EN | 9RIRS 400-700 V EKO 3.0 v2019.06

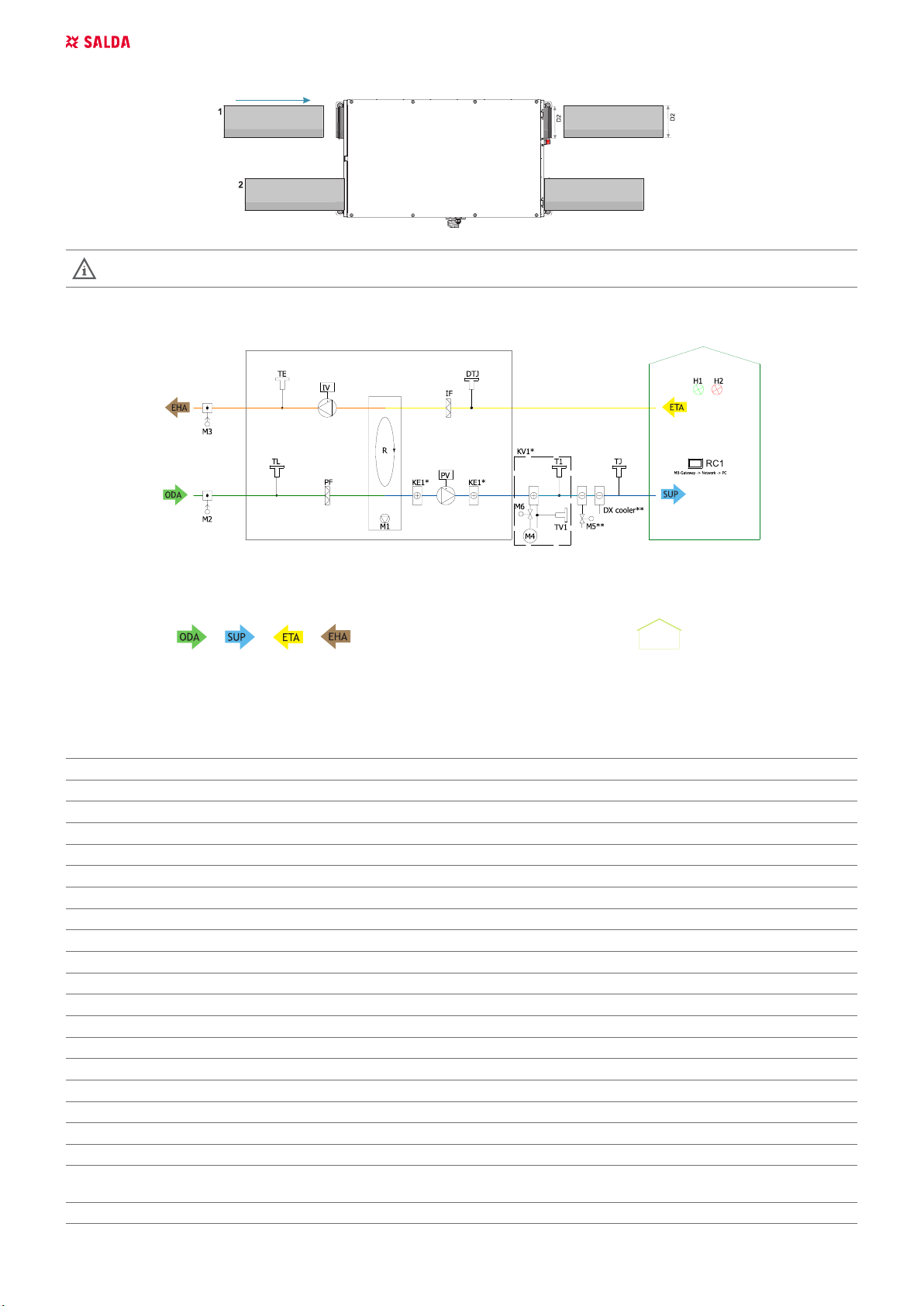

FPP Fireplace protection H2 Alarm indication output

System mode switch (START/STOP) Fans speed switch (BOOST)

* Component/posibility to connect it depends on model. For more information please, check the manual

16.CONNECTION OF THE UNIT TO ELECTRIC NETWORK

• Supply voltage to the unit must be connected by a qualied specialist following the manufacturer’s instructions and eective safety instructions.

• The unit’s power network voltage must correspond to electrotechnical parameters of the unit indicated in the technical decal.

• The unit’s voltage, power and other technical parameters are provided in the unit’s technical decal (on the unit casing). The unit must be connect-

ed to the voltage plug socket of the grounded power network in compliance with the eective requirements.

• The unit must be earthed according to the rules on installing electrical equipment.

• It is prohibited to use extension wires (cables) and power network plug socket distribution devices.

• Prior to carrying out any ventilation unit installation and connection activities (until its hand-over to the customer), the unit must be disconnected

from the power network.

• After installation of the ventilation unit, the power network plug socket must be accessible at any time and disconnection from the power network

is performed through the two-pole circuit breaker (by disconnecting phase pole and neutral).

• The unit must be thoroughly checked against damages (execution, control, measurement nodes) during transportation before it is connected to

the power network.

• The power cable can be replaced only by a qualied specialist upon the evaluation of the rated power and current.

The manufacturer does not assume any liability for personal injuries and property damage due to nonconformance with the

provided instructions.

17.START-UP RECOMMENDATIONS

17.1. RECOMMENDATIONS BEFORE THE START OF THE UNIT (BEFORE THE FINAL USER)

Prior to start-up the system must be thoroughly cleaned. Check whether:

• operation systems and unit elements as well as automation and automation devices were not damaged during installation,

• all electrical devices are connected to power supply and t for service,

• all necessary automation elements are installed and connected to power supply and terminal blocks,

• cable connection to terminal blocks comply with the existing power connection diagrams,

• all electrical equipment protection elements are properly connected (if they are additionally used),

• cables and wires correspond to all applicable safety and functional requirements, diameters, etc.,

• earthing and protection systems are properly installed,

• condition of all seals and sealing surfaces are proper.

17.2. POSSIBLE FAULTS AND TROUBLESHOOTING

FAILURE CAUSE EXPLANATION / CORRECTIVE ACTIONS

Unit is not operating

No supply voltage Check whether the device is connected to the

power network

Protection device is o or a current

leakage relay is active (if installed by the

installer)

Switch on only if the unit condition has been

evaluated by a qualied electrician. If the sys-

tem failed, the failure MUST BE rectied prior

to switching it on.

Air supply heater or pre-heater is not operat-

ing or malfunctioning (if installed)

Too low air ow in air ducts activates auto-

matic

protection

Check if air lters are not clogged

Check if fans are rotating

Manual protection is activated

Possible heater or unit failure. MUST contact

the servicing sta for failure detection and its

elimination.

Too low air ow at rated fan speed Clogged supply and/or extract air lter(s) Filter replacement needed

Filters are clogged and no message is shown

on the remote control

Wrong time in lter timers or their switch is

broken, or its pressure is set improperly.

Shorten lter timer time till the message of

clogged lters or replace the pressure switch

of the lters, or set their proper pressure.

18.MAINTENANCE

Unplug unit from mains rst and wait for 2 minutes (till fans fully stop) before opening the covers.

18.1. FILTERS

Dirt increases air resistance in the lter, therefore less air is supplied into the premises.

- It is advisable to change the lters every 3-4 months, or in accordance with the readings of lter contamination sensor. (Sensor PS 600 is inte-

grated in the unit).