Table of Contents

Leatherwork Safety ����������������������������������� 1

Machine Damage Prevention��������������������� 2

Workhorse®Safety Precautions ���������������� 3

Changing Motor Rotation�������������������������� 4

Workhorse Speed Settings������������������������ 5

Preparing to Sew��������������������������������������� 6

Choosing Thread Size �����������������������������������6

Needles���������������������������������������������������������7

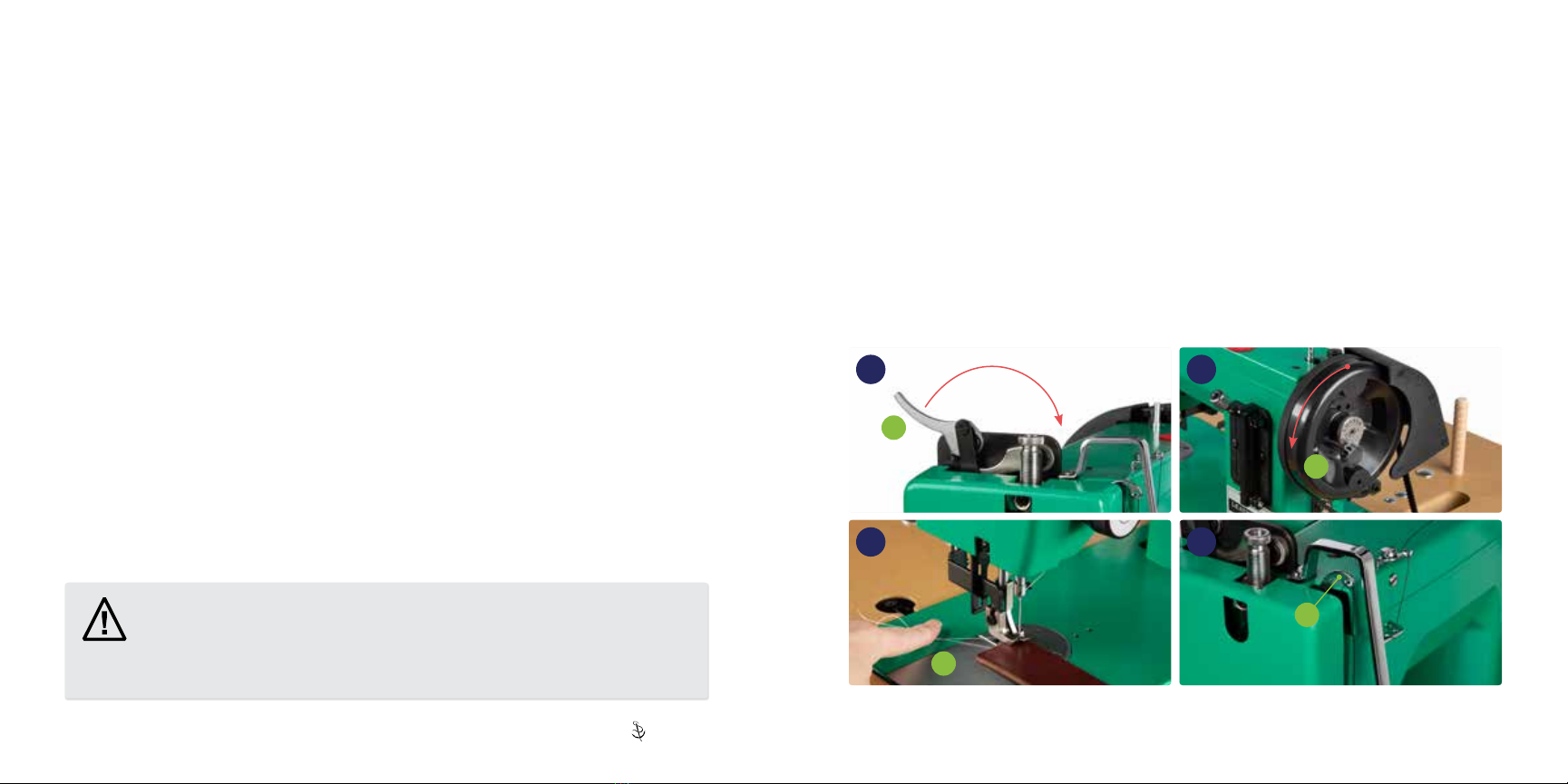

Winding Bobbins �������������������������������������������9

Threading the Machine�������������������������������� 11

Removing & Installing Bobbin Case�������������13

Installing Bobbin in Bobbin Case �����������������14

Picking Up Bobbin Thread ���������������������������15

Using the Leatherwork ���������������������������� 16

Starting to Sew��������������������������������������������16

Regulating Stitch Length �����������������������������18

Sewing in Reverse ��������������������������������������18

Setting Equal Forward &

Reverse Stitch Length ���������������������������������18

Turning Corners ������������������������������������������18

Thread Tension Adjustment �������������������������19

Advanced Thread Tension Adjustment���������20

Adjusting Presser Foot Tension �������������������21

Removing Material From Under

the Presser Foot������������������������������������������21

Sewing Fabric ���������������������������������������������22

Leatherwork Maintenance ����������������������� 23

Lubrication ��������������������������������������������������23

Troubleshooting the Leatherwork����������� 27

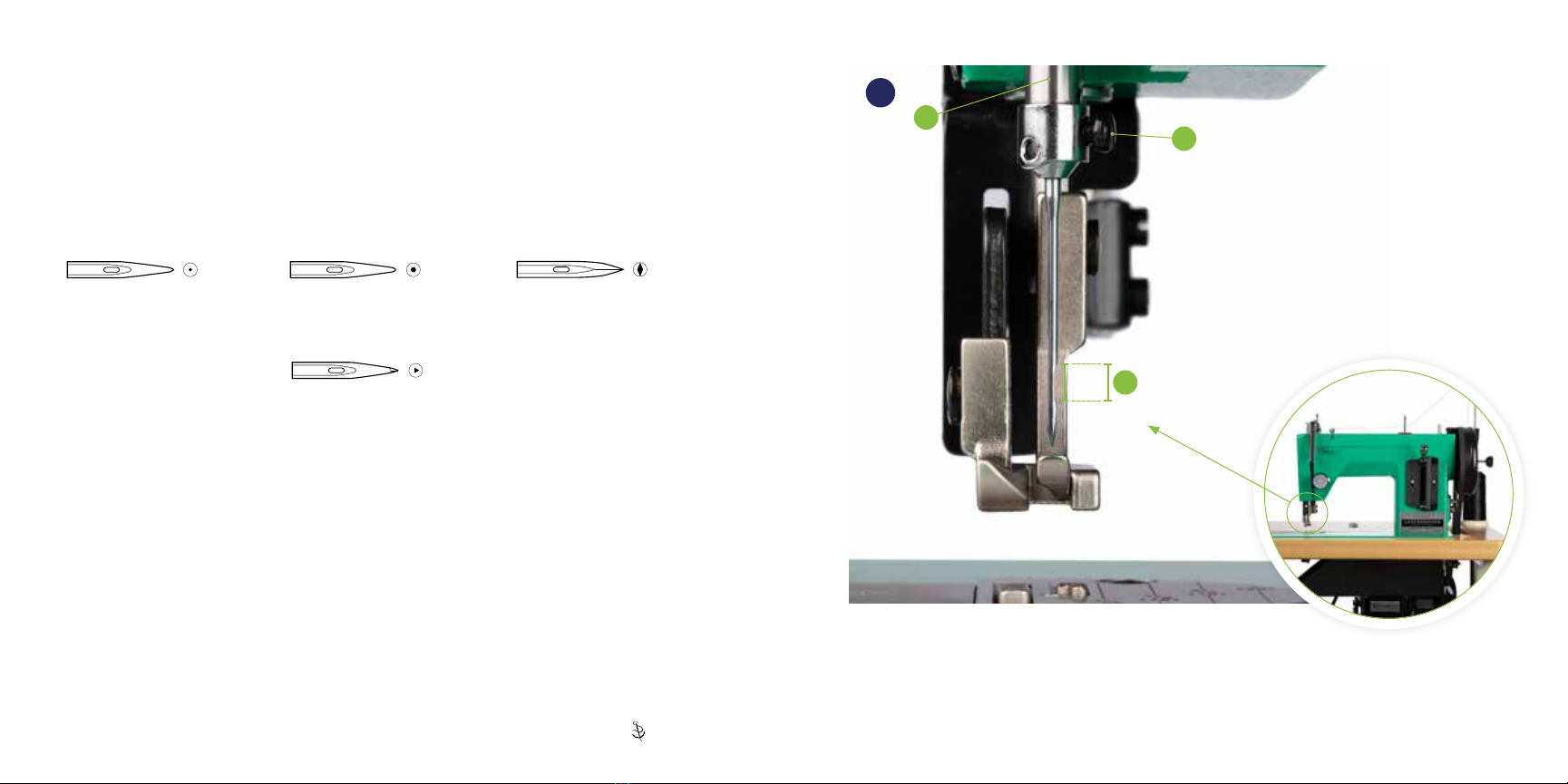

Proper Needle Orientation & Installation������27

Replacing Take-Up Spring ���������������������������28

Belt Issues ��������������������������������������������������29

Material Surface Is Being Damaged ������������29

Clutch Will Not Disengage���������������������������30

Removing the Hook to Clean the Shuttle

Race Guide Shaft & Free Thread Jams �������30

Skipped Stitches������������������������������������������31

Thread Issues ���������������������������������������������33

Needle Issues ���������������������������������������������37

Bobbin Winding Issues ��������������������������������38

Leatherwork Timing ������������������������������� 39

Schematics���������������������������������������������� 49

Specifications ����������������������������������������� 63

Warranty �������������������������������������������������� 68

Sew like a pro with Sailrite®

For in-depth information on use and

maintenance of your new Leatherwork®

Sewing Machine, please refer to our free

video at Sailrite�com/leatherwork-use or

search #300526XHT at Sailrite�com�