VISION-LITE® / VISION-LITE II® PROCESSING GUIDELINES

MAY 2022

5

1. General

VISION-LITE® is a coated glass with very low reflectance (1%). According to the product reference, it is

available in annealed monolithic with coating on one or two sides or laminated with coatings on both

sides (see below). VISION-LITE® is produced on DIAMANT® base glass for architectural applications.

The two exterior sides of the glass have a transparent coating of oxides or a coating of metallic nitrides

which, by reducing the reflectance of the glass surface, enhance the glass transparency and visibility of

objects seen through it.

As compared to the standard glass, VISION-LITE® has:

• Higher transparency

• Extremely low light reflectance

• High light transmittance

• Very high colour contrast

VISION-LITE® II is the to-be-tempered version, it can be toughened, heat-strengthened or curved.

The VISION-LITE® range includes the following types of products:

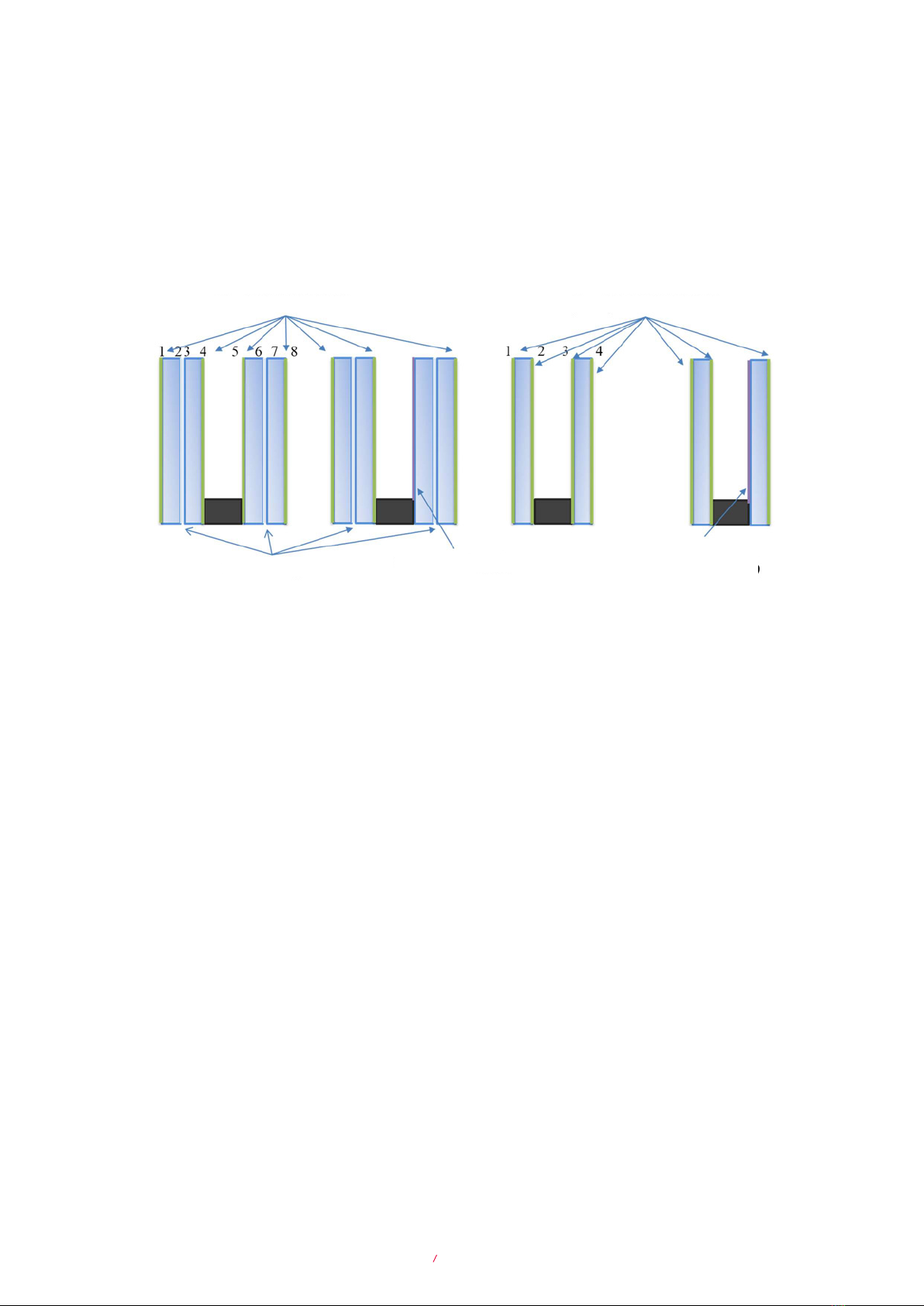

• SEMI VISION-LITE® monolithic glass - with coating on one side of the glass only, intended for

lamination.

• STADIP VISION-LITE® laminated glass - with two SEMI VISION-LITE® sheets assembled by means of

one or several PVB layers. The sheets are assembled so that the coating is on the exterior, therefore

the laminate has coatings on both sides.

• VISION-LITE® II monolithic glass - with coating on both sides of the glass, meant to be tempered

• SEMI VISION-LITE® II monolithic glass - with coating on one side of the glass only, intended for

tempering then lamination.

VISION-LITE® & VISION-LITE® II can be used in single or double glazing unit.

VISION-LITE® is mainly used in retail shops and museums as display case glazing, and in exteriors as

shop windows or balustrades. VISION-LITE® can also be used for other specific external applications like

lobby / ground floor glazing and roof-top restaurants. VISION-LITE® is however not recommended for

façade projects, including multi-storey shop windows.

VISION-LITE® II is recommended for specific applications requiring tempered glass, it can be used as

external glazing on limited surface. Building applications of VISION-LITE II® must be assessed depending

on the project. VISION-LITE® II is not recommended for high rise front façade (curtain wall). Contact

your sales representative for more information.

VISION-LITE® & VISION-LITE® II cannot be mixed on the same glazing surface.

VISION-LITE® range meets the requirements of Class A products as defined in the European standards

EN1096-1 and EN1096-2. The eciency of the anti-reflective eect will be maximum in the simple glazing.

For complete performance data, please refer to the Glass Guide, our commercial documentations and

our website www.saint-gobain-glass.com.

To improve customer satisfaction, we constantly improve the quality of our coatings. This could lead to

improvement in the processability of our coating, so please make sure you have an up-todate version

of these guidelines.

1.1. PRODUCT DESCRIPTION

VISION-LITE® range products are usually available in standard thicknesses and sizes. For more details, please

refer to the relevant product documentation from Saint-Gobain Glass or contact your local sales service.

1.2.1. Thickness and dimensions

1.2. THICKNESS, DIMENSIONS AND TOLERANCES