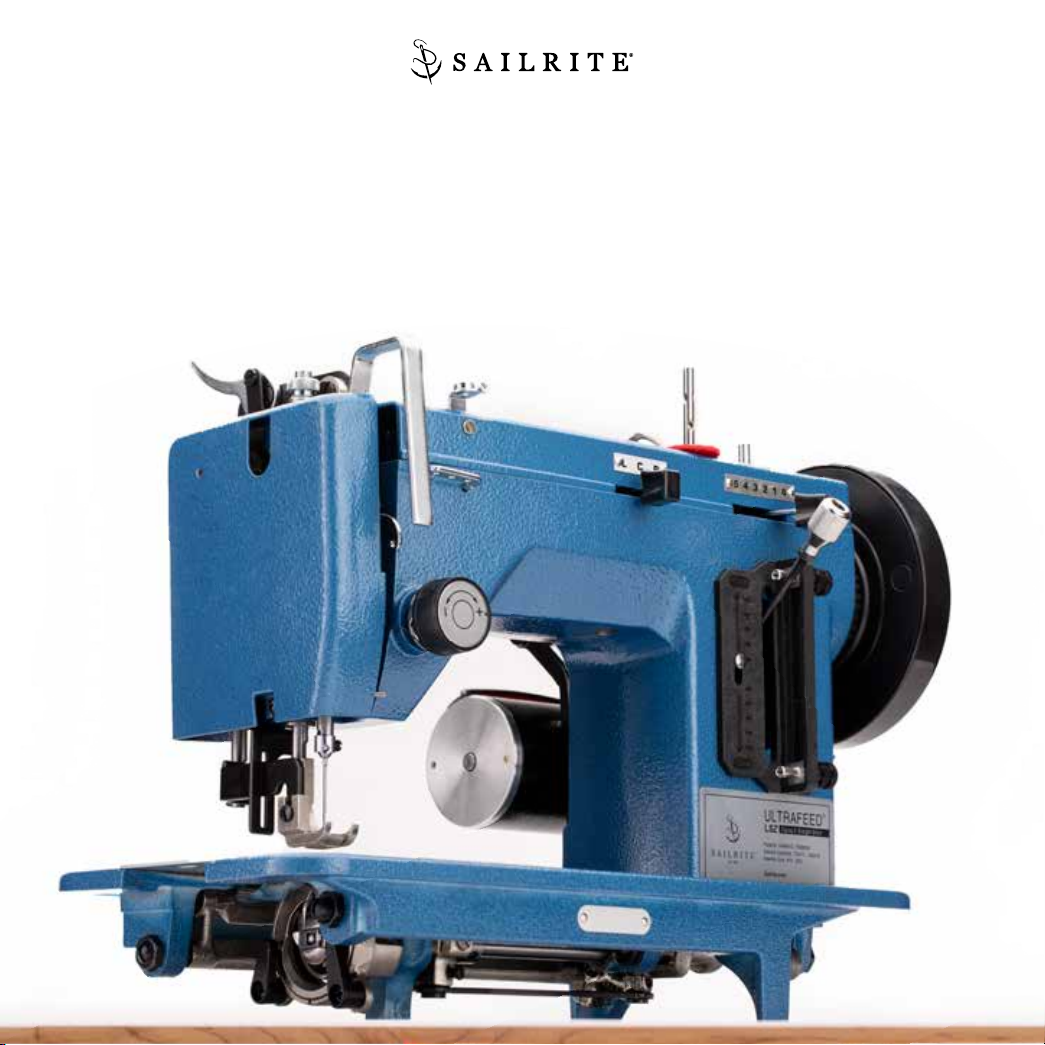

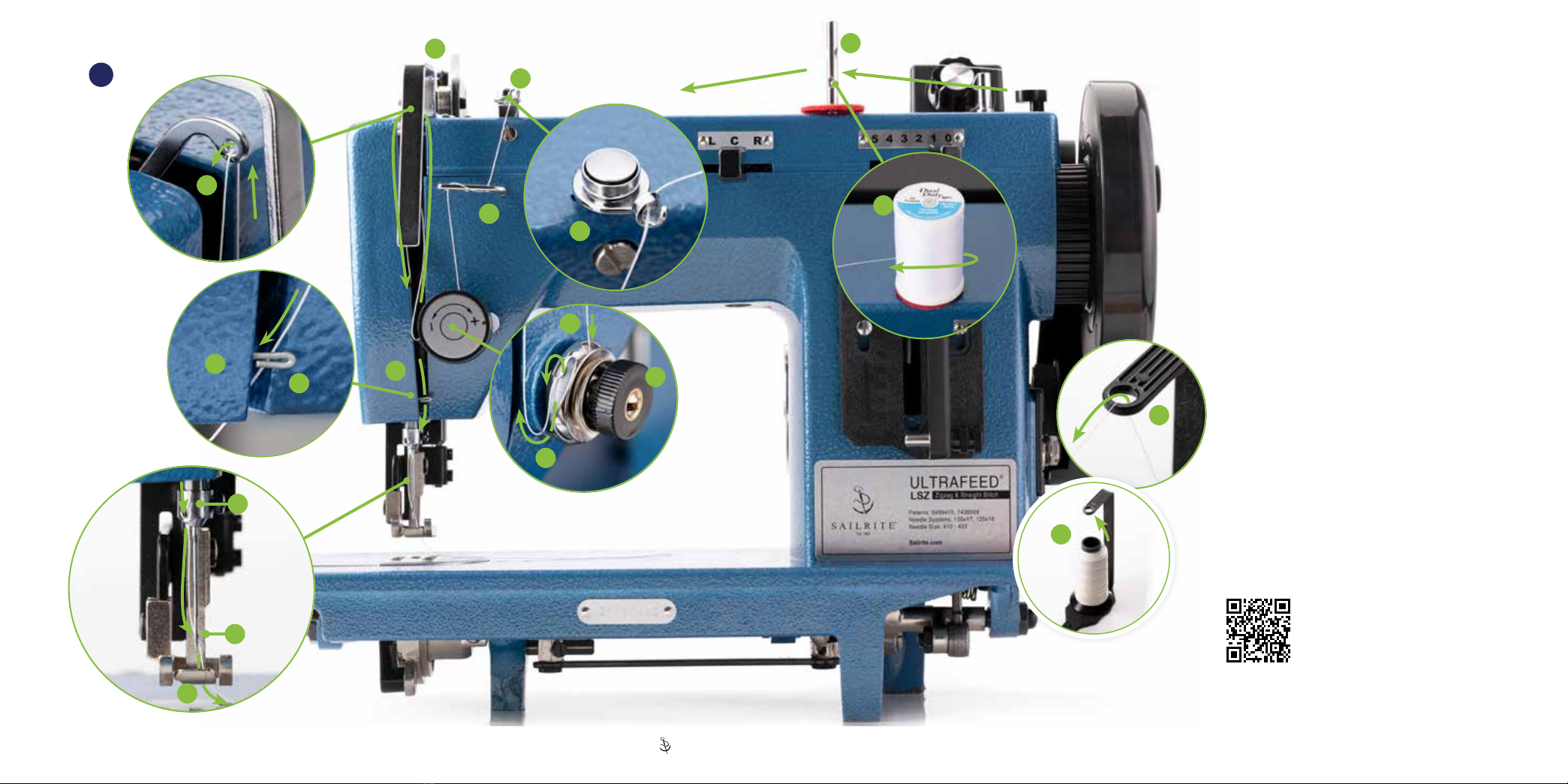

Congratulations on your new Ultrafeed®Sewing

Machine. Inside this guidebook you'll nd detailed

instructions, photos and videos on how to prepare

and use your machine, as well as troubleshooting and

maintenance advice�

To watch all of the setup and maintenance videos in this

guidebook, please visit Sailrite�com/LSZ-Guidebook-Videos

for a complete video playlist�