5

2. SAFETY INFORMATION.

2.1. USING THIS MANUAL.

The documentation of any standard equipment is

available to the customer on our website for download

(www.salicru.com).

•For equipment “powered by socket”. This is the intended

portal for obtaining the user manual and safety instructions

EK266*08.

•For equipment "with permanent connection", connection to

terminals. Although it can be downloaded from the web-

site, a CD-ROM or Pen Drive can be delivered with the UPS

with all the necessary information for its connection and

commissioning, including EK266*08 safety instructions.

Before carrying out any action on the equipment relating to its

installation or commissioning, change of location, configuration

or manipulation of any kind, you must read the safety instruc-

tions carefully.

The purpose of the user manual is to provide information re-

garding safety and explanations of the procedures for installa-

tion and operation of the equipment. Read them carefully and

follow the steps indicated in the order established.

Compliance with the "Safety Instructions" is

mandatory and the user is legally responsible for

compliance and enforcement.

The equipment is delivered properly labelled for the correct

identification of each of the parts, which together with the in-

structions described in this user manual allows the operations

of installation and commissioning to be performed in a simple

and orderly manner without having any doubts whatsoever.

However, because the product is constantly evolving,

discrepancies or slight contradictions may arise. If in

any doubt, the labelling on the equipment itself will al-

ways prevail.

Finally, once the equipment is installed and operating, it is rec-

ommended to save the documentation downloaded from the

website, CD-ROM or Pen Drive in a safe and easy-to-access

place, for any future queries or doubts that may arise.

When a system differs from that shown in the figures in

Section 4, except when the number of modules con-

nected in parallel and/or the technical specifications

are modified, additional explanatory annexes will be

edited if deemed appropriate or necessary. These will

usually be printed on paper.

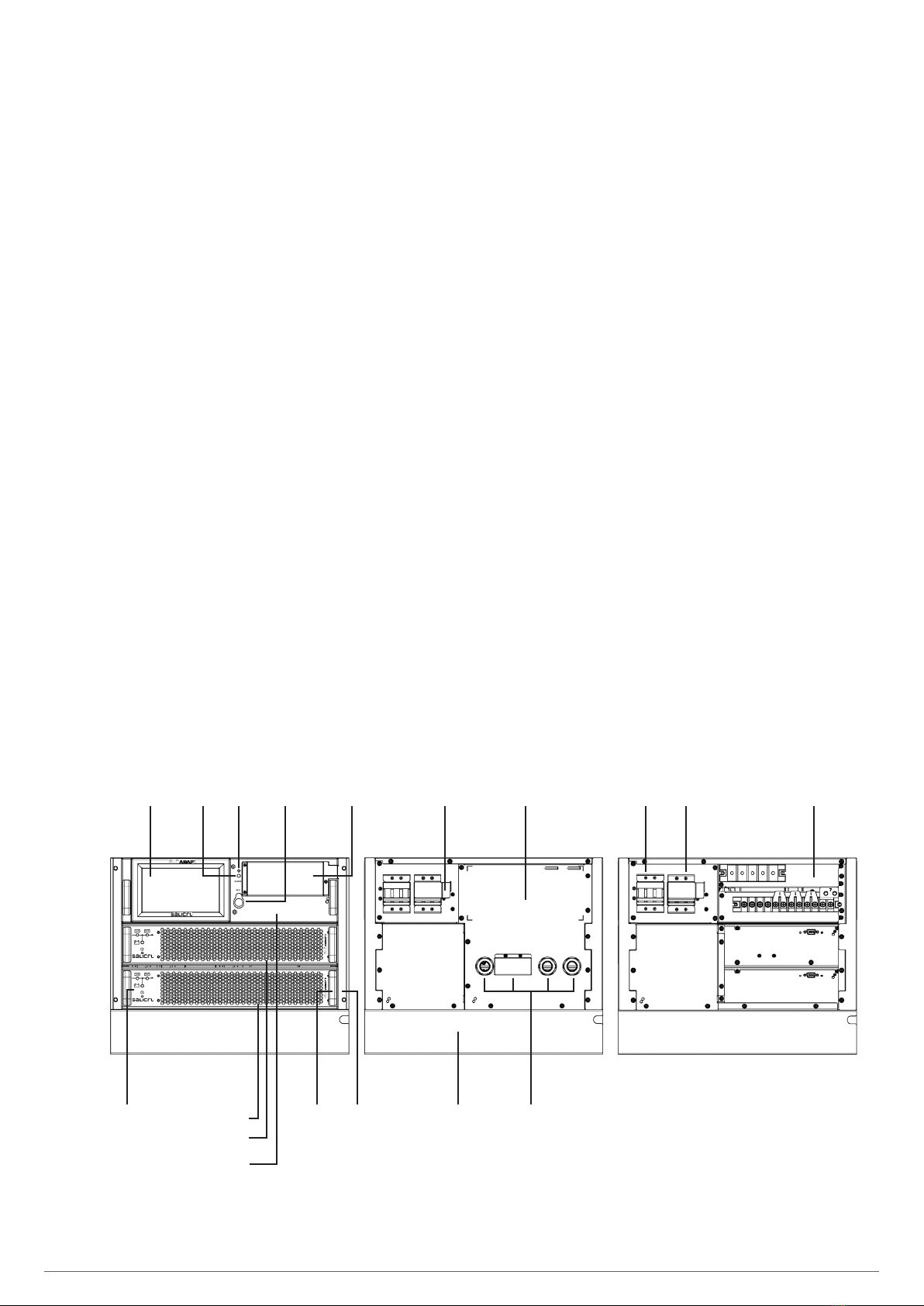

This user manual is useful for SLC ADAPT X subrack equip-

ment, with the following configurations:

•Model with two slots. It allows the installation of one or

two modules.

•Model with four slots. It allows the installation of between

one and four modules.

•Model with six slots. It allows the installation of between

one and six modules and is parallelable in turn with five

subracks.

Conceptually, they are designed to be assembled into a 19“

rack cabinet, whether they share the batteries or not.

While the customer can perform these adaptations on their

own or otherwise, we can also manufacture any configuration

on demand.

For those systems shipped from the factory and assembled in a

rack cabinet, we have the supplementary and generic EL096*00

document in which the parts (connection terminals, switching

mechanisms, etc.) and the corresponding operations are identi-

fied.

The following terms are used interchangeably in the document

to refer to:

•“SLC ADAPT X, ADAPT X, ADAPT, UPS, system, equip-

ment or unit.”.- Uninterruptible Power Supply ADAPT se-

ries of subfamily X.

Depending on the context of the phrase, it can refer either

to the actual UPS itself or to the the UPS and the batteries,

regardless of whether it is all assembled in the same metal

casing - box - or not.

•“Batteries or accumulators”.- Group or set of elements

that stores the flow of electrons by electrochemical means.

•“T.S.S.”.- Technical Service and Support.

•"Client, installer, operator or user ".- These are used

interchangeably and by extension to refer to the installer

and/or operator who will carry out the corresponding ac-

tions, and the same person may be responsible for carrying

out the respective actions when acting on behalf of, or in

representation of, same.

2.1.1. Conventions and symbols used.

Some symbols may be used and appear on the equipment, bat-

teries and/or in the context of the user manual.

For more information, see section 1.1.1 of document EK266*08

on "Safety instructions".

In the event that there are differences in relation to the safety

instructions between document EK266*08 and the user's

manual of the equipment, the latter will always prevail.

2.1.2. Safety considerations.

•While the security-related considerations will be dealt with

in more detail in Section 5, the following will be taken into

account:

Inside the battery cabinet there are accessible parts

with HAZARDOUS VOLTAGE and consequently risk of

electric shock, so they are classified as RESTRICTED

ACCESS ZONES. Therefore, the key of the battery cab-

inet will not be available to the OPERATOR or USER,

unless such person has been properly instructed.

In case of intervention inside the battery cabinet either

during the connection, preventive maintenance or re-

pair procedure, it will be taken into account that the

voltage of the battery set exceeds 400 V DC and

consequently safety measures must be taken.

Any operation of connecting and disconnecting the

cables or handling inside a cabinet will not take place

for around 10 minutes in order to allow the internal

discharge of the capacitors of the equipment. Even so,

check with a multimeter that the voltage at terminals is

less than 36 V.

In case of installation in neutral IT mode, the switches,

circuit breakers and thermal magnetic protection must

cut the NEUTRAL in addition to the three phases.

EMi3 SERVOMOTOR VOLTAGE STABILISERUSER'S MANUAL