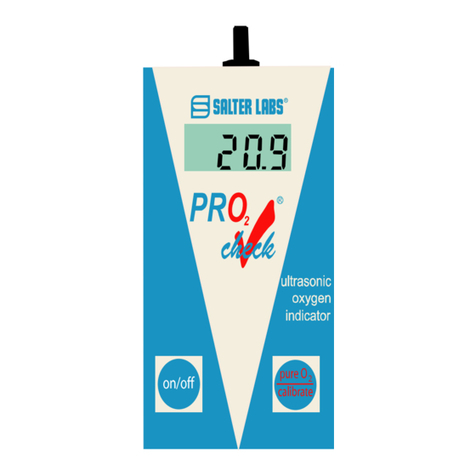

2

check ®

Ultrasonic Oxygen Indicator

INTRODUCTION

Thank you for purchasing a PRO2 check ® Ultrasonic Oxygen Indicator. The

designers of this product have years of experience in the field of oxygen

concentrator repairs. The unreliability and high cost of operation of fuel

cell analyzers led to the invention of the PRO2 check ® Ultrasonic Oxygen

Indicator.

Byrelying on a method already used in many oxygen concentrators to

trigger "Low O2" alarms – ultrasound – Salter Labs has produced a more

cost effective product to check the output of oxygen concentrators. The

PRO2 check ® Ultrasonic Oxygen Indicator responds faster, has no fuel

cell

to replace and is simpler to use than a fuel cell analyzer.

Directions for Use:

There are two (2) controls for the PRO2 check® unit:

1.

Pressing and releasing the “on/off” button will turn the unit on or off.

2.

The “pure O2 calibrate” button when pressed and held down

while connected to a compressed gas or liquid U.S.P. oxygen

(> 99.0%) source verifies that the unit is properly calibrated, thus

eliminating the need to have an outside source calibrate the unit.

Since the PRO2check® device uses ultrasound technology to check the con-

centrator operation, there has to be two modes of operation:

1.

When the unit is turned on, the software enables the unit to

measure the output of an oxygen concentrator adjusting for the

argon that passes through the sieve beds.

2.

When using the unit with the “pure O2 calibrate” button

depressed the software measures oxygen not adjusting for the

argon. When the “O2 calibrate” button is released, the unit

automatically returns to the concentrator mode and will then again

adjust for the argon and read incorrectly for pure oxygen.

We are sure that the PRO2 check® Ultrasonic Oxygen Indicator will

provide years of fast, reliable operation.

2